METHOD FOR CHECKING ALL TIGHTENING POINTS OF ENGINE INTAKE PIPE

CLAMPS

Ask your Komatsu distributor for

checking the tightening of the clamps between the air cleaner - turbocharger -

aftercooler - engine.

METHOD FOR CHECKING AND REPLACING ALTERNATOR BELT

• Special tools are required for the replacement of the belt. Ask your Komatsu distributor to perform this work.

• Since the auto-tensioner is installed, tension adjustment is not required.

If alternator drive belt shows the following conditions, it must be

replaced. Ask your Komatsu distributor to replace it.

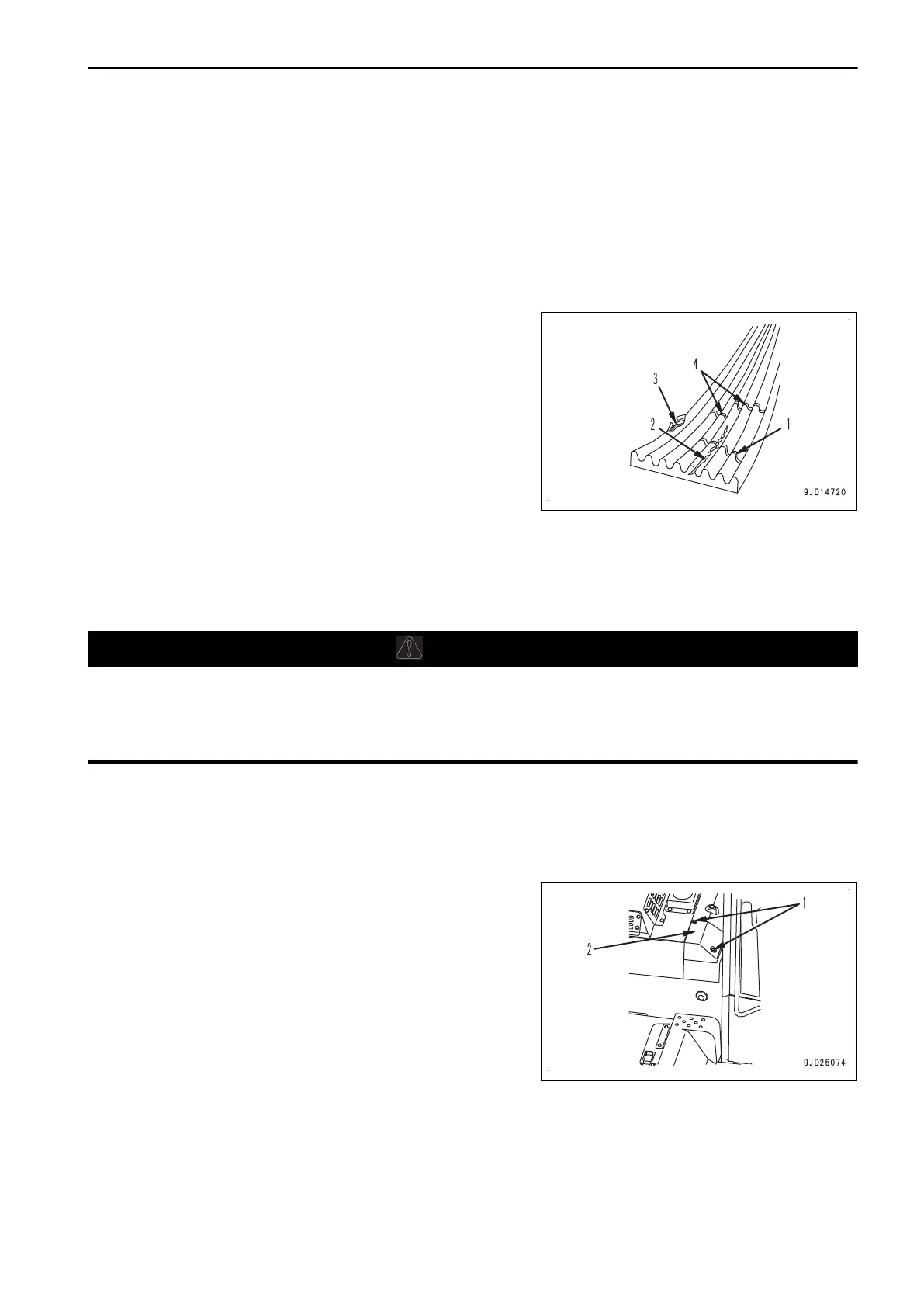

• When vertical flaw (2) that crosses horizontal flaw (1) is

found.

• When a part of the belt has tears (3).

• You do not need to replace the belt when it has only hori-

zontal flaw (4).

EVERY 2000 HOURS MAINTENANCE

Maintenance for every 50, 100, 250, 500, and 1000 hours service should be performed at the same time.

METHOD FOR CHANGING OIL IN HYDRAULIC TANK, CLEANING HYDRAULIC

TANK STRAINER

WARNING

• Immediately after the engine is

stopped, its parts and oil are still very hot and may cause burn in-

jury. Wait for the temperature to go down, and then start the work.

• When removing the oil filler cap, the oil may spurt out. Turn it slowly to release the internal pres-

sure, then remove it carefully.

Refill capacity: 92 ℓ

Items to be prepared

• Container to catch the drained oil

1.

Lower the bucket to the ground with its bottom level, apply the parking brake, then stop the engine.

2.

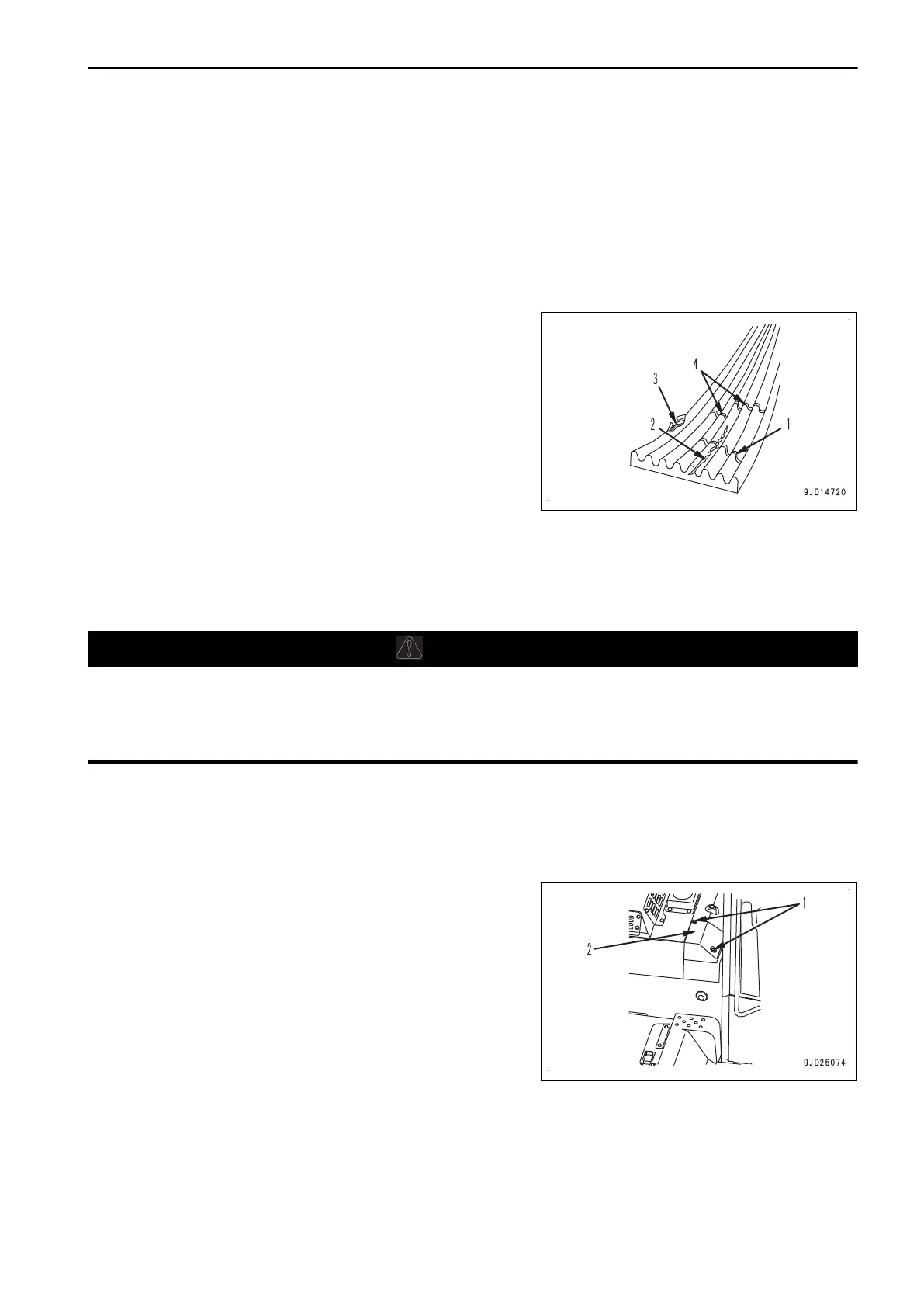

Remove the bolts (1) (2 pieces) and remove the cover (2).

MAINTENANCE MAINTENANCE PROCEDURE

4-63

Loading...

Loading...