– 52 –

3. INSTALLATION OF THE OPTIONAL PARTS

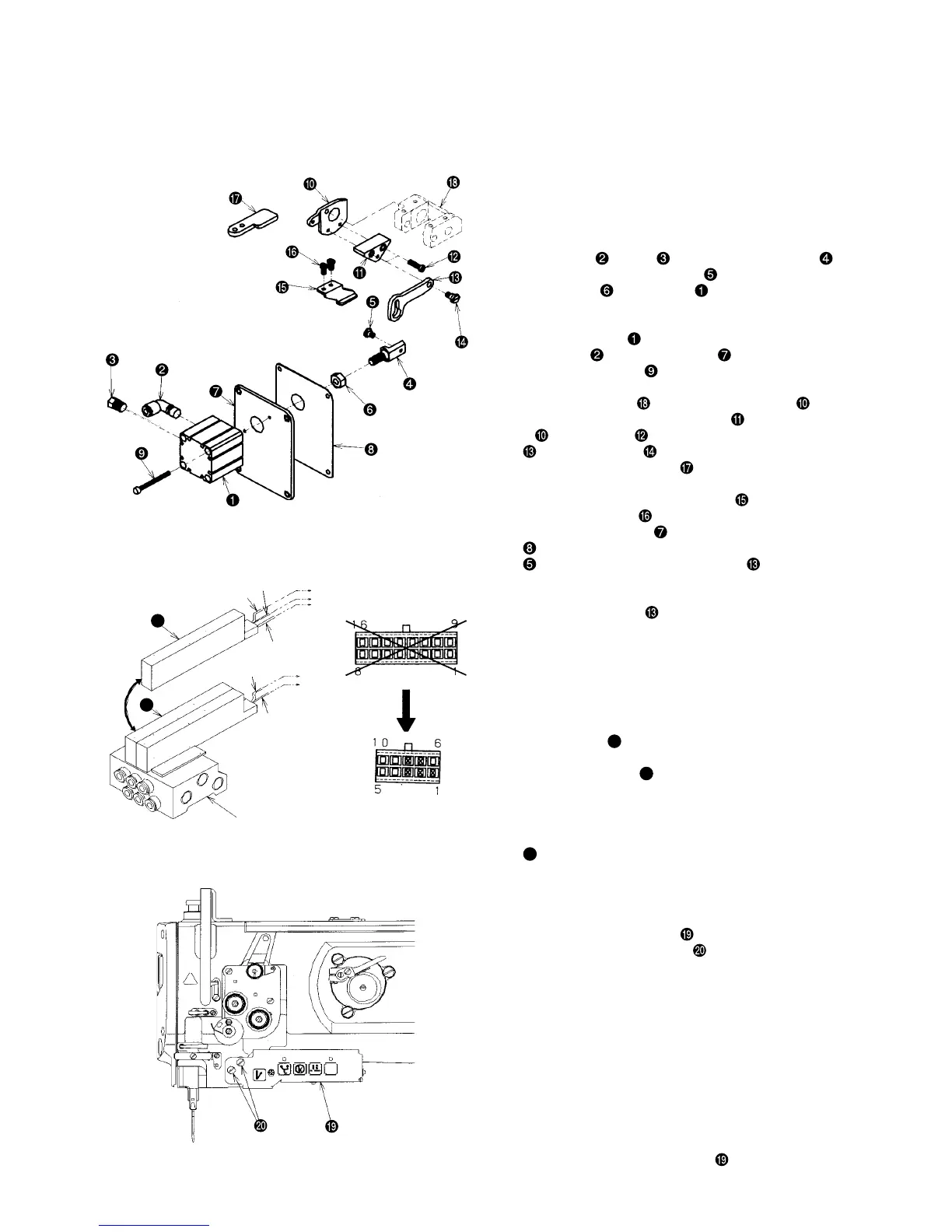

(1) DL device (For the machine with thread trimmer only)

o Installing DL device (List A)

Part No. of DL22 Kit C for installation after mechanical

setup: 40025683

* Please order from us with the aforementioned part No.

(Applicable models: LU-1510N-7, LU-1511N-7, LU-1560N-

7, LU-1561N-7)

1. Remove window plate C and window plate packing C lo-

cated on the anti-operator’s side of the machine arm.

2. Attach elbow

, muffler , cylinder connecting screw ,

alternate vertical link hinge screw and cylinder connect-

ing screw nut to jig cylinder . (Assemble so that the

distance from the edge of cylinder connecting screw to the

end of cylinder shaft is 10 mm.)

3. Attach jig cylinder

which has been assembled at the

above step

. to window plate F and tighten it with

jig cylinder setscrew .

4. Remove the top feed stopper plate A attached to alternate

vertical change base

and install stopper plate B .

5. Tighten alternate vertical link spacer to stopper plate

B with setscrew and tighten alternate vertical link

with hinge screw .

6. Attach top feed stopper plate in the kit instead of the top

feed stopper plate attached to the machine arm.

7. Tighten alternate vertical link support

to the machine

arm with setscrews .

8. Install window plate F and window plate packing E

. At this time, enter alternate vertical link hinge screw

to the hole of alternate vertical link and attach it

to the machine arm.

(When the alternate vertical dial is set to the maximum,

alternate vertical link

comes out to the front and it is

easy to enter the screw in the hole.)

9. Change the automatic reverse feed device attached to

window plate C to window plate D.

10. Attach the window plate D and window plate packing B

with the window plate setscrew.

11. Re-adjust the respective timing adjustment referring to

this manual.

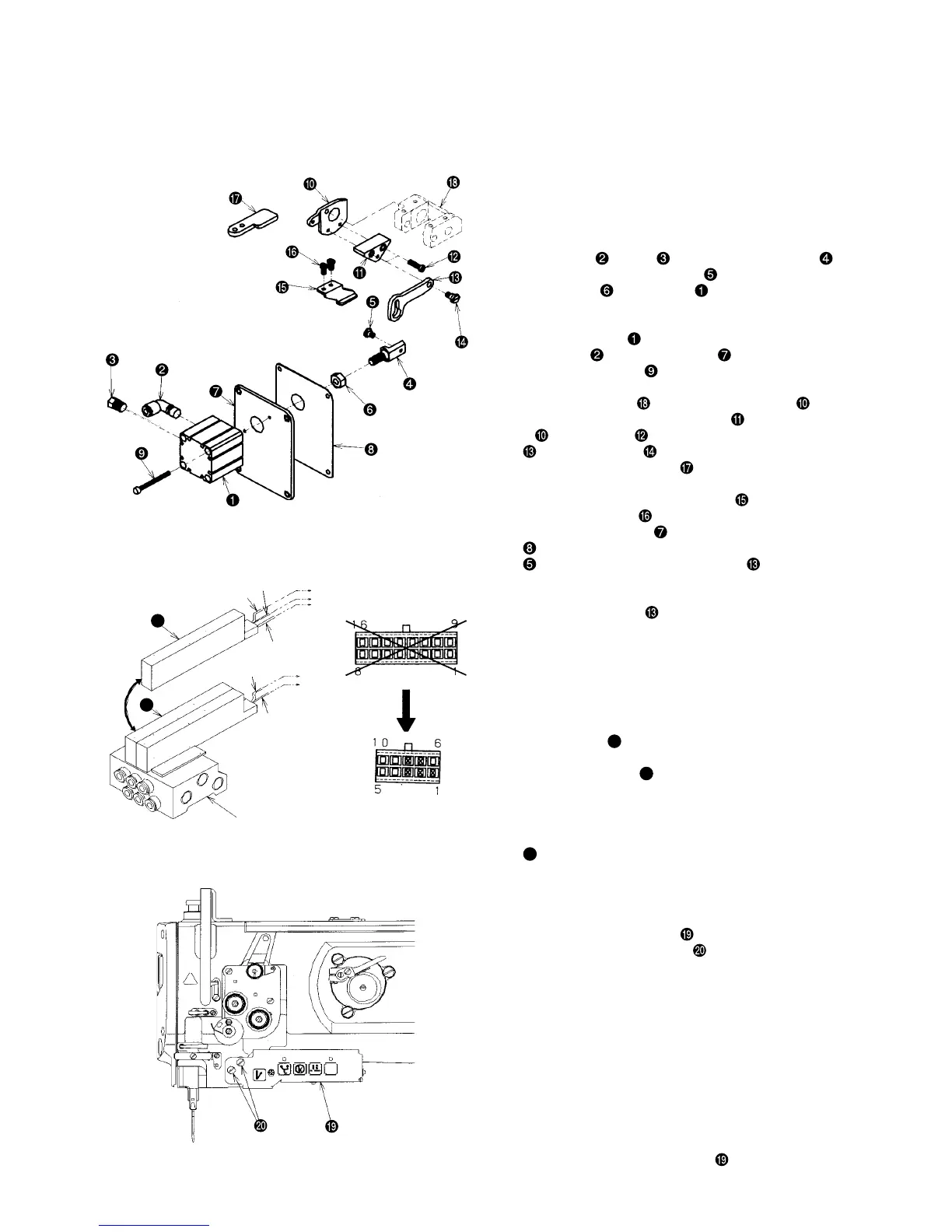

12. Solenoid valve

a

is attached to solenoid valve B (asm.)

(Part No.: GAKA2301BA0) presently used. Replace this valve

with solenoid valve D

A

.

(At that time, remove all pins from the 16-pin connector. This

treatment is needed when replacing a 16-pin connector with

a 10-pin connector.)

13. Caulk the female terminal at the cord tip of solenoid valve D

A

that has been replaced as per 12. above.

14. Insert the female terminal in the housing (10-pin

connector) (CN20) of the kit interior. Confirm the

inserting position before taking actions.

15. Remove the BT switch that is attached to the arm, and

attach 5-operation switch

of the kit interior to the

arm by means of setscrews

. At that time, remove

the BT switch pin from the 12-pin connector located

on sewing machine side.

16. Make a connection between the 16-pin connector of the 5-

operation switch and that of the relay cord connected to SC-

510.

17. Make a connection between the 12-pin connector attached

to the arm and that of the relay cord connected to SC-510.

18. Make a connection between the 10-pin connector of the

solenoid valve B (asm.) and that of the 5-operation switch.

19. Turn ON the power supply of SC-510.

20. Check whether the amount of alternate vertical movement

becomes maximum when the DL switch (second button

from left of the 5-operation switch

) is pressed.

o Installing the pneumatic components (List B)

o Installing the 5-operation switch (List C)

Red

Black

Solenoid valve B (asm.)

Red

CN20-8

CN20-3

CN20-1

a

A

CN20-7

CN20-2

CN20

Black

White

Loading...

Loading...