Page 20

III−REFRIGERANT SYSTEM

A−Field Piping

Field refrigerant piping consists of liquid and vapor lines

from the outdoor unit (sweat connections). Use Lennox

L10 series line sets as shown in table 13 or field fabricated

refrigerant lines. Refer to the piping section of the Lennox

Service Unit Information Manual (SUI−803−L9) for proper

size, type and application of field−fabricated lines.

MODEL NO.

LIQUID VAPOR L10

LINE LINE LINE SETS

HP21−410

HP21−36

3/8 in. 3/4 in.

L10−41

20 ft. − 50 ft.

HP21−510

HP21−48

3/8 in. 7/8 in.

L10−65

30 ft. − 50 ft.

HP21−650

HP21−60

3/8 in. 1−1/8 in.

FIELD

FABRICATED

TABLE 13

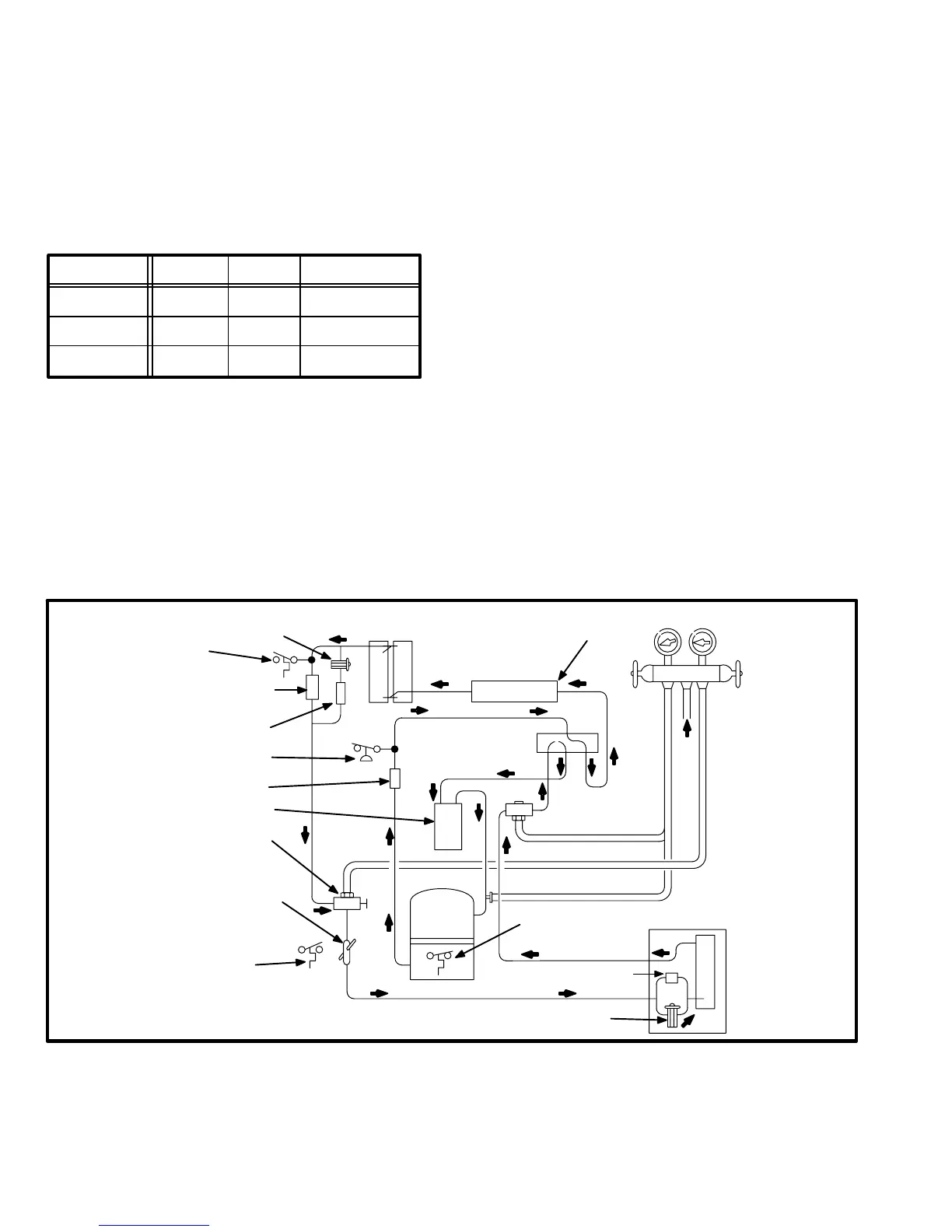

B−Unit Circuitry

Conventional heat pump circuitry is used. A check valve

and expansion valve are used in parallel in the liquid line.

The check valve is closed when the unit is in heating mode

to force refrigerant through the expansion valve. The check

valve is open when the unit is in cooling mode and refriger-

ant is forced through the drier. Separate discharge and

suction service ports are provided at the compressor for

connection of gauge manifold during charging procedure.

Figures 16 and 18 show HP21 gauge connections.

C−Reversing Valve

HP21 units are equipped with a reversing valve which is

used to reverse refrigerant flow. The valve is de-energized

during heating mode to direct discharge gas to the indoor

coil. The valve is energized during cooling mode and dur-

ing defrost to direct discharge gas to the outdoor coil. A 24

volt solenoid is used to energize the reversing valve during

cooling and defrost demand.

D−Strainer

All units are equipped with a liquid line strainer located ad-

jacent to the expansion valve. The strainer is used to

protect the expansion valve from particulate matter enter-

ing the system (such as during charging).

COOLING CYCLE CIRCUITRY

NOTE − Bold arrows indicate direction of

refrigerant flow in cooling mode.

THERMOMETER

WELL

REVERSING

VALV E

GAUGE MANIFOLD

INDOOR UNIT

VAPOR LINE

VALV E

VALV E

LIQUID LINE

EXPANSION

VALV E

COMPRESSOR

HIGH

PRESSURE

SWITCH

STRAIN-

ER

FILTER/DRIER

WITH INTERNAL

CHECK VALVE

OUTDOOR

COIL

DEFROST CONTROL

SENSOR

DEFROST CONTROL

AMBIENT SENSOR

CHARGE

COMPENSATOR

CHECK

VALV E

EXPANSION

VALV E

CRANKCASE

THERMOSTAT

ACCUMULATOR

MUFFLER

FIGURE 16

Loading...

Loading...