9.

EXPENDABLE

PARTS

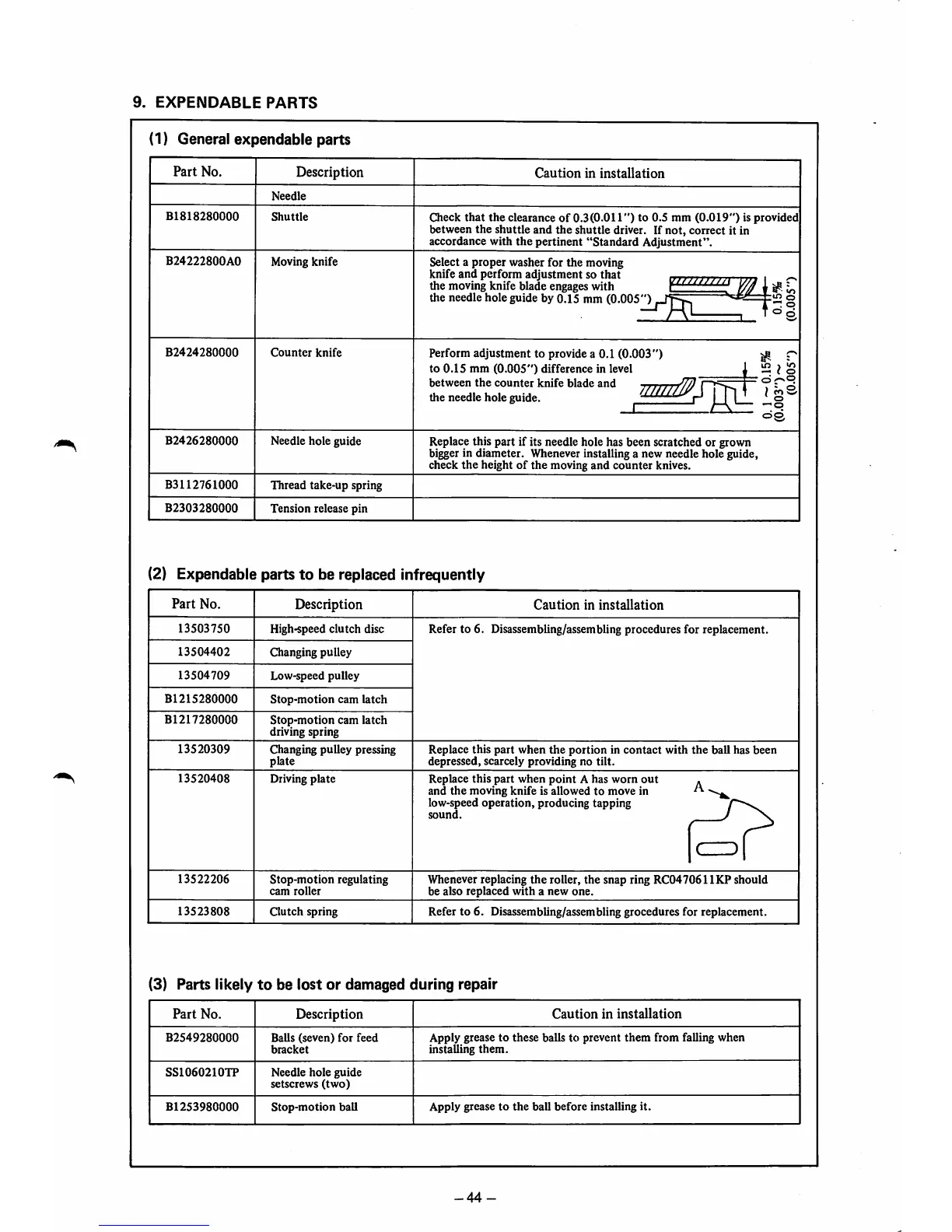

(1) General expendable parts

Part

No.

Description

Needle

B1818280000

Shuttle

B24222800A0

Moving

knife

B2424280000

Counter

knife

B2426280000

Needle

hole

guide

B3112761000

Thread

take-up

spring

B2303280000

Tension release

pin

Caution

in

installation

Check

that

the

clearance

of

0.3(0.011")

to 0.5 mm

(0.019")

is provided

between the shuttle

and

the

shuttle driver. If

not,

correct it in

accordance with the pertinent "Standard Adjustment".

Select a proper washer for the moving

knife

and

perform adjustment so

that

the moving knife blade engages with

the needle hole guide by 0.15 mm

(0.005")

rs^

o

" o

°

6.

Perform adjustment to provide a 0.1

(0.003")

to

0.15

mm

(0.005")

difference

in level

between

the

counter

knife

blade

and

7

the needle

hole

guide.

m >

lo

—

to

o

) fo S

o

" o

oci

Replace this part if its needle hole has been scratched or grown

bigger in diameter. Whenever installing a new needle hole guide,

check

the

height

of

the

moving and counter knives.

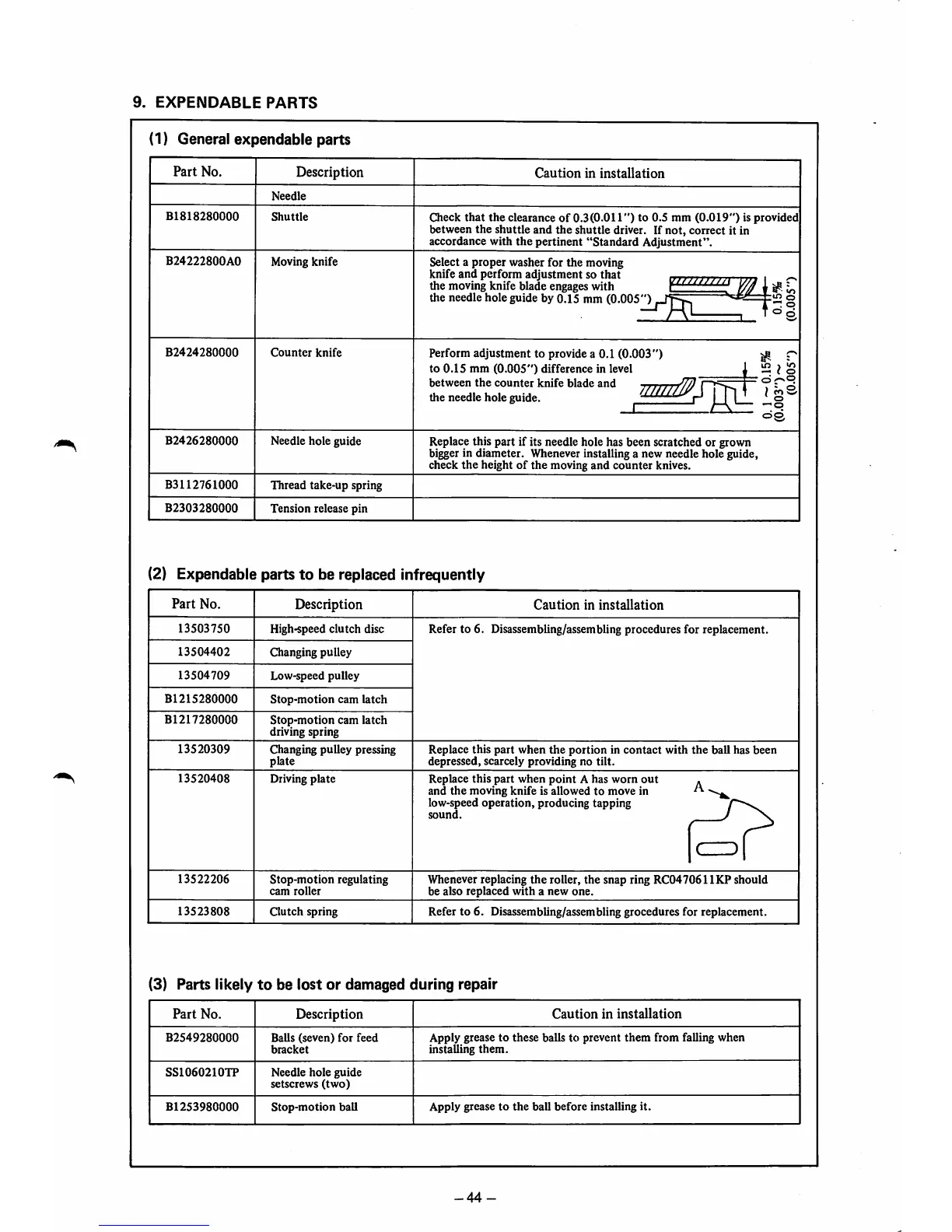

(2) Expendable parts to be replaced infrequently

Part

No.

Description

Caution

in

installation

13503750

High-speed

clutch

disc Refer to 6. Disassembling/assembling procedures for replacement.

13504402

Changing

pulley

13504709

Low-speed pulley

B1215280000

Stop-motion

cam

latch

B1217280000

Stop-motion

cam

latch

driving spring

13520309

(Changing

pulley

pressing

plate

Replace this part when the portion in

contact

with

the

ball has been

depressed, scarcely providing no tilt.

13520408

Driving

plate

Replace

this

part

when

point

A has

worn

out

and

the

moving

knife

is allowed

to

move

in

low-speed

operation,

producing tapping

sound.

f )|

13522206

Stop-motion

regulating

cam

roller

Whenever replacing

the

roller,

the

snap ring

RC0470611KP

should

be also

replaced

with

a

new

one.

13523808

Qutch

spring Refer to 6. Disassembling/assembling grocedures for replacement.

(3) Parts likely

to

be lost or damaged during repair

Part

No.

Description

Caution

in

installation

B2549280000

Balls

(seven)

for

feed

bracket

Apply

grease to

these

balls to

prevent

them

from

falling

when

installing

them.

SS1060210TP

Needle

hole

guide

setscrews

(two)

B1253980000

Stop-motion

ball

Apply

grease

to

the

ball

before

installing

it.

44-

Loading...

Loading...