– 20 –

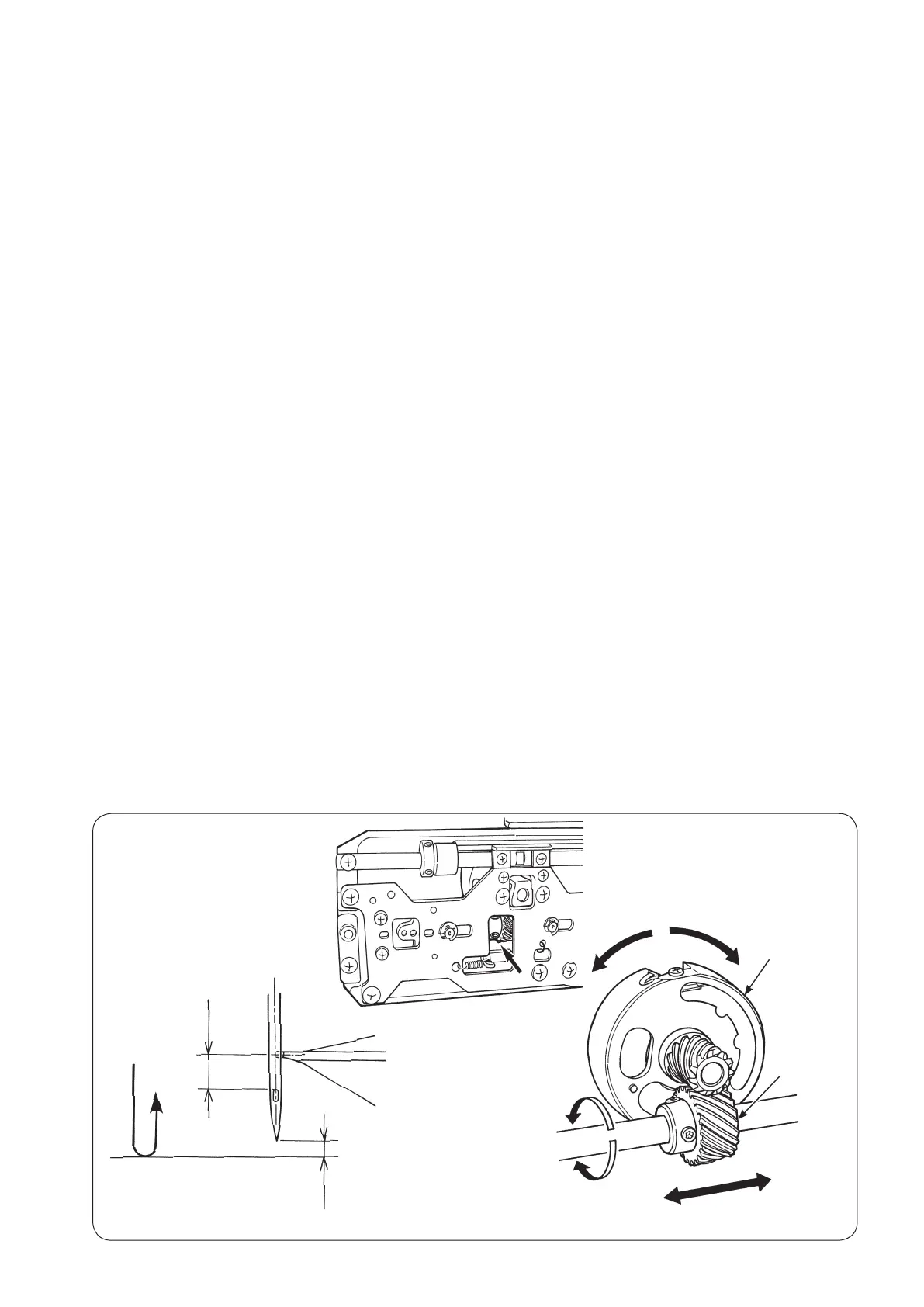

6-8 Timing between the needle and the hook

○

Removethethroatplate,thebottomcoverA/Bandthebottomcoverofthefreearm.

Method for checking

1.Checktobesurethattheneedleentrypointandneedlebarheightarecorrect.

2.Selectthestraightstitch.Selecttherightneedlepositionbyusingthezigzagwidthadjustingdial.

(The needle entry point is shifted to the rightmost side.)

3.Now,turnthehandwheelbyhandtobringtheneedlebartoitslowestdeadpoint.

4.Turnthehandwheelfurthertograduallylifttheneedlebaruntilpoint

C

where the needle center is aligned

withthetipofbladepointofthehookisreached.

5.Atthistime,checktobesurethatthedistance

D

fromthetipofbladepointofthehooktotheupperend

oftheneedleeyeis3.1to3.3mm.Ifthisdistanceisnotcorrectlyprovided,carryoutthefollowingadjust-

ment.

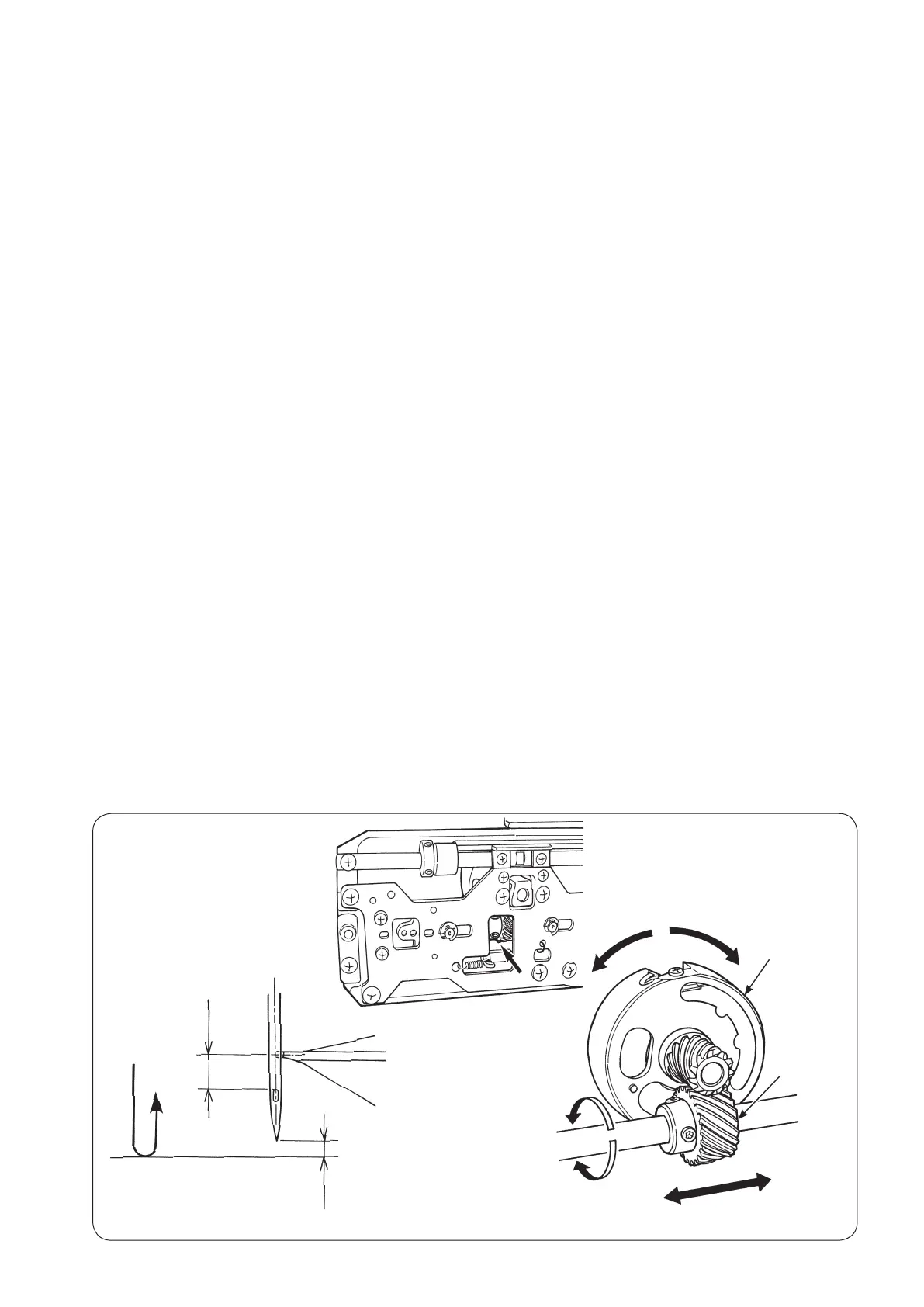

Adjustmentprocedure

1.Loosenthesetscrewinthehookdrivinggearwhichisnotvisiblefromundersideofthesewingmachine

whentheneedlecenteralignswiththetipofbladepointofthehook.

2. Select the straight stitch and the right needle position. Move the hook driving gear in the rotational direc-

tiontoadjustdistance

D

of3.1to3.3mmisprovidedbetweenthetipofbladepointofthehookandthe

upperendoftheneedleeyewhentheneedlebarisliftedby1.6mmfromthelowestdeadpointbyturning

thehandwheelbyhand.

Atthistime,thebacklashbetweenthehookdrivinggearandthegearonthehooksidemaychangede-

pendingonthelocationofthehookdrivinggearonthehookdrivingshaft.Adjustmentshould,therefore,

becarriedoutwiththevisiblesetscrewtemporarilytightened,whilecarefullyobservingthehookdriving

gearinboththerotationaldirectionandaxialdirection.Adjustthebacklashto0.2to0.7mmontheperiph-

ery of the rotating hook.

3.Afterconrmingthetimingbetweentheneedleandhookiscorrectlyadjusted,securelytightenbothset-

screws.

(Caution) After adjustment of the hook, the hook race surface and the bobbin case holder may be stained

with dirt, oil or grease. Wipe them off with alcohol where necessary.

If those parts are left stained, chattering or thread slip-off noise of the bobbin case holder can

occur.

Distance D : 3.1 to 3.3 mm

1.6 mm

C

Backlash on the periphery of the

rotating hook 0.2 to 0.7 mm

Rotating

hook

Hook

driving

gear

Backlash

Larger

Smaller

Loading...

Loading...