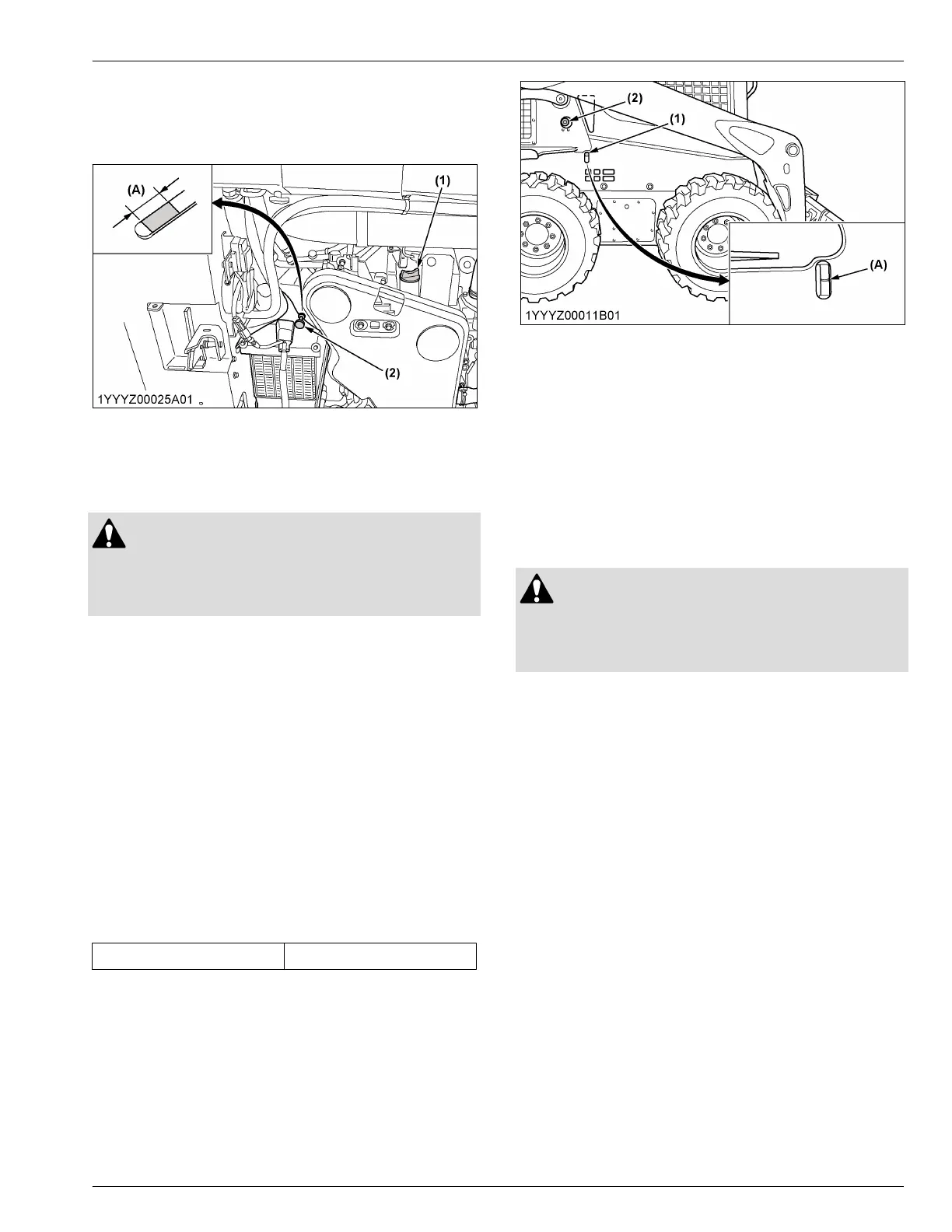

5. Check to see that the oil level lies between the two

notches.

6. If the level is too low, add new oil to the prescribed

level at the oil filling port.

(1) Oil filling port

(2) Engine oil dipstick

(A) Required oil level range

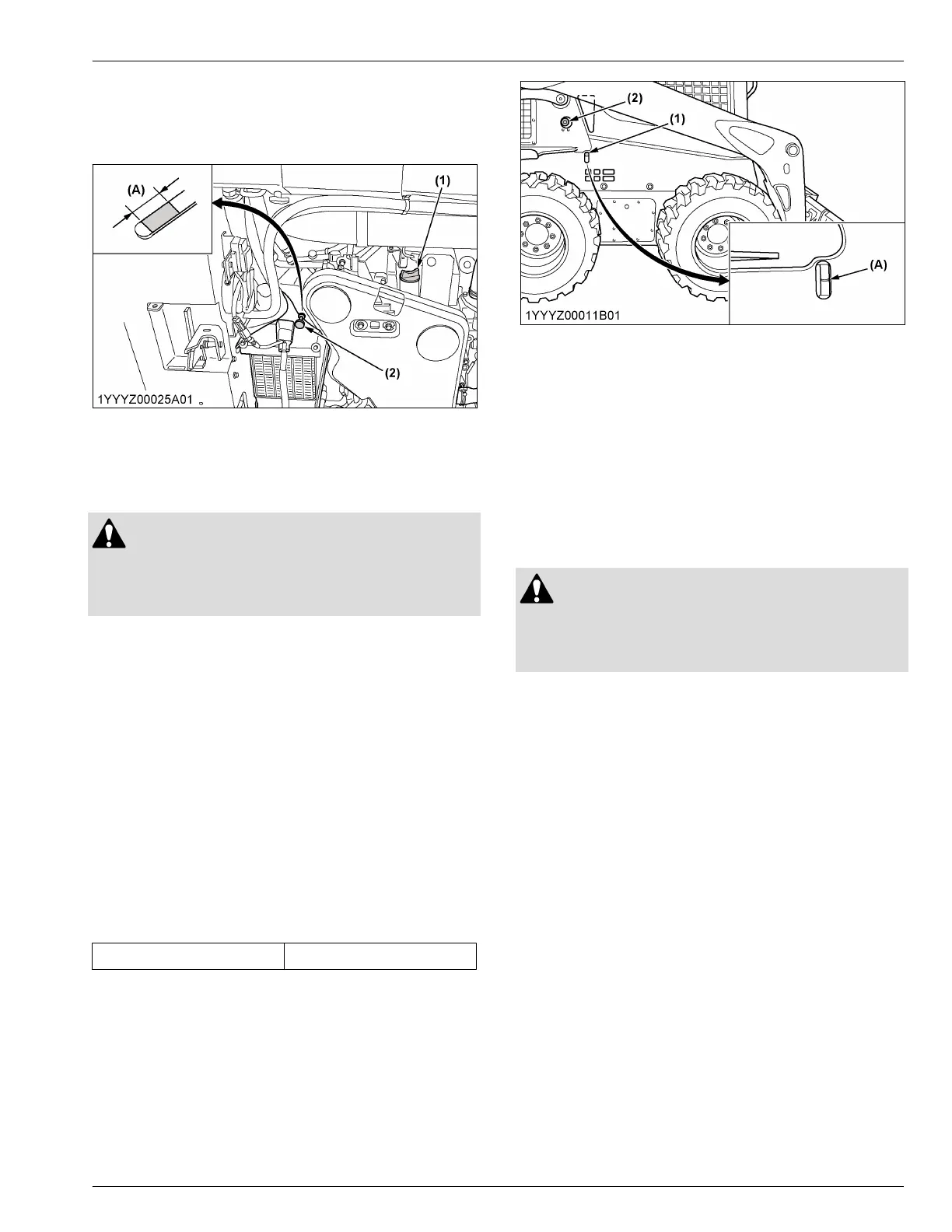

5. Checking the hydraulic oil level

WARNING

To avoid personal injury or death:

• Stop the engine and remove the key before

checking the oil level.

IMPORTANT :

• Before filling oil, wipe away all sand and dust

from around the oil port. Make sure to use an

identical type of hydraulic fluid.

• The machine has been filled with hydraulic fluid

before delivery.

(See RECOMMENDED OILS, GREASES, AND

FUELS on page 122)

Do not mix different oils.

1. Park the machine on a firm, flat, and level surface.

2. Lower the lift arms slowly to the ground.

3. Tilt down the attachments.

4. Stop the engine.

5. Check the oil level as to whether it lies on the

center of the gauge at normal temperature.

Normal temperature

10 ℃ to 30 ℃

(1) Gauge

(2) Hydraulic tank cap (Oil filling

port)

(A) Center of the gauge

Enough oil is present if the oil level lies near the

center of the gauge.

6. If the oil level is too low, fill up with oil through the

oil port before starting the engine.

This step is important for the protection of the

hydraulic system.

6. Lubrication points of the machine

WARNING

To avoid personal injury or death:

• First lower all attachments on the ground, and

then stop the engine and remove the key.

IMPORTANT :

• When using the loader in water, generously

grease the following points. After ending work

with the loader, grease again.

Grease the marked grease fittings (both sides) shown

by arrows in the following illustration.

DAILY CHECKS MAINTENANCE

Loading...

Loading...