Disassembly/Inspection and Service

8319 690 01 Rev. -- KohlerEngines.com

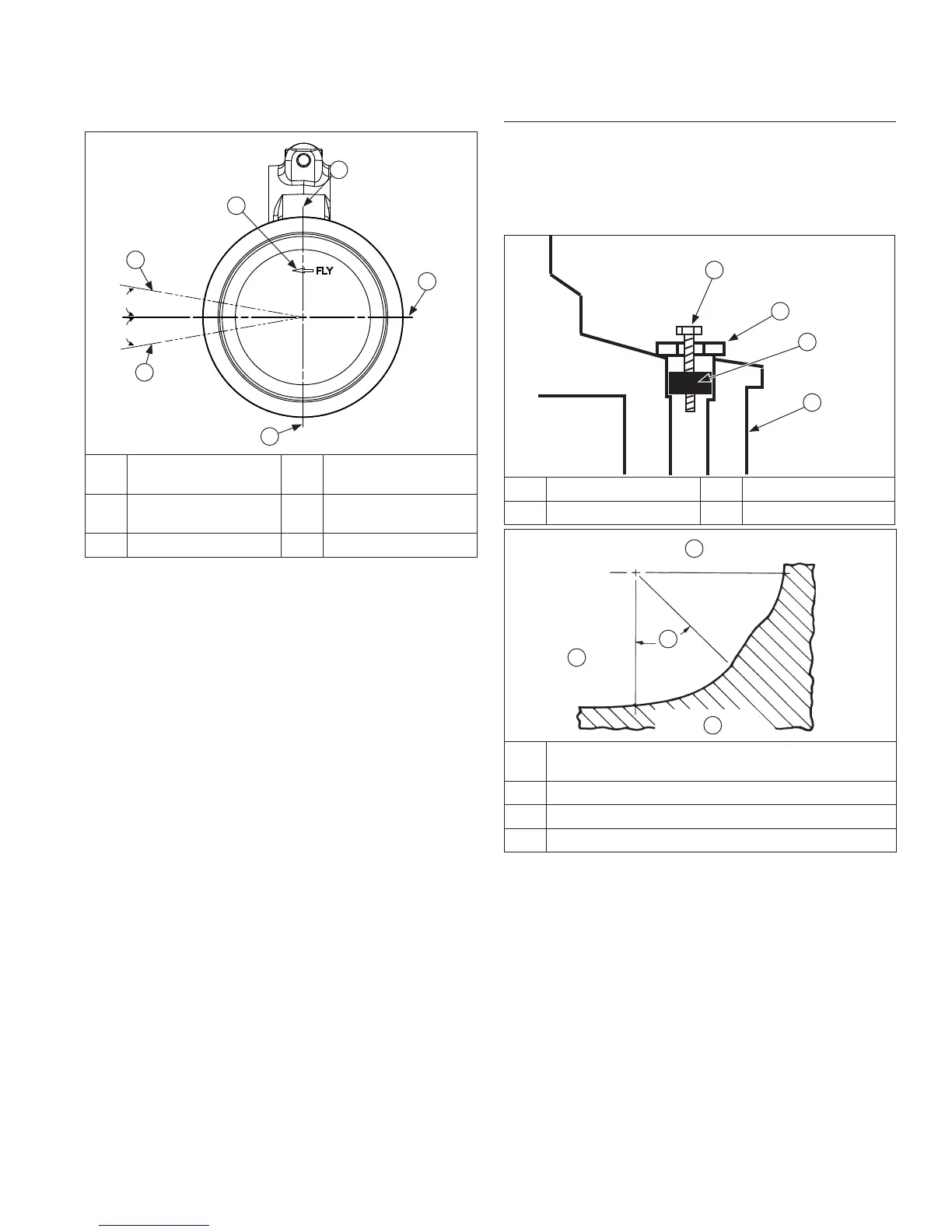

Install New Piston Rings

Piston Ring Orientation

10°

10°

F

A

B

C

D

E

A

Top Oil Ring Rail

Gap

B

Bottom Oil Ring Rail

Gap

C

Intermediate Ring

Gap

D

Oil Ring Expander

Gap

E Top Ring Gap F FLY Stamp

NOTE: Rings must be installed correctly. Ring

installation instructions are usually included with

new ring sets. Follow instructions carefully. Use

a piston ring expander to install rings. Install

bottom (oil control) ring fi rst and top

compression ring last.

To install new piston rings, proceed as follows:

1. Oil control ring (bottom groove): Install expander and

then rails. Make sure ends of expander are not

overlapped.

2. Middle compression ring (center groove): Install

center ring using a piston ring installation tool. Make

sure identifi cation mark is up or colored dye stripe (if

contained), is to left of end gap.

3. Top compression ring (top groove): Install top ring

using a piston ring expander. Make sure

identifi cation mark is up or colored dye stripe (if

contained), is to left of end gap.

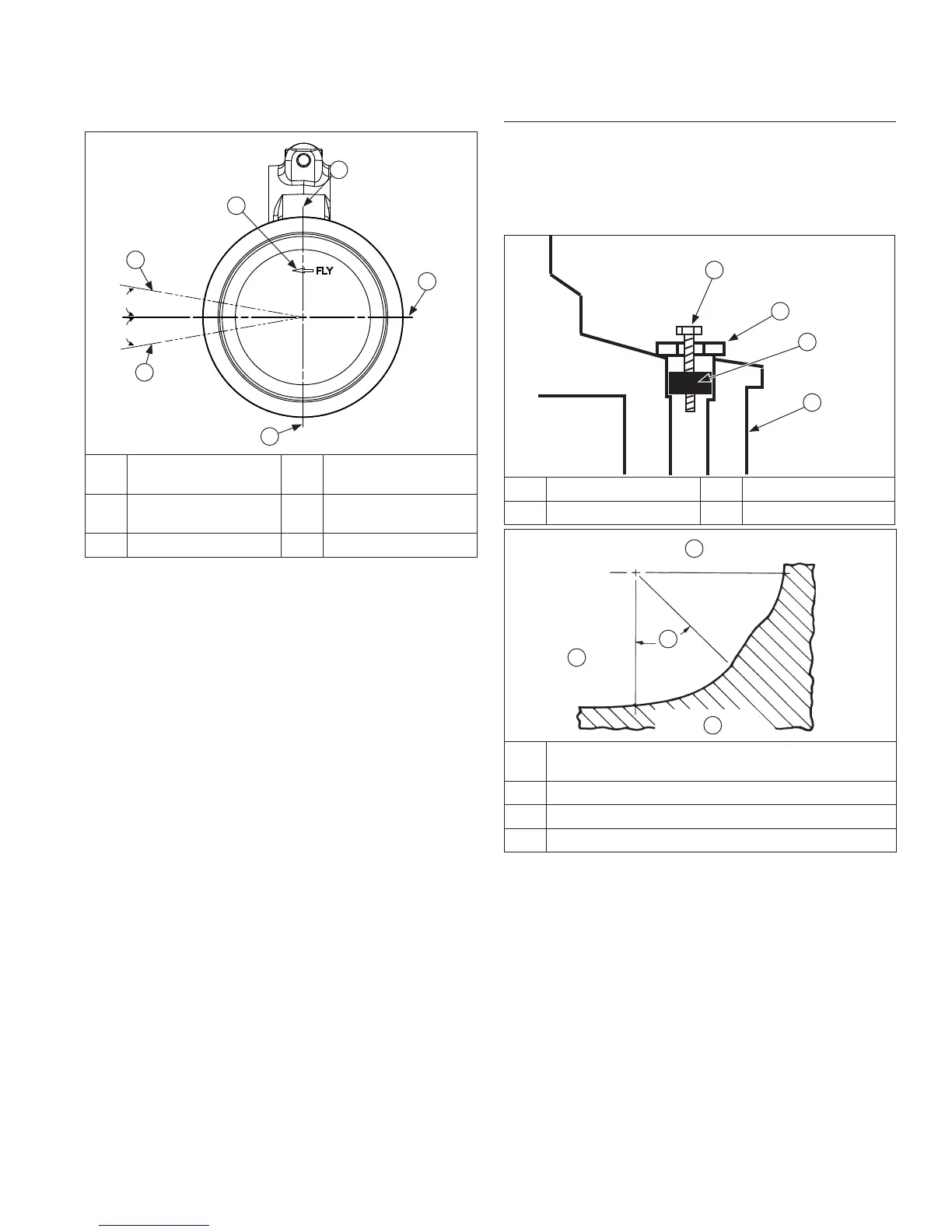

Remove Crankshaft

NOTE: If crankpin is reground, visually check to ensure

that fi llet blends smoothly with crankpin surface.

Carefully pull crankshaft from crankcase. Note thrust

washers and shims if used.

Inspection and Service

Crankshaft Components and Details

A Self-Tapping Screw B Flat Washer

C Plug D Crankshaft

A

B

C

D

E

Fillet Must Blend Smoothly with Bearing Journal

Surface

F High Point from Fillet Intersections

G 45° Minimum

H This Fillet Area Must Be Completely Smooth

E

G

F

H

Inspect gear teeth of crankshaft. If teeth are badly worn,

chipped, or some are missing, replacement of crankshaft

will be necessary.

Inspect crankshaft bearing surfaces for scoring,

grooving, etc. Measure running clearance between

crankshaft journals and their respective bearing bores.

Use an inside micrometer or telescoping gauge to

measure inside diameter of both bearing bores in vertical

and horizontal planes. Use an outside micrometer to

measure outside diameter of crankshaft main bearing

journals. Subtract journal diameters from their respective

bore diameters to get running clearances. Check results

against values in Specifi cations. If running clearances

are within specifi cation, and there is no evidence of

scoring, grooving, etc., no further reconditioning is

necessary. If bearing surfaces are worn or damaged,

crankcase and/or oil pan will need to be replaced.

Loading...

Loading...