Paragraphs 15-17

KUBOTA

Fig. 36—Install speciai

mounting plate (1) to retain

ball nut and thrust bearings

while tightening worm shaft

tocknut See Fig. 36A.

Fig, 38—As a finai assembly check, measure

torque required to start rotation of worm shaft

Torque should not exceed 1.7 N-m (15 In.-lbs.)

special plate and install top cover.

Tighten retaining screws to a torque of

40-55 N-m (30-40 ft.-lbs.). Align match

marks and install pitman arm onto sec-

tor shaft. Tighten retaining nut to a tor-

que of 120-155 N-m (90-115 ft.-lbs.).

Check backlash between sector gear

and ball nut using a dial indicator as

shown in Fig. 37. Turn adjusting screw

(5-Fig. 28) as required to obtain recom-

mended backlash of 0.1-0.4 mm

(0.004-0.016 inch). To check for proper

final assembly of steering gear, use a

torque wrench as shown in Fig. 38 to

measure torque required to start rota-

tion of worm shaft. Torque should be

less than 1.7 N-m (15 in.-lbs.). If

measured torque exceeds 1.8 N-m (16

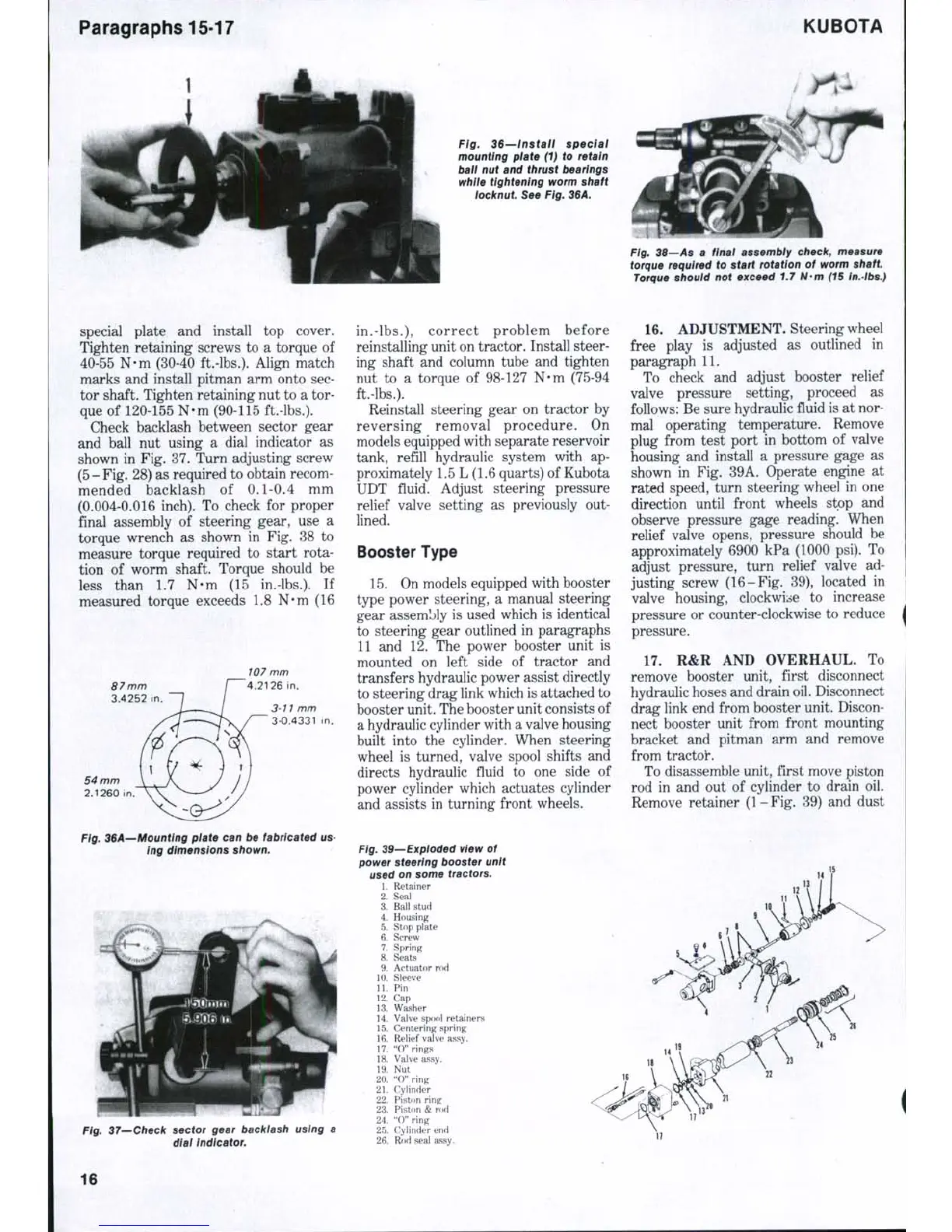

Ftg. 36A—Mounting plate can be fabricated us-

ing dimensions shown.

37—Check sector gear backlash using a

dtat Indicator.

in.-lbs.),

correct problem before

reinstalling unit on tractor. Install steer-

ing shaft and column tube and tighten

nut to a torque of 98-127 N-m (75-94

ft.-lbs.).

Reinstall steering gear on tractor by

reversing removal procedure. On

models equipped with separate reservoir

tank, refill hydraulic system with ap-

proximately 1.5 L (1.6 quarts) of Kubota

UDT fluid. Adjust steering pressure

relief valve setting as previously out-

lined.

Booster Type

15.

On models equipped with booster

type power steering, a manual steering

gear assembly is used which is identical

to steering gear outlined in paragraphs

11 and 12. The power booster unit is

mounted on left side of tractor and

transfers hydraulic power assist directly

to steering drag link which is attached to

booster unit. The booster unit consists of

a hydraulic cylinder with a valve housing

built into the cylinder. When steering

wheel is turned, valve spool shifts and

directs hydraulic fluid to one side of

power cylinder which actuates cylinder

and assists in turning front wheels.

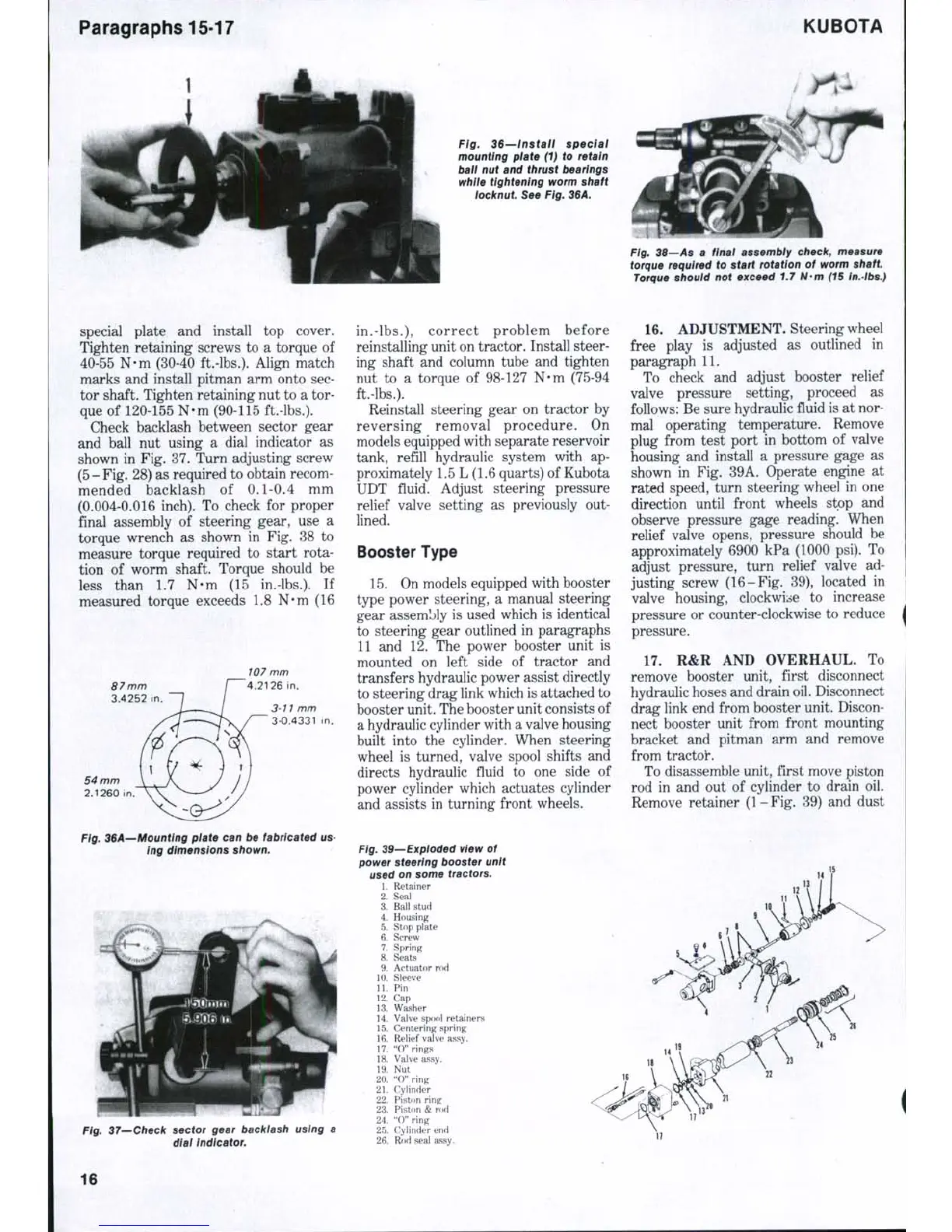

Fig. 39—Exploded view of

power steering booster unit

used on some tractors.

1.

Retainer

2.

Seal

3.

Ball stud

4.

Housing

5.

Stop plate

6. Screw

7.

Spring

8. Seats

9. Actuator rod

10.

Sleeve

11.

Pin

12.

Cap

13.

Washer

14.

Valve spool retainers

15.

Centering spring

16.

Reliefvalve assy.

17.

"O" rings

18.

Valve assy.

19.

Nut

20.

"0" ring

. 21. Cylinder

22.

Piston ring

23.

Piston & rod

24.

"0" ring

25.

Cylinder end

26.

Rod seal assy.

16.

ADJUSTMENT. Steering wheel

free play is adjusted as outlined in

paragraph 11.

To check and adjust booster relief

valve pressure setting, proceed as

follows: Be sure hydraulic fluid is at nor-

mal operating temperature. Remove

plug from test port in bottom of valve

housing and install a pressure gage as

shown in Fig. 39A. Operate engine at

rated speed, turn steering wheel in one

direction until front wheels stop and

observe pressure gage reading. When

relief valve opens, pressure should be

approximately 6900 kPa (1000 psi). To

adjust pressure, turn relief valve ad-

justing screw (16-Fig. 39), located in

valve housing, clockwise to increase

pressure or counter-clockwise to reduce

pressure.

17.

R&R AND OVERHAUL. To

remove booster unit, first disconnect

hydraulic hoses and drain oil. Disconnect

drag link end from booster unit. Discon-

nect booster unit from front mounting

bracket and pitman arm and remove

from tractor.

To disassemble unit, first move piston

rod in and out of cylinder to drain oil.

Remove retainer (1-Fig. 39) and dust

16

Loading...

Loading...