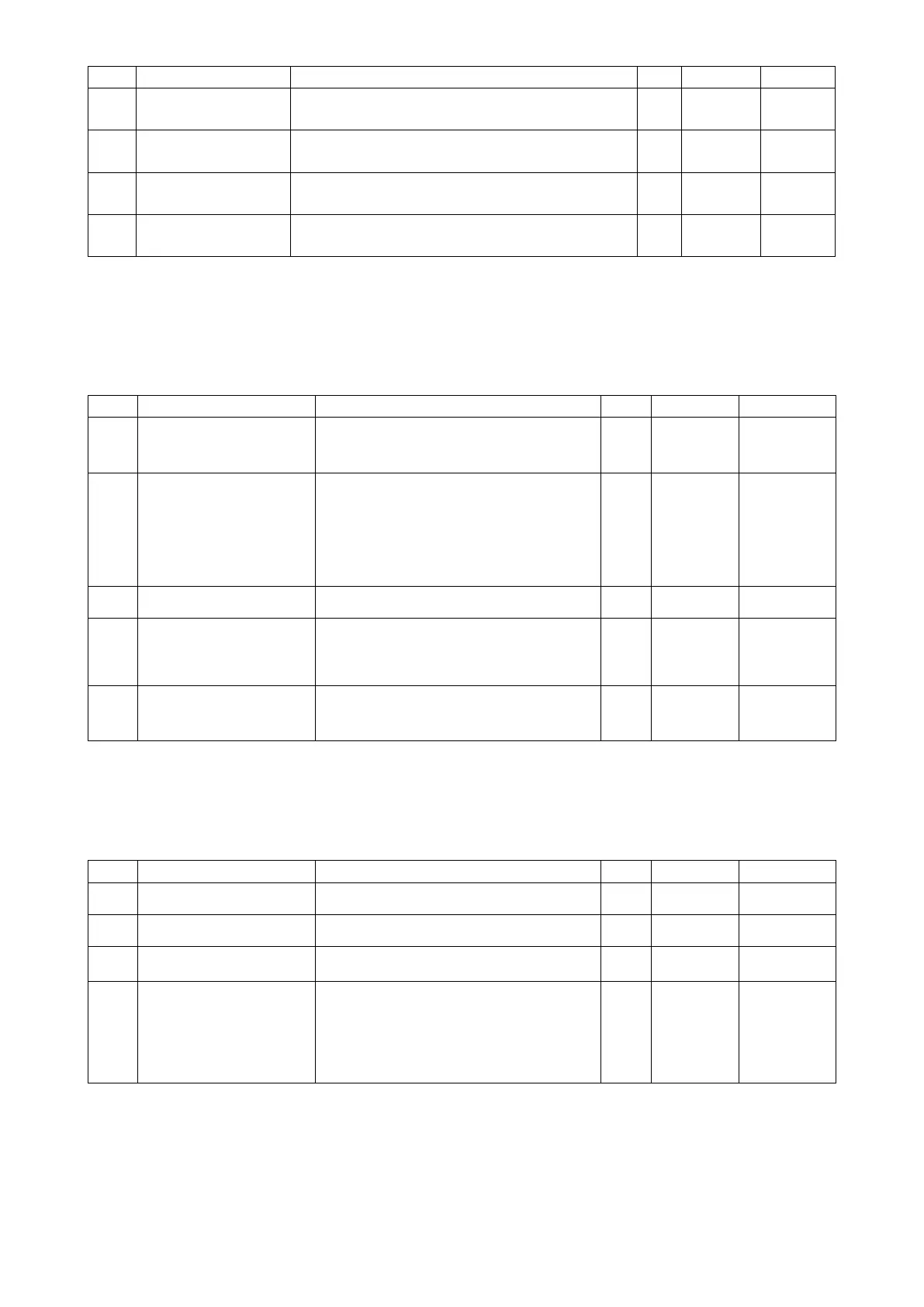

No. Item Description Level Setting range Default

J04 Selection of language for the

audio function

The language for the audio function is selected with

this function setting item.

1: Chinese

2: English

U 1-2 2

J05 Audio ON/OFF function ON/OFF of the audio guidance is set with this function

setting item.

0: All audio guidance is set to OFF

1: Only the panel operation guidance is enabled

2: All audio guidance is set to ON.

*

When this item is set to "1", the audio guidance for

"

③

At the time of operating the sewing machine;

Guidance on the production support" (

"4-3. Audio

guidance" p. 25

) is placed in OFF.

U 0-2 2

J10 Setting of brightness of the back-

light

Brightness of the backlight is set with this function

setting item.

U 1-3 3

J11 Energy saving mode Time to turn OFF the backlight of LCD when the panel

is not operated is set with this function setting item.

0: The backlight is not turned OFF

1 - 20: Time to be elapsed before turning OFF the

backlight

U 0-20(min) 0

J14 Password If the password is set to a number other than "0000",

the password entry screen will be displayed before

displaying the function setting screen by pressing the

M switch.

S 0000-9999 0

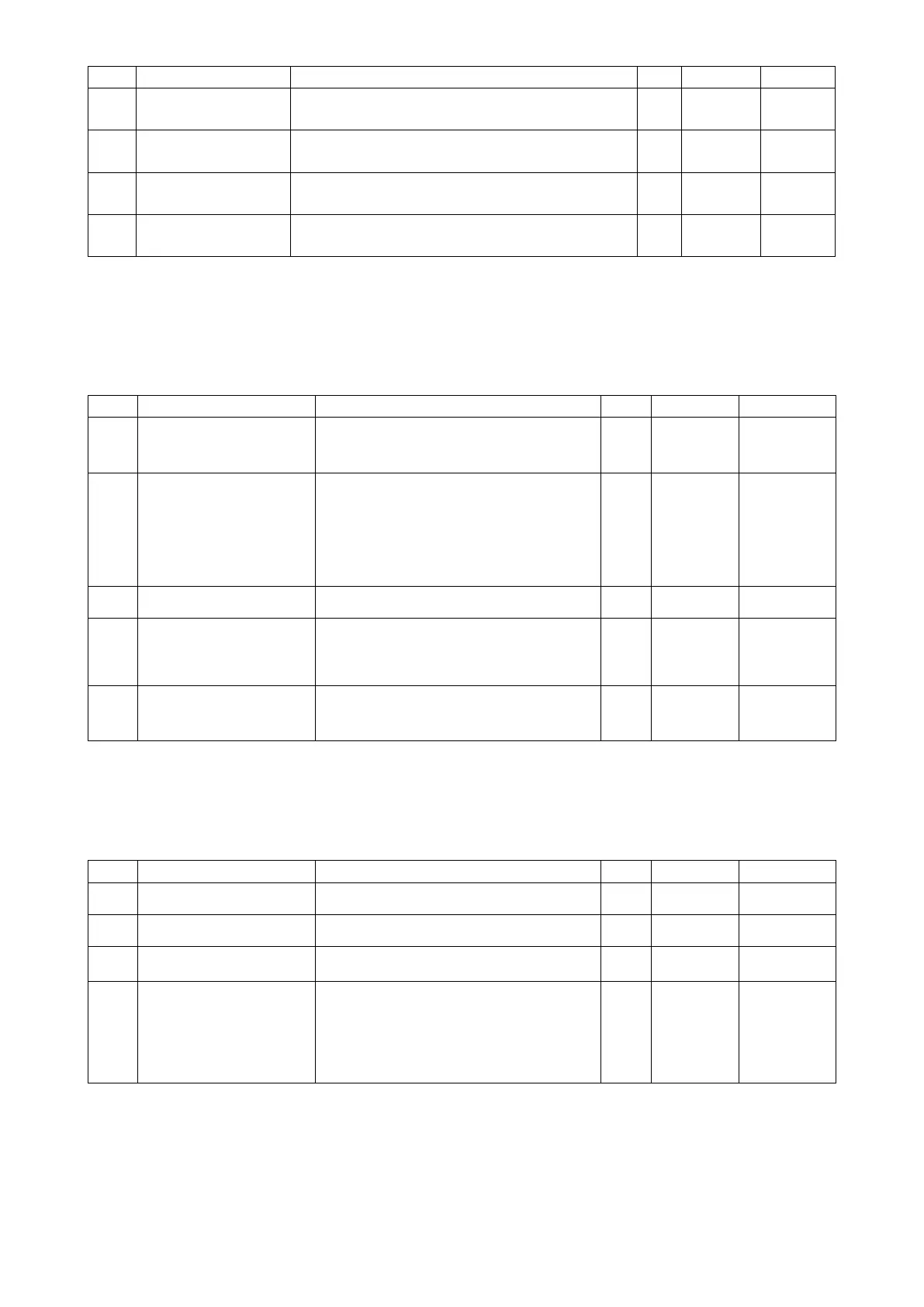

No. Item Description Level Setting range Default

N01

Main software version Main software version is displayed with this function

setting item.

U

N02

Panel software version Panel software version is displayed with this function

setting item.

U

N14 ST motor software version Version of the stepping motor control software is dis-

played with this function setting item.

U

N15 Number of stitches to stop the

grease counter

The number of stitches sewn is monitored in order to

notify the operator of the timing of replenishing grease.

Unit: (× 100,000 stitches)

When the grease counter value reaches 800,000,000

stitches, the grease shortage warning "E220" occurs.

When the grease counter value reaches 900,000,000

stitches, the grease shortage error "E221" occurs.

* The grease counter is cleared to "0" (zero).

S

No. Item Description Level Setting range Default

P167 2nd electric current value for

thread clamp (ON duty)

“ON duty” is set in order to determine the 2nd electric current

value of the thread clamp * Refer to the explanation of operation

of the thread clamp solenoid in the Engineer's Manual for details.

U 0-100 69

*

P168 Back-tack solenoid ON

parameter

Back-tack solenoid ON parameter

* Refer to the explanation of operation of the back-tack solenoid

in the Engineer's Manual for details.

S 1-200 25

*

P169 Back-tack solenoid ON

parameter

Back-tack solenoid ON parameter

* Refer to the explanation of operation of the back-tack solenoid

in the Engineer's Manual for details.

S 1-200 40

*

P170 Back-tack solenoid OFF

parameter

Back-tack solenoid OFF parameter

* Refer to the explanation of operation of the back-tack solenoid

in the Engineer's Manual for details.

S 1-200 10

*

Do not change the set values with asterisk (*) mark as they are functions for maintenance. If the standard set value set at the time

of delivery is changed, it is in danger of causing the machine to be broken or the performance to be deteriorated. If it is necessary to

change the set value, please purchase the Engineer’s Manual and follow the instructions.

③

At the time of operating the sewing machine

Guidance on the production support

– 41 –

Loading...

Loading...