2RV/2RW/2RX/2RY/3RA-3

7-25

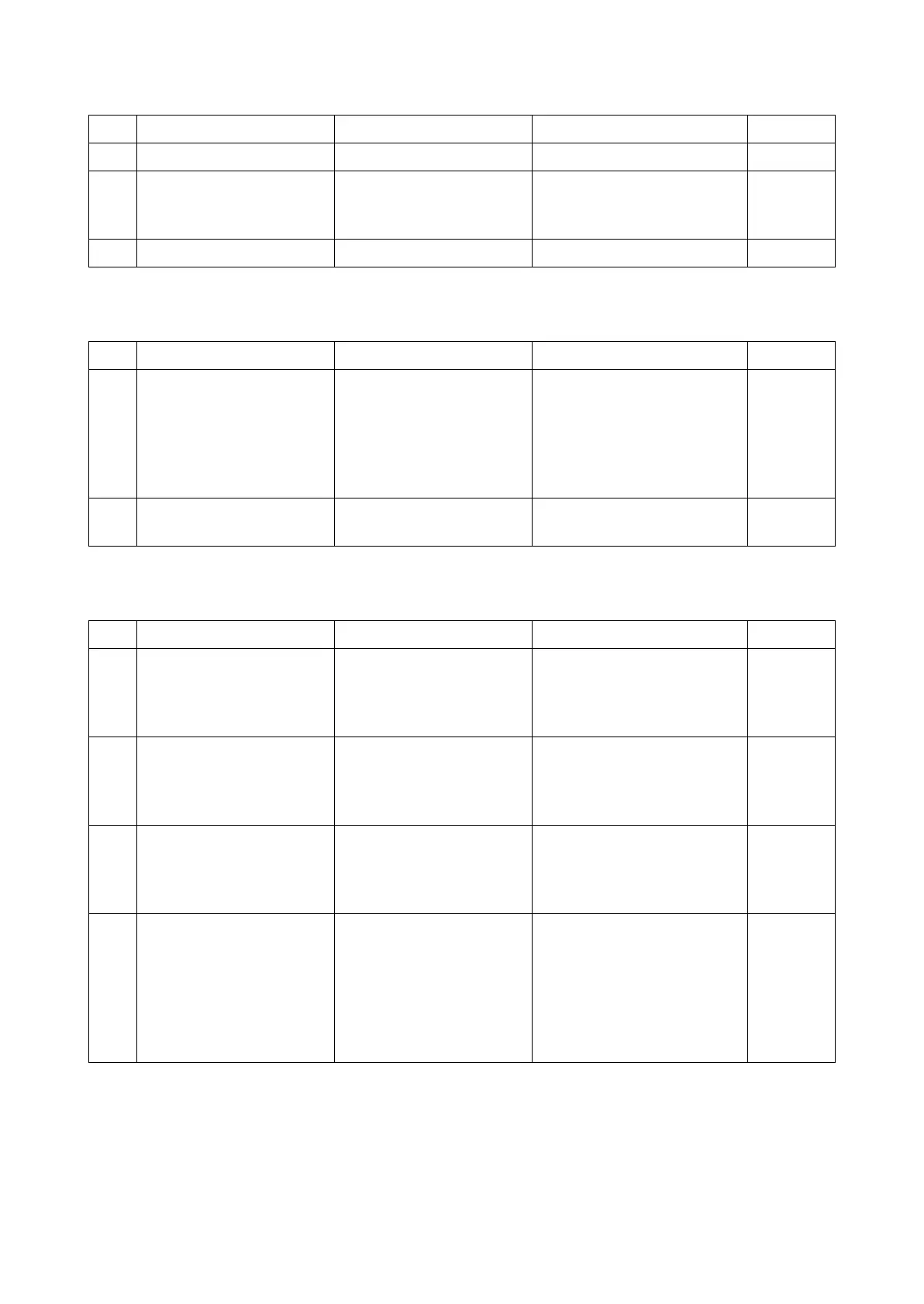

(1-2) Paper jam due to the wave or curl in the fuser section of the damp paper

(1-3) Paper jam due to dog-ear, skew, crease. fusing failure, curl, etc.

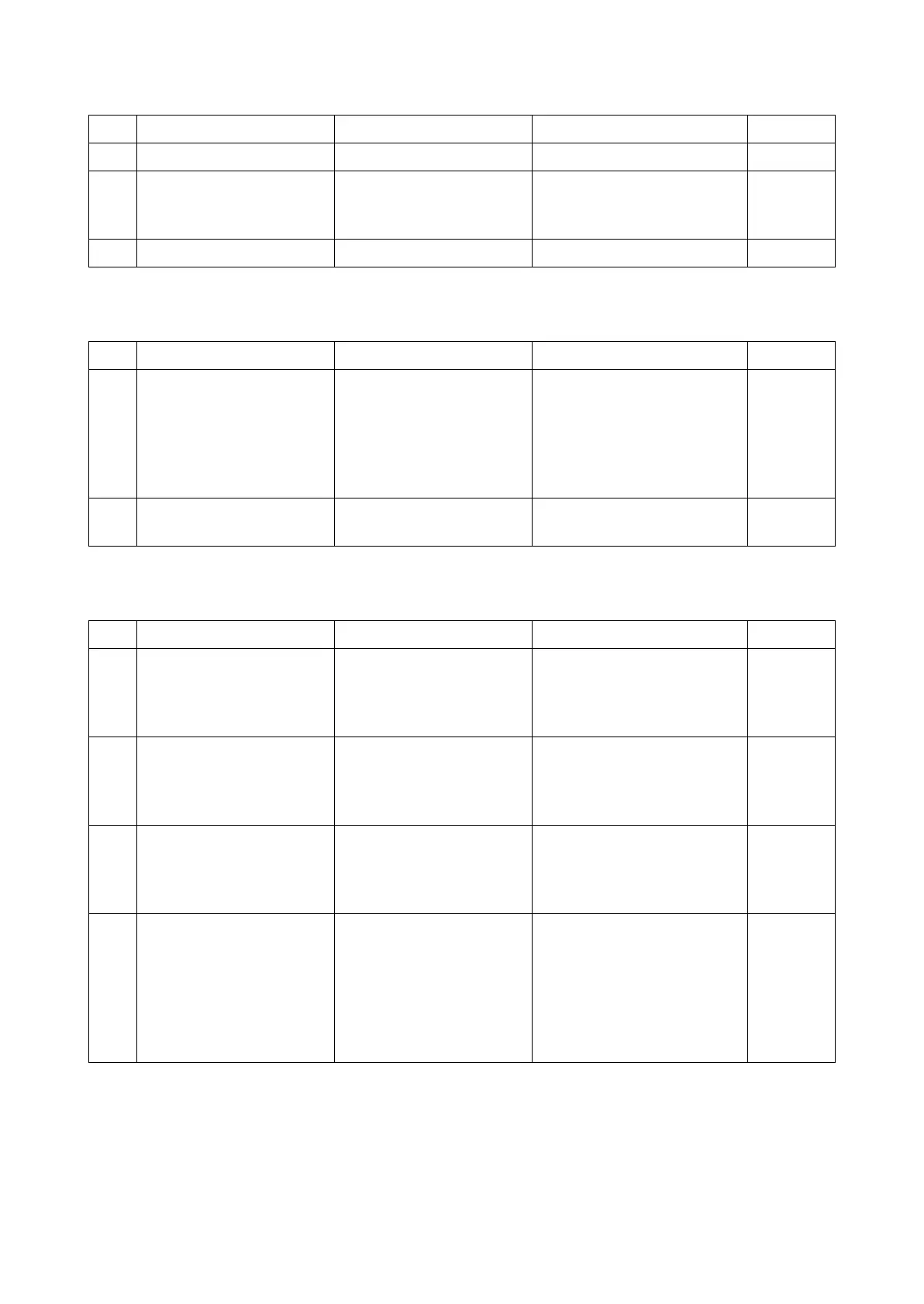

(1-4) Paper jam due to the guide factor

Step Check description Assumed cause Measures Reference

1 Re-loading paper The paper curls. Reload paper upside down.

2 Re-loading paper The paper fanning is not

enough.

Fan the paper well and load it

by reversing the paper direc-

tion

3 Replacing the paper The paper is damp. Replace the paper.

Step Check description Assumed cause Measures Reference

1 Checking the paper path

and the paper

Paper is caught up by a

piece of paper or paper

leading edge is bent.

If there is a piece of paper,

foreign object or burr on the

part on the conveying path,

remove them. If the paper

leading edge is bent, remove

the paper.

2 Changing the settings Media type is not set prop-

erly.

Select the proper media type

in the system menu.

Step Check description Assumed cause Measures Reference

1 Checking the paper path The paper is caught with a

piece of paper, etc.

If there is a piece of paper,

foreign object or burr on the

part on the conveying path,

remove them.

2 Cleaning the guide and

separation needle

The guide and separation

needle are dirty.

If the guide or separation

needle is dirty with toner or

paper dust, clean it with a

cleaning cloth or brush.

3 Reattaching / replacing the

guide

The guide does not prop-

erly operate due to the

incorrect attachment or a

fault.

If the guide does not

smoothly move manually,

reattach it. If not repaired,

replace it.

4 Checking the solenoid The solenoid does not

operate properly.

Test print and check the

guide operation with the

operation sound. If the guide

does not operate or it is not

smooth, reattach the guide. If

not repaired, replace the

solenoid.

Loading...

Loading...