Page 12

LGH/LCH036, 048, 060, 072

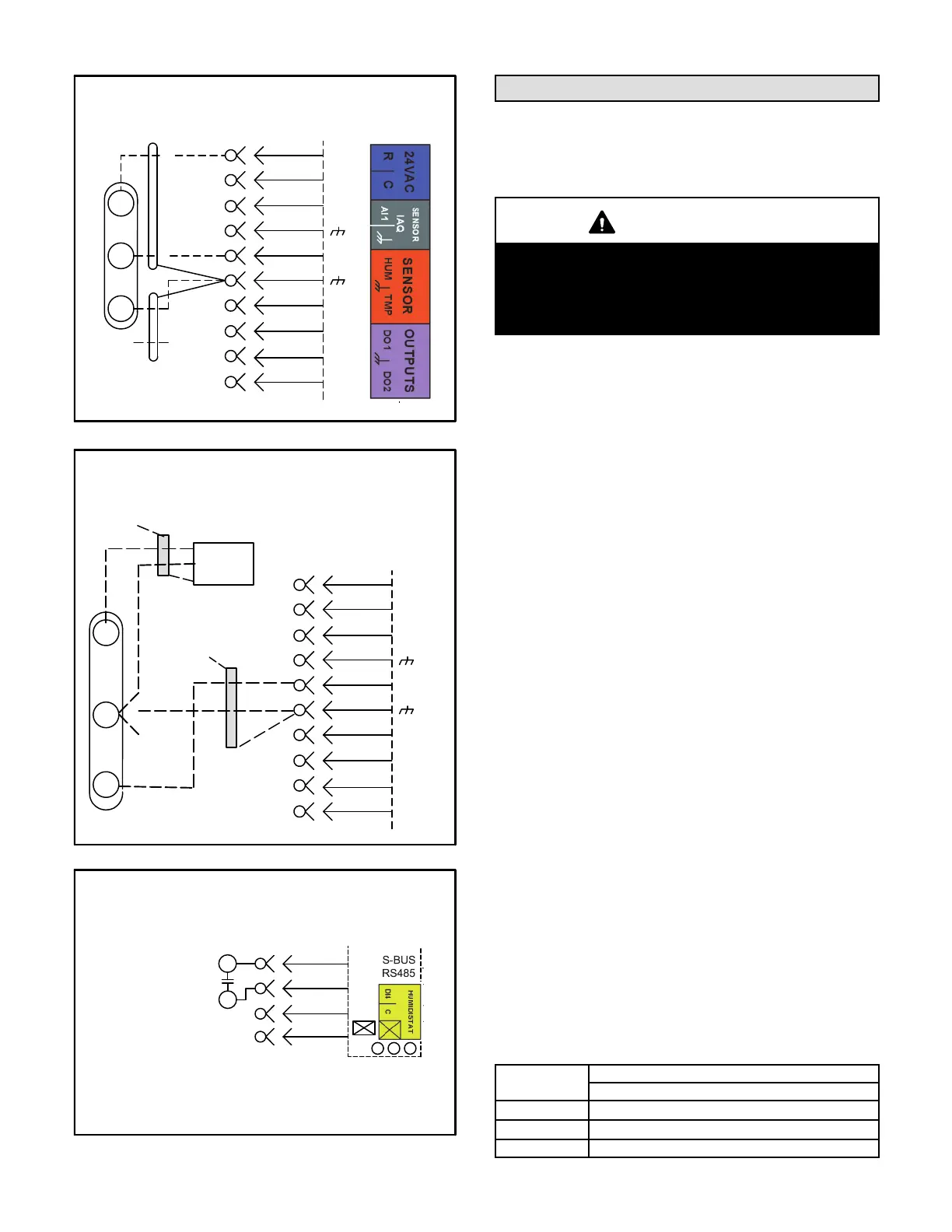

FIGURE 16

FIELD WIRING REHEAT UNITS (Using A Humidity

Sensor With Less Than 150 Ft. Wire Runs)

9

8

10

11

12

2

J262B

5

P298

J298A

6

1

2

B

3

4

C

5

6

7

D

10

A91

VIN

VO

GND

P262

R

C

AI−1

HUM

TMP

DO−1

C

DI−1

DO−2

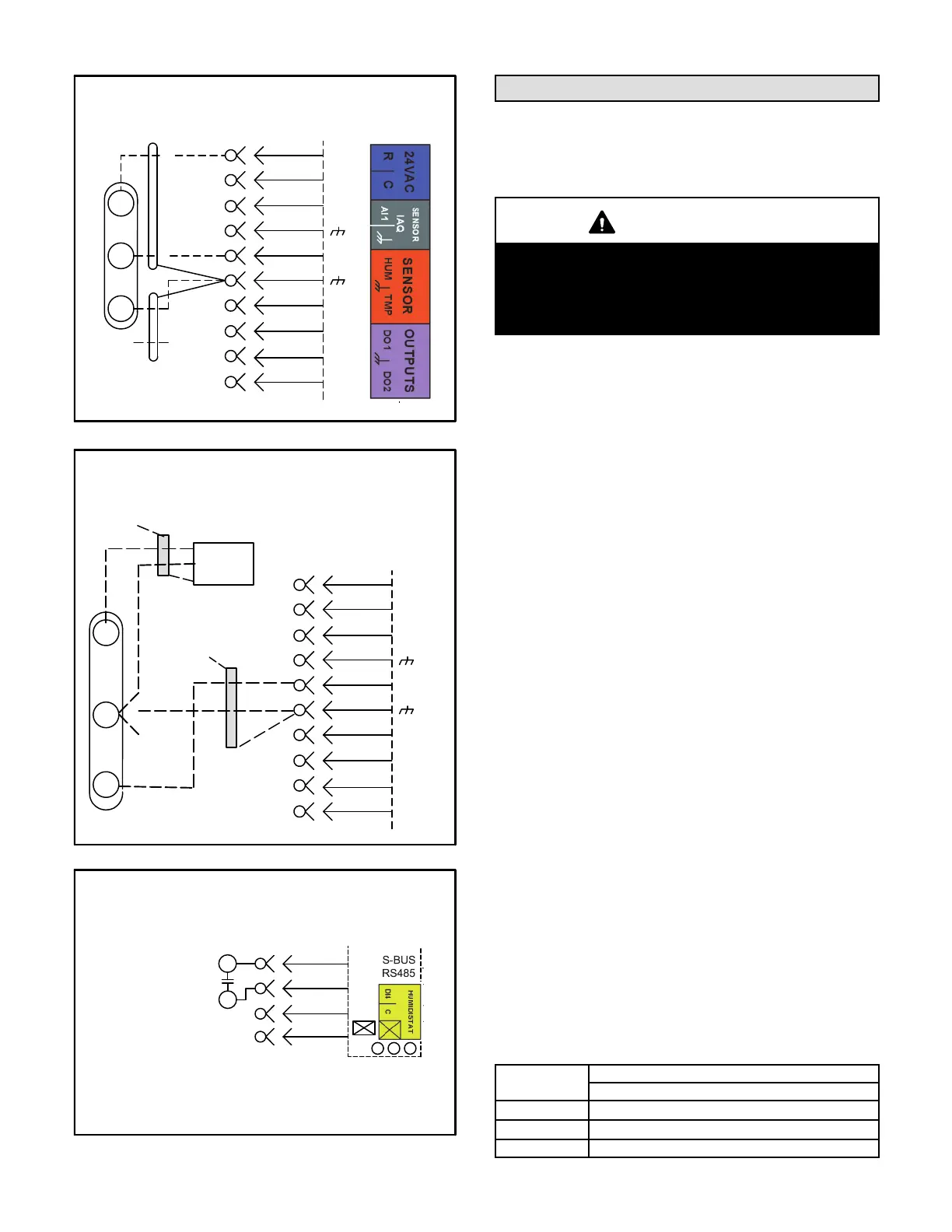

FIGURE 17

FIELD WIRING REHEAT UNITS (Using A Humidity

Sensor With More than 150 Ft. Wire Runs)

ISOLATED 24V

TRANSFORMER

9

8

P298

J298A

1

2

B

3

4

C

5

6

7

D

10

A91

VIN

VO

GND

R

C

AI-1

HUM

TMP

DO-1

C

DI-1

DO-2

NOT

CONNECTED

NOT

CONNECTED

DRAIN

A55 UNIT

CONTROLLER

FIGURE 18

FIELD WIRING REHEAT UNITS

(Using A Dehumidification Switch)

7

10

8

9

R

DI−4

C

Use 24 VAC (R) from any terminal

available on J299−2, −5, or −7.

J299

DEHUMIDIFICATION

SWITCH

Blower Operation and Adjustments

Three-, four- and five-ton units are equipped with either

direct drive or multi-pole belt drive blowers. 6-ton units

are available with belt drive blowers only.

IMPORTANT

Three phase scroll compressors must be phased

sequentially for correct compressor and blower

rotation. Follow “COOLING START-UP” section of

installation instructions to ensure proper compres

sor and blower operation.

A-Blower Operation

Refer to the Unit Controller Installation and Setup Guide

to energize blower. Use the menu navigation arrows and

select button; see Service - Test.

B-Determining Unit CFM

1- The following measurements must be made with air

filters in place.

IMPORTANT - On units equipped with direct drive

blowers, determine and adjust high speed CFM before

low speed CFM. Low speed CFM should be adjusted to

2/3 of high speed CFM. A low speed adjustment less than

2/3 of high speed will improve humidity removal; refer to

product data for more information.

2- With all access panels in place, measure static

pressure external to unit (from supply to return).

Blower performance data is based on static pressure

readings taken in locations shown in figure 19.

Note - Static pressure readings can vary if not taken

where shown.

3- Measure the indoor blower wheel RPM.

4- Referring to Page 16 through Page 26, use static

pressure and RPM readings to determine unit CFM.

Use Page 27 when installing units with any of the

options or accessories listed. Refer to table 3 for

minimum airflow when electric heat is installed.

TABLE 3

MINIMUM AIRFLOW-LC UNITS WITH ELECTRIC HEAT

(BELT DRIVE)

Kw

CFM

Downflow & Horizontal Airflow

LCH036HE

1080

LCH048HE

1280

LCH060HE

1600

Loading...

Loading...