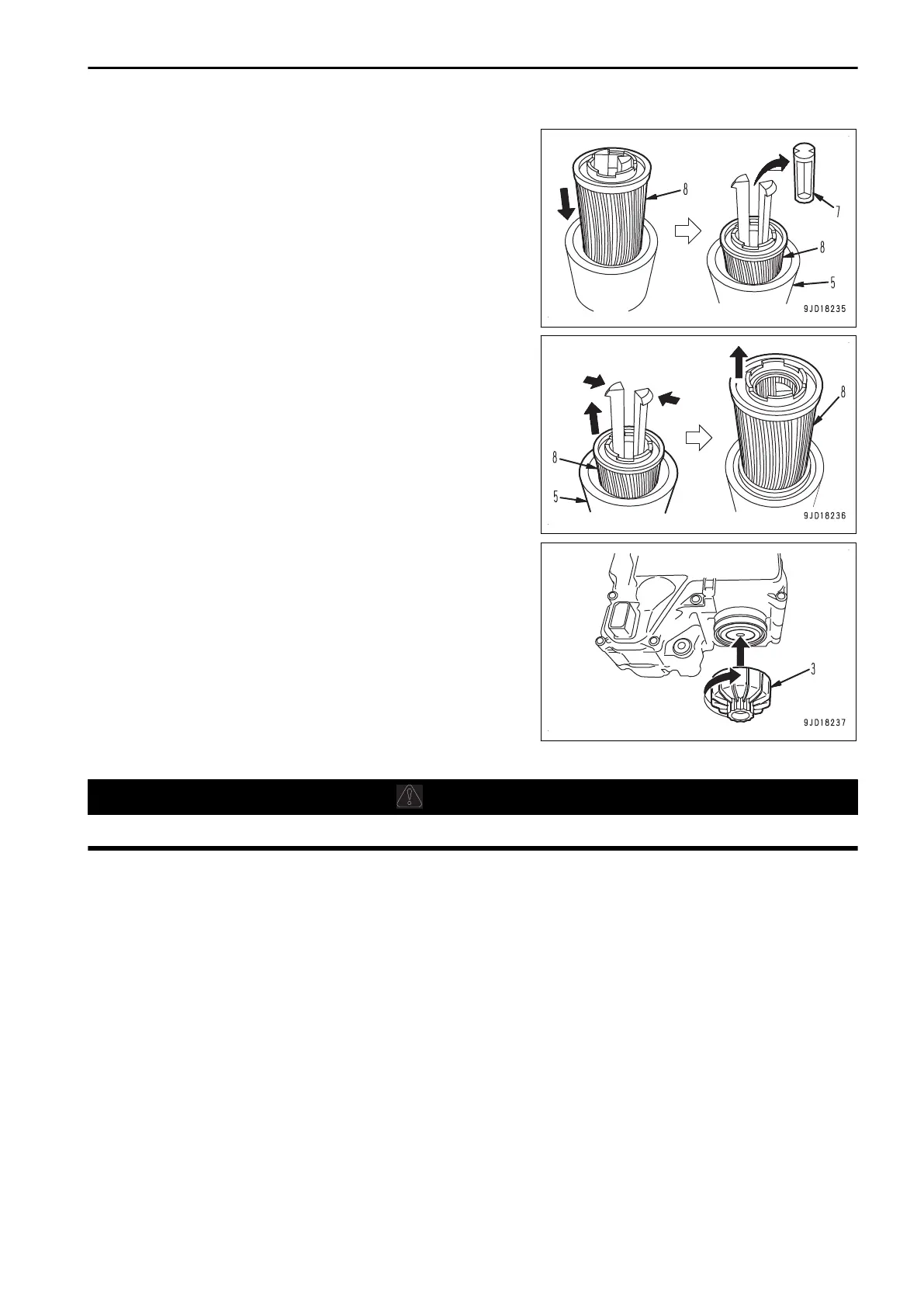

8.

Slide filter (8) down, and

remove spacer (7) from filter re-

moval tool (5).

9.

Pull filter (8) up while pushing in the tip of filter removal

tool (5), and remove it.

10.

Return the removed spacer (7) to filter removal tool (5),

and keep them.

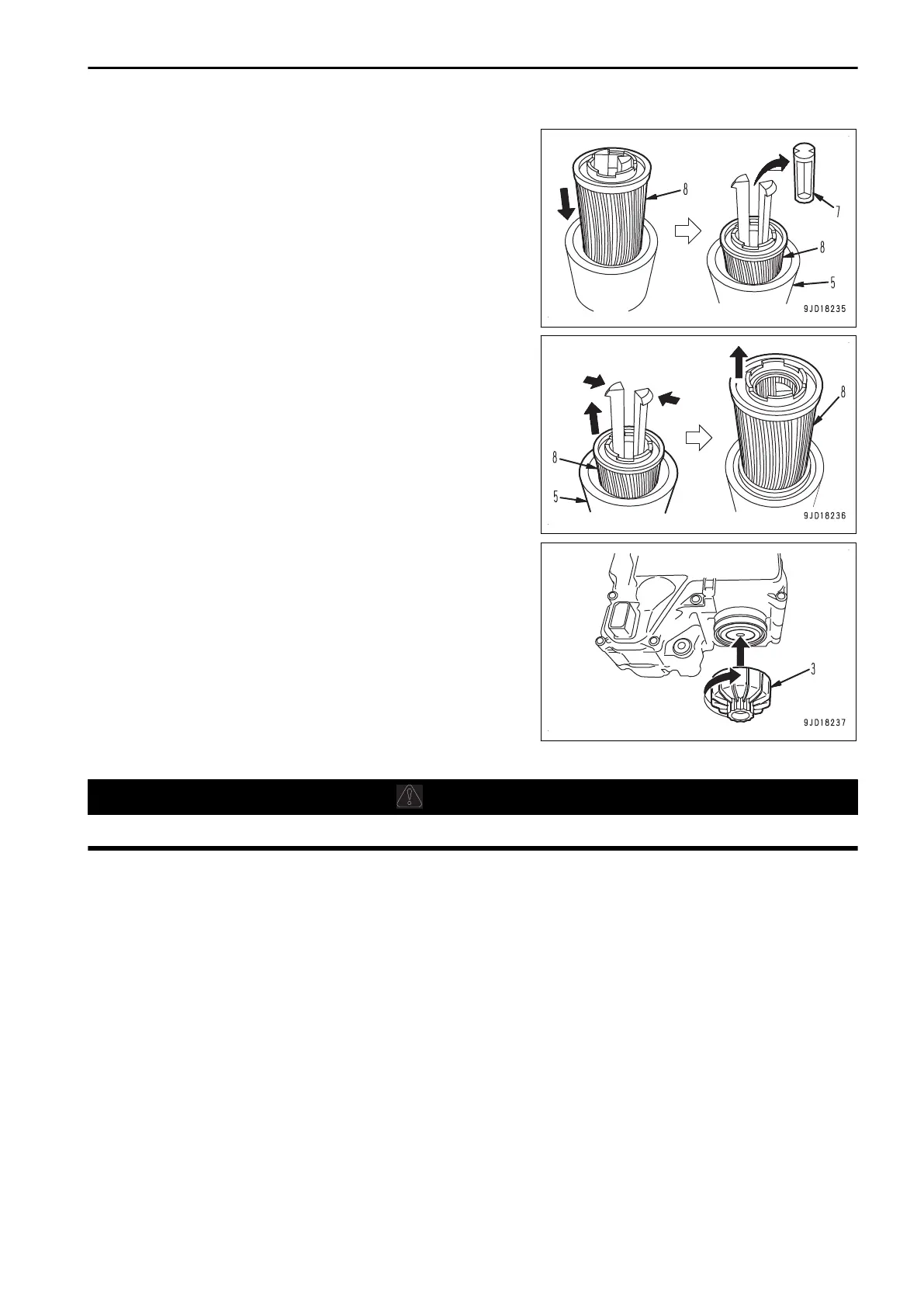

11.

Insert a new filter and a new equalizing element into the

bottom of DEF pump, and lightly tighten them with hand.

12.

Tighten filter cap (3).

Tightening torque: 20 to 25 Nm {2.0 to 2.5 kgm}

13.

Install cover (2) with bolts (1) (6 pieces).

METHOD FOR REPLACING DEF TANK BREATHER ELEMENT

WARNING

Do not replace the element immediately after engine is stopped.

NOTICE

• Komatsu recommends using Komatsu genuine parts for replacement parts.

• If the machine

is operated without DEF tank breather element attached, or with the element other

than Komatsu genuine parts, foreign materials may enter into DEF pump and DEF injector which

will cause failure of the machine. Never operate the machine without DEF tank breather element at-

tached, nor use the element other than Komatsu genuine parts.

• Do not flush DEF tank breather element. Flushing or regenerating of it will degrade the performance

of element, and will cause the breakage of DEF tank. Never reuse the DEF element.

• Always stop the engine and clean around DEF tank before replacing.

• After the engine is stopped, DEF system devices automatically purge DEF in DEF injector and DEF

pump and return it to DEF tank to prevent malfunction of the devices caused by freezing of DEF or

deposition of urea.

After the engine is stopped, the devices are operated for a few minutes. Replace the element after

DEF system devices stop.

• Improper assembly of DEF tank breather element may cause leakage of DEF. Replace the element in

the correct procedure.

MAINTENANCE MAINTENANCE PROCEDURE

4-79

Loading...

Loading...