224

8 CO/O

2

Control

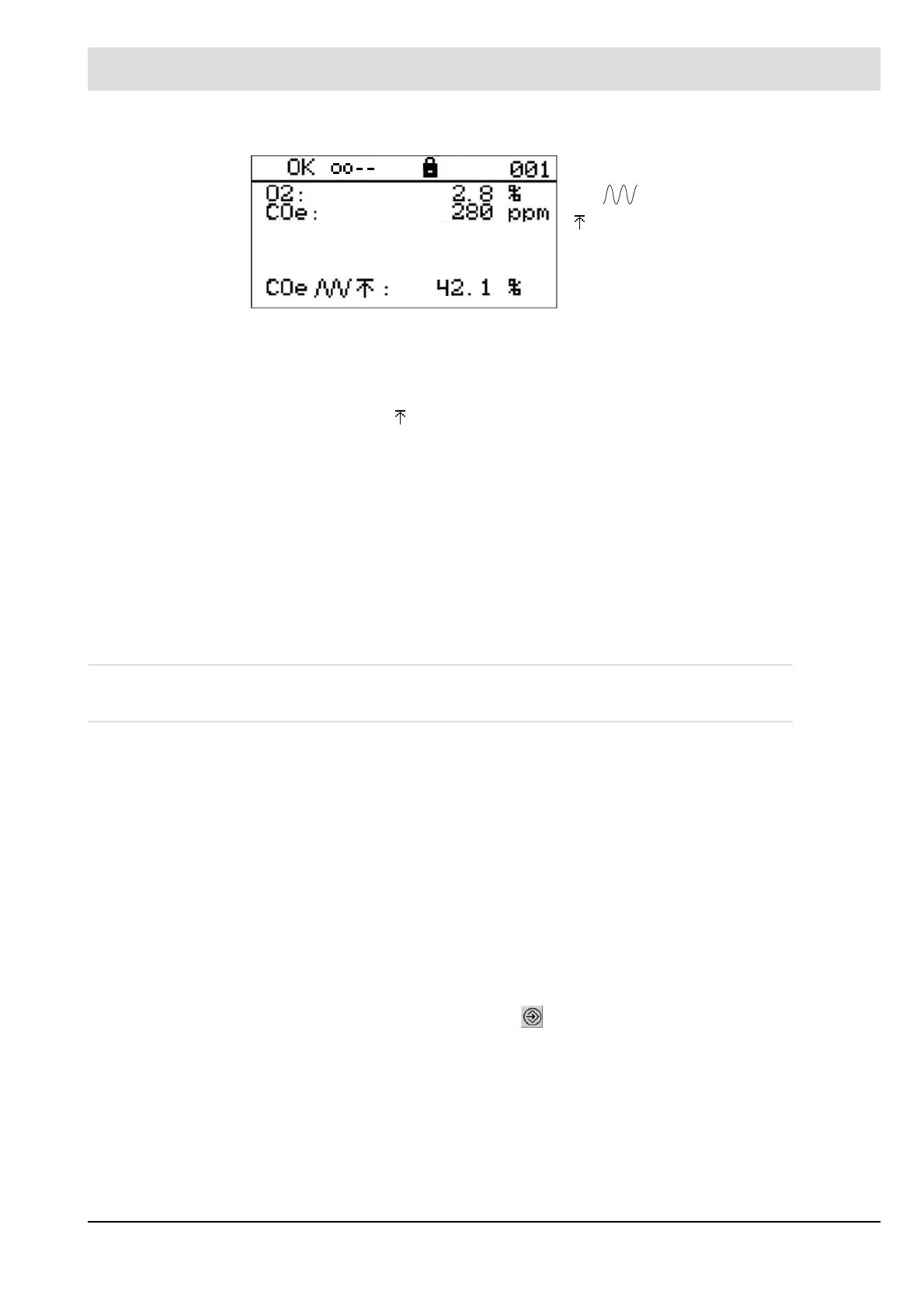

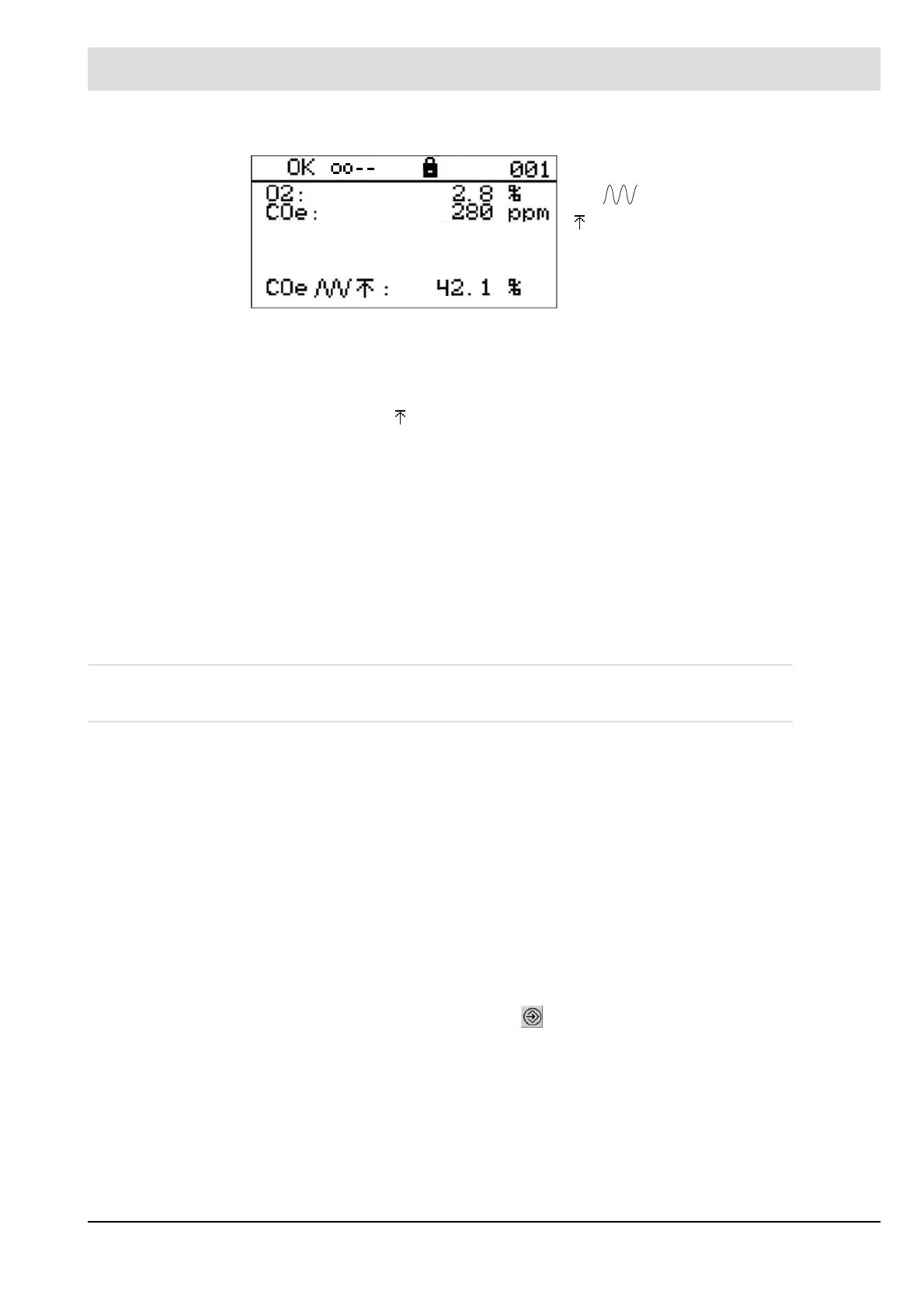

The factory-set response threshold is 40%. The display of the LT3-F shows whether or not the

response threshold has been reached. When the response threshold is reached, the CO edge

signal is present, and the CO regulation becomes active. This is indicated by a symbol on the

display of the LT3-F or can be exported via the LSB remote software of the LT3-F in pa-

rameter 444. The desired response threshold can be set on the display of the LT3-F or using

Parameter 453 of the LSB remote software of the LT3-F. Access level 2 is required for service!

Setting recommendation:

– For burners without a CO base level, the response threshold in the LT3-F should be set in

such a way that the CO edge is at 20 10 ppm CO (measured using a CO reference

measuring device).

– For burners without a CO base level, the response threshold value should be set to values

80 ppm CO (measured using a CO reference measuring device).

– Setting increments 10%

8.10.8 Commissioning the CO/O

2

Control

8.10.8.1 Resetting Faults

Faults are reset in different ways:

Resetting temporary faults (ot):

The fault is displayed for as long as it is present. Once the cause of the fault is eliminated, the

fault is deleted, and the fault status signal no longer displayed.

Resetting permanent faults (od) at startup of the burner:

Each time the burner starts up, a fault is automatically reset, even if the cause of the fault has

not yet been eliminated. If the cause has not yet been eliminated, the fault will re-occur.

Resetting permanent faults (od) manually:

You can also reset permanent faults (od) manually after eliminating the cause.

UI400: Open the fault status signal using the arrow keys (see chapter Calling the CO/O

2

Fault

History) and acknowledge the fault with .

CMS Remote Software: Use the RESET buttons in the header bar of the CMS Remote Soft-

ware.

Fig. 8-15 Main menu in the LT3-F

O2 O

2

in humid flue gas

COe evaluated CO

e

signal

COe Signal dynamics U

CO/H2

CO edge signal reached/

exceeded

Loading...

Loading...