FS-9120DN/9520DN

1-5-35

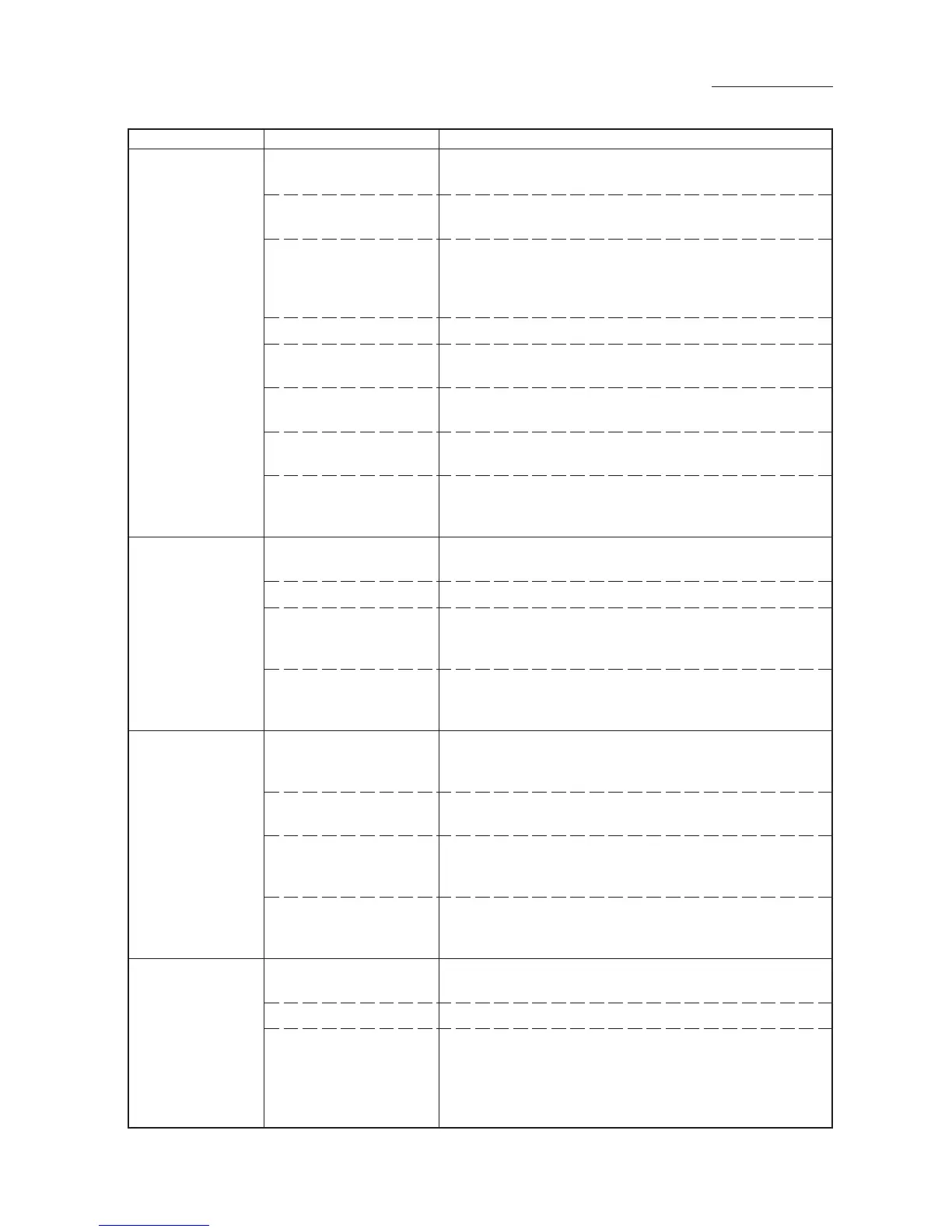

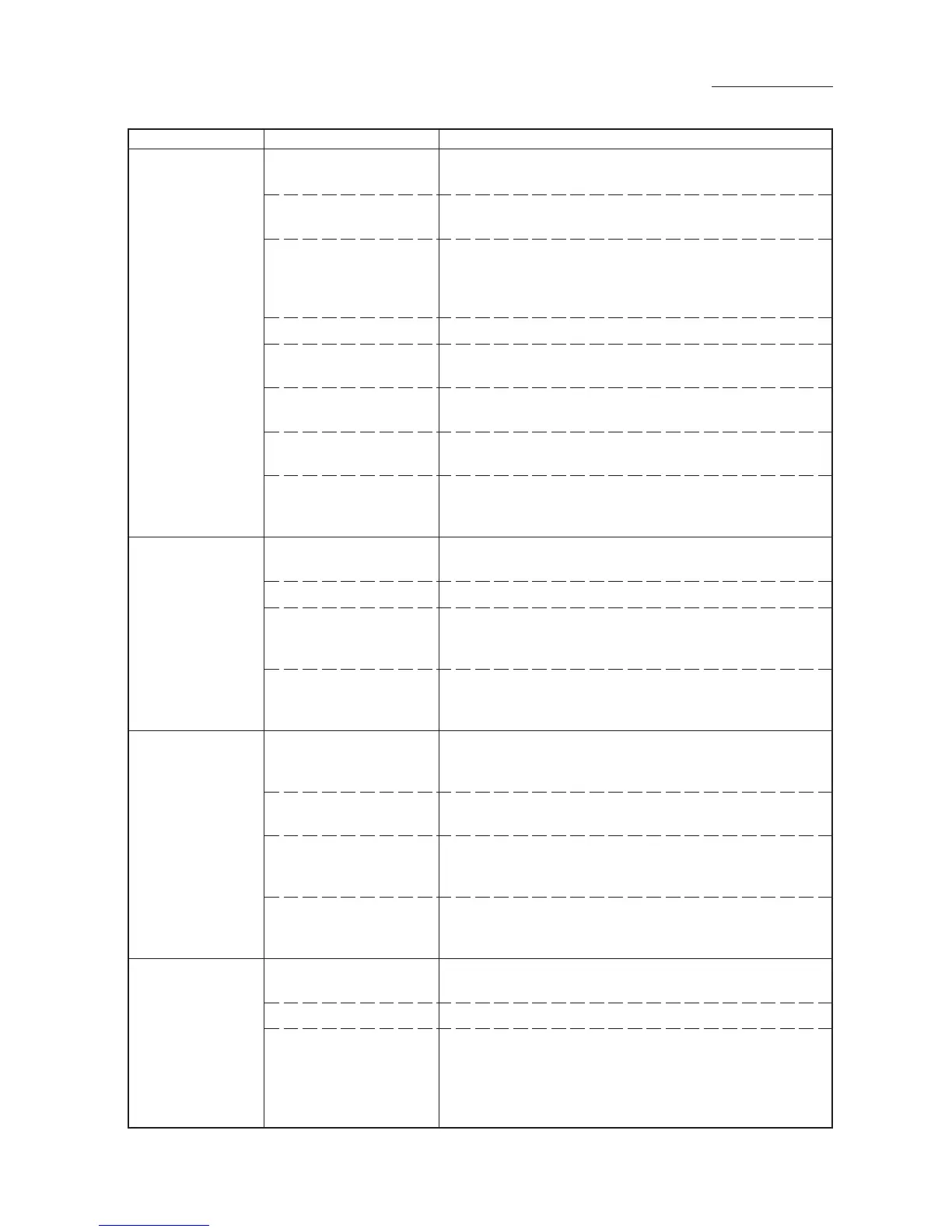

1-5-4 Electrical problems

Problem Causes Check procedures/corrective measures

(1)

The machine does

not operate when

the power switch is

turned on.

(2)

The drive motor

does not operate

(C2000).

(3)

The paper feed mo-

tor does not operate

(C2500).

(4)

The eject motor

does not operate.

No electricity at the power

outlet.

The power cord is not

plugged in properly.

The front cover, conveying

cover and/or side cover

are/is not closed com-

pletely.

Broken power cord.

Defective power switch.

Blown fuse in the power

supply unit.

Defective safety switch 1

or 2.

Defective power supply

unit.

Poor contact in the drive

motor connector terminals.

Broken drive motor gear.

Defective drive motor.

Defective engine controller

PWB.

Poor contact in the paper

feed motor connector ter-

minals.

Broken paper feed motor

gear.

Defective paper feed mo-

tor.

Defective engine controller

PWB.

Poor contact in the eject

motor connector terminals.

Broken eject motor gear.

Defective eject motor.

Measure the input voltage.

Check the contact between the power plug and the outlet.

Check the front cover, conveying cover and side cover.

Check for continuity. If none, replace the cord.

Check for continuity across the contacts. If none, replace the

power switch.

Check for continuity. If none, remove the cause of blowing and

replace the fuse.

Check for continuity across the contacts of each switch. If none,

replace the switch.

With AC present, check for 24 V DC at YC1-1 and 5 V DC at

YC2-5 on the power supply unit. If none, replace the power sup-

ply unit.

Reinsert the connector. Also check for continuity within the con-

nector cable. If none, remedy or replace the cable.

Check visually and replace the drive motor if necessary.

Run maintenance item U030 and check if the drive motor oper-

ates when YC11-9 on the engine controller PWB goes low. If

not, replace the drive motor.

Run maintenance item U030 and check if YC11-9 on the engine

controller PWB goes low. If not, replace the engine controller

PWB.

Reinsert the connector. Also check for continuity within the con-

nector cable. If none, remedy or replace the cable.

Check visually and replace the paper feed motor if necessary.

Run maintenance item U030 and check if the paper feed motor

operates when YC11-10 on the engine controller PWB goes low.

If not, replace the paper feed motor.

Run maintenance item U030 and check if YC11-10 on the en-

gine controller PWB goes low. If not, replace the engine control-

ler PWB.

Reinsert the connector. Also check for continuity within the con-

nector cable. If none, remedy or replace the cable.

Check visually and replace the eject motor if necessary.

Run maintenance item U030 and check if the eject motor oper-

ates when YC16-B11, YC16-B12, YC16-B13 and YC16-B14 on

the engine controller PWB go low. If not, replace the eject motor.

Loading...

Loading...