Page 3

506373−01 11/2011

Never test for gas leaks with an open flame. Check all

connections with a commercially available soap solution

made specifically for leak detection.

NOTE − Furnace must be adjusted to obtain a

temperature rise (high and low fire) within the range(s)

specified on the unit nameplate. Failure to do so may

cause erratic limit operation.

Canada

The unit is CSA International (CSA) certified for

combination heating/cooling for outdoor installations and

non−residential use only at the clearances to combustible

materials as listed on the unit nameplate.

Installation of CSA international certified units must

conform with current standard CSA B149.1, Natural Gas

and Propane Installation Codes" and applicable local

codes. Authorities having jurisdiction should be consulted

before installation.

The unit must be wired and electrically grounded

according to local codes or, in the absence of local codes,

current CSA Standard C22.1 Canadian Electrical Code

Part 1. Installation of combination heating/cooling units

must also conform with current CSA Standard B52

Mechanical Refrigeration Code."

Connect Gas Piping

A manual main shut−off valve must be installed external

to the unit when local codes require the installation of

such a valve.

Install a ground joint union between the gas control

manifold and the main manual shut−off valve.

When making piping connections a drip leg should be

installed on vertical pipe runs to serve as a trap for

sediment or condensate.

A 1/8" N.P.T. plugged tap is located on gas valve for test

gauge connection. See figure 4 or 5 for tap location. See

figure 6 for for gas supply piping entry through the side of

the unit and figure 7 for gas piping through the bottom of

the unit. A kit is required when routing gas supply piping

through the bottom of the unit.

Compounds used on threaded joints of gas piping must

be resistant to the actions of liquified petroleum gases.

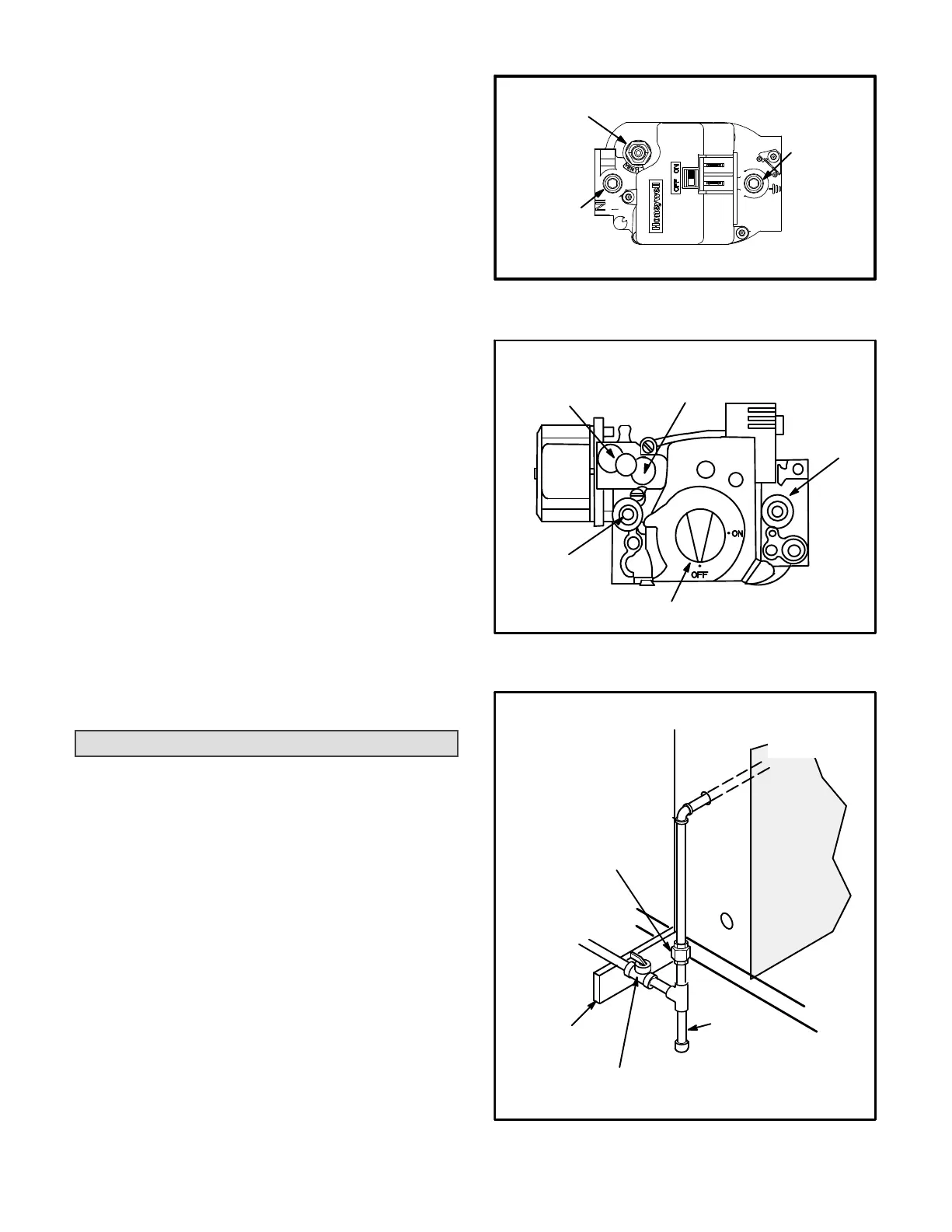

GAS VALVE SHOWN IN ON POSITION

Honeywell VR8205 Gas Valve with ON/OFF Lever

Single−Stage

MANIFOLD

PRESSURE

OUTLET

INLET

PRESSURE

PORT

MANIFOLD

PRESSURE

ADJUSTMENT

SCREW

FIGURE 4

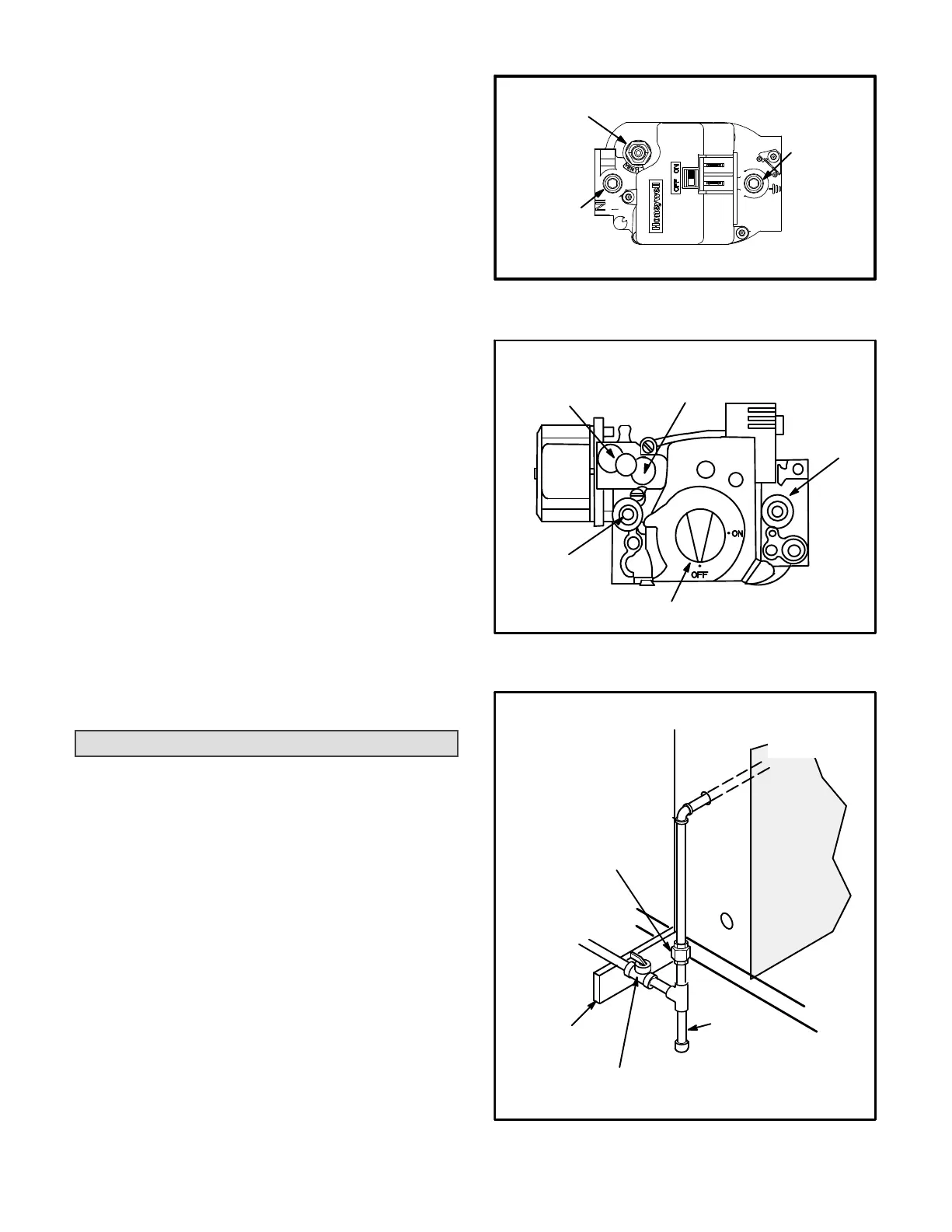

HONEYWELL VR8205Q/VR8305Q SERIES GAS VALVE

Gas valve knob is shown in OFF position.

FIGURE 5

LOW FIRE

ADJUSTMENT

HIGH FIRE

ADJUSTMENT

MANIFOLD

INLET

PRESSURE

TAP

MANIFOLD

OUTLET

PRESSURE

TAP

FIGURE 6

TO GAS

SUPPLY

MANUAL MAIN

SHUT−OFF VALVE

GAS PIPING

SUPPORT

GROUND

JOINT UNION

(REFER TO

LOCAL CODES)

DRIP LEG

OUTSIDE OF UNIT GAS PIPE CONNECTION

TO GAS

VALVE

Loading...

Loading...