SHOP MANUAL

transmission housings, then remove

mounting stud nuts

and

separate hous-

ings.

When reconnecting tractor, tighten

housing mounting stud nuts

to a

torque

of 103-118

N-m

(76-86 ft.-lbs.), clutch

housing mounting bolts

to

78-90

N*m

(57-66 ft.-lbs.)

and

engine mounting

bolts

to a

torque

of

49-56

N-m

(36-41

ft.-lbs.)

Be

sure "0" rings

are

correctly

positioned when reinstalling hydraulic

pipes.

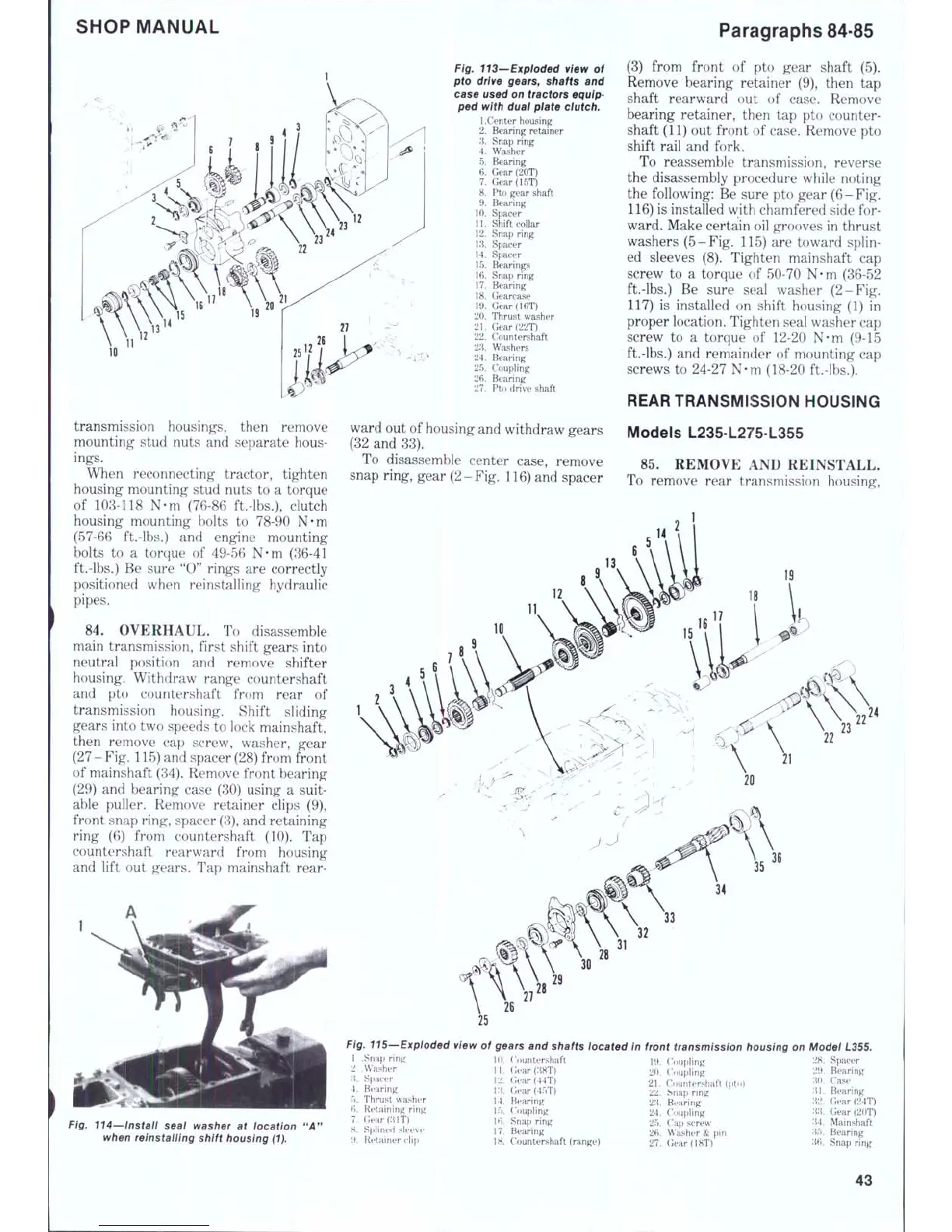

84.

OVERHAUL.

To

disassemble

main transmission, first shift gears into

neutral position

and

remove shifter

housing. Withdraw range countershaft

and

pto

countershaft from rear

of

transmission housing. Shift sliding

gears into two speeds

to

lock mainshaft,

then remove

cap

screw, washer, gear

(27

-

Fig.

115) and spacer (28) from front

of mainshaft (34). Remove front bearing

(29)

and

bearing case

(30)

using

a

suit-

able puller. Remove retainer clips

(9),

front snap ring, spacer

(3),

and retaining

ring

(6)

from countershaft

(10). Tap

countershaft rearward from housing

and lift

out

gears.

Tap

mainshaft rear-

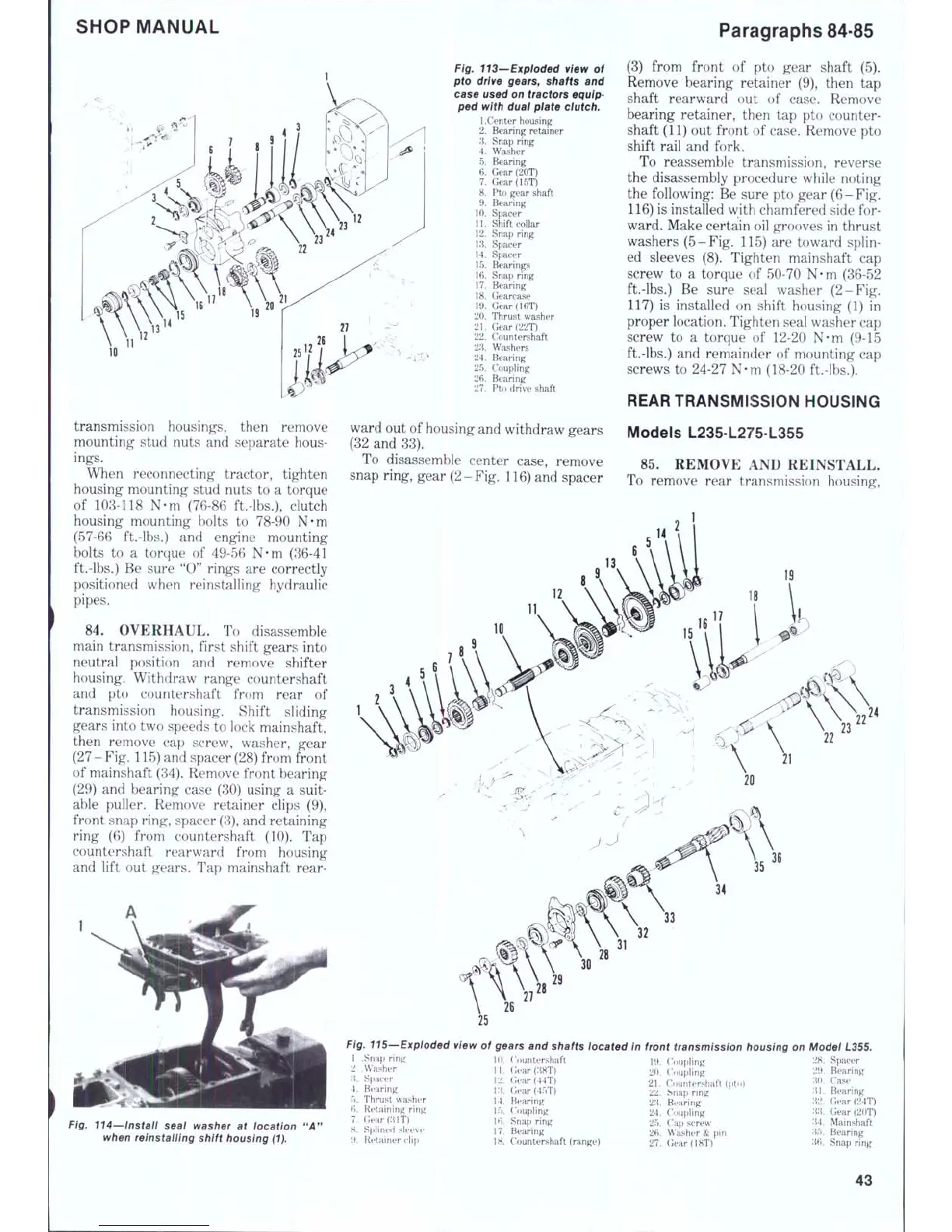

Fig. 113—Exploded view of

pto drive gears, shafts and

case used on tractors equip-

ped witfi dual plate clutch.

1

.Center housing

2.

Bearing retainer

3.

Snap ring

4.

Washer

5.

Bearing

6. Gear

(20T)

7.

Gear(15T)

8.

Pto

gear shaft

9. Bearing

10.

Spacer

11.

Shift collar

12.

Snap ring

13.

Spacer

14.

Spacer

15.

Bearings

16.

Snap ring

17.

Bearing

18.

Gearcase

19.

Gear

(16T)

20.

Thrust washer

21.

Gear(22T)

22.

Countershaft

23.

Washers

24.

Bearing

25.

Coupling

26.

Bearing

27.

Pto

drive shaft

ward out

of

housing and withdraw gears

(32

and

33).

To disassemble center case, remove

snap ring, gear (2-Fig. 116) and spacer

Paragraphs 84-85

(3) from front

of pto

gear shaft

(5).

Remove bearing retainer

(9),

then

tap

shaft rearward

out of

case. Remove

bearing retainer, then

tap pto

counter-

shaft (11)

out

front

of

case. Remove

pto

shift rail

and

fork.

To reassemble transmission, reverse

the disassembly procedure while noting

the following:

Be

sure

pto

gear

(6

-

Fig.

116) is installed with chamfered side

for-

ward. Make certain oil grooves

in

thrust

washers (5-Fig. 115)

are

toward splin-

ed sleeves

(8).

Tighten mainshaft

cap

screw

to a

torque

of

50-70

N-m

(36

52

ft.-lbs.)

Be

sure seal washer (2-Fig.

117)

is

installed

on

shift housing

(1)

in

proper location. Tighten seal washer cap

screw

to a

torque

of

12-20

N-m

(9-15

ft.-lbs.)

and

remainder

of

mounting

cap

screws

to

24-27 N-m (18-20 ft.-lbs.).

REAR TRANSMISSION HOUSING

Models L235-L275-L355

85.

REMOVE

AND

REINSTALL.

To remove rear transmission housing.

36

Fig. 115—Exploded view of gears and shafts located in front transmission housing on Model

L355.

Fig. 114—instaif seai washer at iocation

when reinstailing shift housing (1).

1 .Snap

f^

2

.Washer

.'i,

Sftacer

4.

Bearing

5.

Thrust washer

6. Retaining ring

7.

Gear(;ilT)

8. Splined sleeve

9. Retainer clip

]().

Co un te rs ha ft

12.

(iear(44T)

\:i Gear{45T)

14.

Bearing

IT),

('oupiing

IB.

Snap ring

17.

Bearing

18.

Counters haft (range)

19.

Cnu[)ling

20.

Coupling

21.

Countershaft

(pto)

ZZ.

bnap ring

2'J. Bearing

24.

Coupling

25.

Cap

screw

26.

Washer

& pin

27.

GeardHT)

28.

Spacer

2V>.

Bearing

;iO.

Case

'.l\.

Bearing

H2.

Gear(24T)

XI

Gear(20T)

'M.

Mainshaft

;{;").

Bearing

'J6.

Snap ring

43

Loading...

Loading...