Page 13

LGH/LCH036, 048, 060, 072

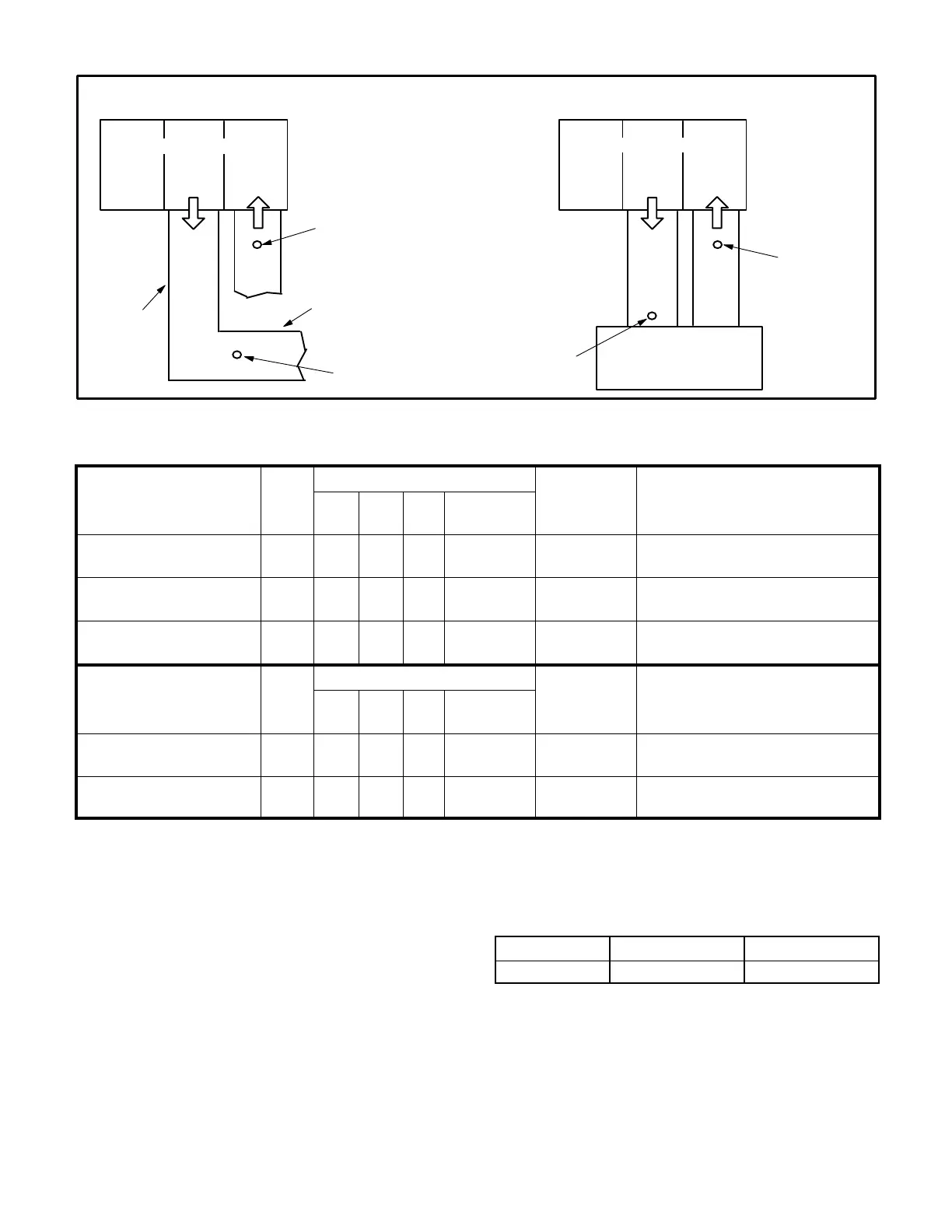

FIGURE 19

LOCATION OF STATIC PRESSURE READINGS

SUPPLY AIR

READING

LOCATION

SUPPLY

RE

TURN

INSTALLATIONS WITH DUCTWORK

SUPPLY

RE

TURN

INSTALLATIONS WITH CEILING DIFFUSERS

MAIN

DUCT RUN

FIRST BRANCH

OFF OF MAIN RUN

DIFFUSER

ROOFTOP UNIT

ROOFTOP UNIT

SUPPLY AIR

READING

LOCATION

RETURN AIR

READING LOCATION

RETURN AIR

READING

LOCATION

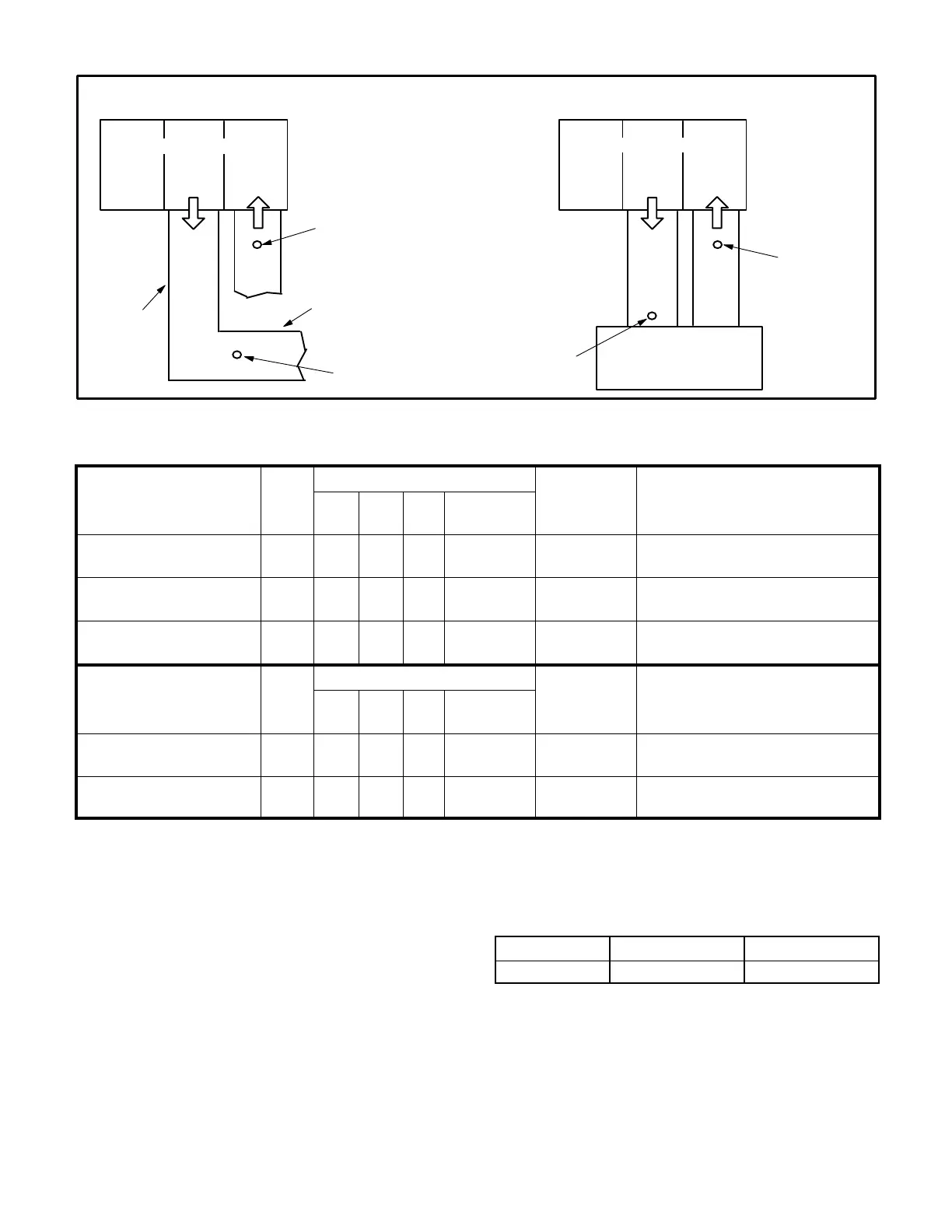

TABLE 4

ECTO SETTINGS

Unit Controller “SET

TINGS-CONTROL-MSAV”

Menu

ECTO

LGH/LCH Unit Factory Settings

Field Setting Description

036

H4E

048

H4E

060

H4E

036-060

S4T

SMOKE SPEED 0.02 55 80 59

Not Applica

ble

% torque for indoor blower smoke

speed.

HIGH SPEED 0.04 55 80 59

Not Applica

ble

% torque for indoor blower high

speed.

LOW SPEED 0.05 28 40 36

Not Applica

ble

% torque for indoor blower low

speed.

Unit Controller “SET

TINGS-SETPOINTS-

DAMPER” Menu

ECTO

LGH/LCH Unit Factory Settings

Field Setting Description

036

H4E

048

H4E

060

H4E

036-060

S4T

MIN OCP BLOWER LOW 0.09 15 15 15

Not Applica

ble

Damper minimum position during

low indoor blower.

MIN OCP BLOWER HIGH 5.24 10 10 10 10

Damper minimum position during

high indoor blower.

Installer: Circle applicable unit model number and record any ECTO changes under “Field Setting” column. Settings need to be recorded by

installer for use when unit controller is replaced or reprogrammed. Refer to unit controller guide “Setting” menu path or use optional software to

change settings.

C-Adjusting Unit CFM - Direct Drive Blowers

The supply CFM can be adjusted by changing Unit

Controller settings; see Settings - Control - MSAV menu.

Refer to table 4. Adjustments can also be made by using

optional software. Record any CFM changes on the

ECTO Settings label located on the inside of the

compressor access panel.

D-Adjusting Unit CFM - Belt Drive Blowers

The blower RPM can be adjusted at the motor pulley.

Loosen Allen screw and turn adjustable pulley clockwise

to increase CFM. Turn counterclockwise to decrease

CFM. See figure 20. Do not exceed minimum and

maximum number of pulley turns as shown in table 5.

TABLE 5

MINIMUM AND MAXIMUM PULLEY ADJUSTMENT

Belt Min. Turns Open Maxi. Turns Open

A Section No minimum 5

E-Blower Belt Adjustment - Belt Drive

Maximum life and wear can be obtained from belts only

if proper pulley alignment and belt tension are

maintained. Tension new belts after a 24-48 hour

period of operation. This will allow belt to stretch and

seat grooves. Make sure blower and motor pulley are

aligned as shown in figure 21.

Loading...

Loading...