FS-9120DN/9520DN

2-3-1

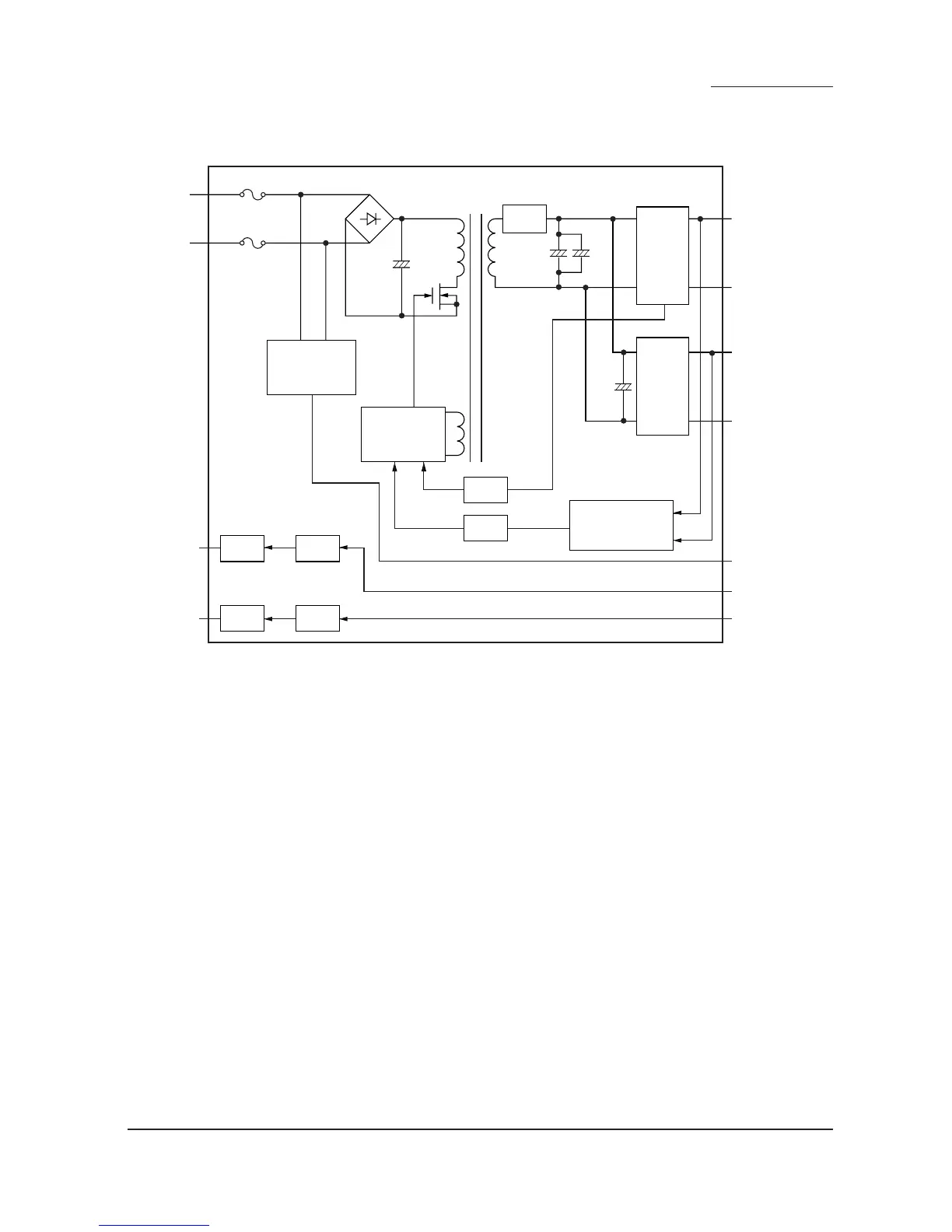

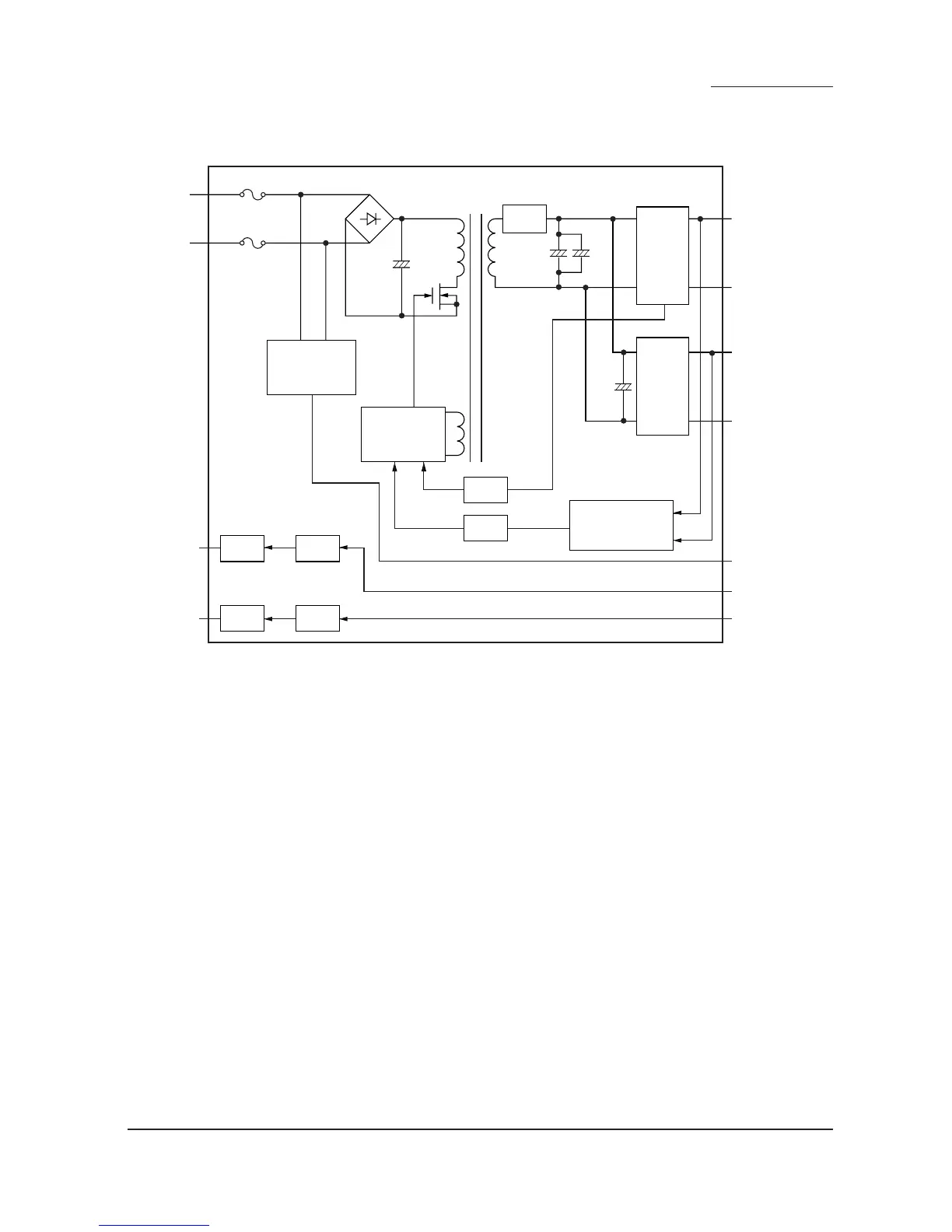

2-3-1 Power supply unit

C201

C102

C101

D3

F1

F2

C5

+

++

+

Q1

T1

24 V DC

AC input

Power supply unit

Rectifier circuit

Fuser heater

control circuit

HEATER

MAIN ON

HEATER

SUB ON

GND

5 V DC

GND

HEATER

REM1

HEATER

REM2

ZERO CROSS

OUT

24 V DC

output

circuit

5 V DC

output

circuit

Switching

control circuit

IC1

D101

D102

Zero-cross

circuit

PC3

Overvoltage

detection circuit

IC201

PC1

PC2

TRA1

TRA2

PC5

PC4

Figure 2-3-1 Power supply unit block diagram

The power supply unit (PSU) is a switching regulator that converts an AC input to generate 24 V DC and 5 V DC. It includes

a rectifier circuit, a switching regulator circuit, a 24 V DC output circuit, a 5 V DC output circuit and a fuser heater control

circuit.

The rectifier circuit full-wave rectifies the AC input using the diode bridge D3. The smoothing capacitor C5 smooths out the

pulsed current from the diode bridge.

In the switching control circuit, PWM controller IC1 turns the power MOSFET Q1 on and off to switch the current induced in

the primary coil of the transformer T1.

The 24 V DC output circuit smooths the current induced in the secondary coil of the transformer T1 via diodes D101 and

D102 and smoothing capacitors C101 and C102, and the output is controlled by the overvoltage detection circuit IC201 and

the power MOSFET Q201. For 24 V DC output, the PWM controller IC (IC1) of the switching control circuit changes the duty

of the switching pulse width of the power MOSFET Q1 via a photo coupler PC4 based on the output voltage status to adjust

the 24 V DC output.

The 5 V DC output circuit smooths the current induced in the secondary coil of the transformer T1 via diodes D101 and D102

and smoothing capacitors C101 and C102, and the output is controlled by the overvoltage detection circuit IC201 and the

power MOSFET Q201. For 5 V DC output, the PWM controller IC (IC1) of the switching control circuit changes the duty of

the switching pulse width of the power MOSFET Q1 via a photo coupler PC5 based on the output voltage status to adjust the

5 V DC output.

The overvoltage detection circuit IC201 monitors the overvoltage status of 24 V DC and 5 V DC, and when it detects an

abnormal status, it gives immediately feedback to the PWM controller IC (IC1) via a photocoupler PC5 to stop control

operation and moves the power source to a standby condition.

The fuser heater control circuit sends a waveform of which zero-cross is detected to the engine controller PWB (EPWB),

which controls the timing of HEATER REM 1 and 2 based on it to turn on the phototriacs PC1 and PC2. When the

phototriacs PC1 and PC2 turn on, AC current flows through the triacs TRA1 and TRA2 to turn the fuser heaters M and S on.

Loading...

Loading...