Page 15

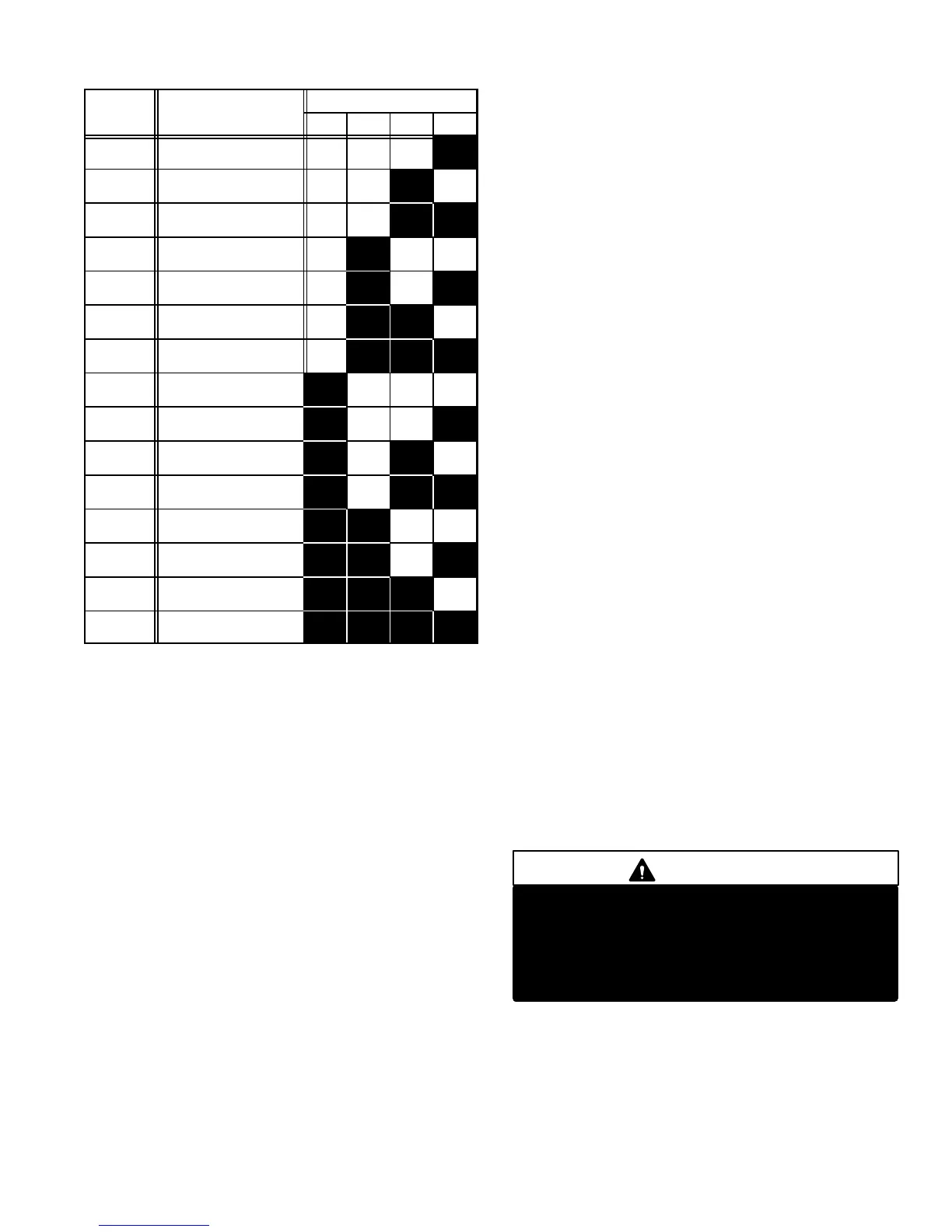

TABLE 8

TSC-6 DIAGNOSTICS CODES

CODE

DISPLAY LIGHTS

NUMBER

CONDITION

8 4 2 1

1 Power loss for two

cycles

OFF OFF OFF ON

2 Input Indication OFF OFF ON OFF

3 Unsteady Input OFF OFF ON ON

4 Pressure Switch Open

<2 minutes

OFF ON OFF OFF

5 Pressure Switch Open

> 2 minutes

OFF ON OFF ON

6 Hot Compressor < 5

min. (or open sensor)

OFF ON ON OFF

7 Hot Compressor > 5 min.

(or open sensor)

OFF ON ON ON

8 Option 1 < 5 minutes ON OFF OFF OFF

9 Option 1 > 5 minutes ON OFF OFF ON

10 Option 2 Open ON OFF ON OFF

11 Compressor Temp.

Sensor Problem

ON OFF ON ON

12 Outdoor temperature

Sensor

ON ON OFF OFF

13 Not Used ON ON OFF

ON

14 Test Mode ON ON ON OFF

15 No Jumper in place

Indication

ON ON

ON

ON

Code 7 − Hot Compressor > Five Minutes

Code 7 indicates the compressor temperature exceeded

its limit after running more than five minutes. Code 7 is

stored.

Code 8 − Option 1 < Five Minutes

Code 8 occurs if the Option 1 safety device switch opens af-

ter the compressor runs less than five minutes. Code 8 is

stored.

Code 9 − Option 1 > Five Minutes

Code 9 occurs if the Option 1 safety device switch opens after

the compressor runs more than five minutes. Code 9 is

stored.

Code 10 − Option 2

Code 10 is displayed if the Option 2 safety device switch

opens. Code 10 is stored.

Code 11 − Compressor Temperature Sensor Shorted

This code indicates that the compressor temperature sensor

wires have shorted together. Code 11 is stored.

Code 12 − Outdoor Temperature Sensor

This code indicates a problem with the operation of the out-

door temperature sensor. Code 12 is stored.

Code 13 − Not Used

This code may be used in future models of the two−speed con-

trol, but at this time has no function and, therefore, is not

stored.

Code 14 − Test Mode

Code 14 does not indicate a problem. The control is in TEST

mode when this code is displayed. See Mode Jumper Selec-

tions section.

Code 15 − No Jumper in Place

Code 15 is displayed when the mode jumper is not in place.

Make sure jumper is placed securely across the selected set of

pins for the appropriate mode of operation.

SERVICE RELAY

The control has a built-in service relay. This relay controls the

thermostat service light or communicates with an alarm de-

vice. The relay signals the alarm device in such a manner that

the alarm device can distinguish between a lock out and a non-

lock out condition. The relay contacts are normally open when

no problems or lock out conditions occur. A non-lock out condi-

tion is reported by closing the contacts for the duration of the

next no-demand period. If the control goes into a lock out state,

the relay will close and remain closed until the next loss of de-

mand. If the service light on the room thermostat is connected

to the service relay, the light will turn on if the control is in a lock

out. It will not turn on if the control is detecting non-lock out

problems. In order for the service relay to indicate only a lock

out condition, one side of the relay must be wired to the alarm

and the other side to Y2. During a simultaneous Y1, Y2 de-

mand with a non-lock out condition, the alarm will energize for

a very short duration (.2 seconds). If both an alarm device and

thermostat service lights are used, an additional external relay

may be required depending on thermostat used.

OPTIONAL INPUTS

The control has two optional inputs for additional protection de-

vices. If options 1 or 2 are going to be used, move the three pin

mini-jumper to the YES side. OPT 1 input will lock out the com-

pressor on the third count. OPT 2 input will not lock out the

compressor at any time, but will display and store the problem

code (see Diagnostic code Table). These inputs are designed

for normally closed switches connected to 24VAC.

CAUTION

Do not remove the jumpers unless additional

protection controls are going to be installed. If OPT

1 jumper is not connected to the NO pin, the control

will lock out the compressor. If OPT 2 is not con-

nected to the NO pin, the display only shows the

problem code.

The unit wiring diagrams have been revised to reflect the

changes for the HP21-4/-5 (TSC-6), and are shown in section

VII−Wiring Diagrams and Operation Sequence.

Loading...

Loading...