Page 5

506373−01 11/2011

Two−Stage Gas Valve Adjustment

Gas manifold pressures should match pressures shown

in table 3. On two stage gas valves, initiate a W2

thermostat demand to check high fire pressure before low

fire pressure. With high fire operating, reduce the

thermostat demand to W1 and check the low fire

pressure. Refer to the Unit Controller manual to initiate a

thermostat demand.

IMPORTANT − Do not set low fire pressure lower than

the certified minimum input rating listed in table 3.

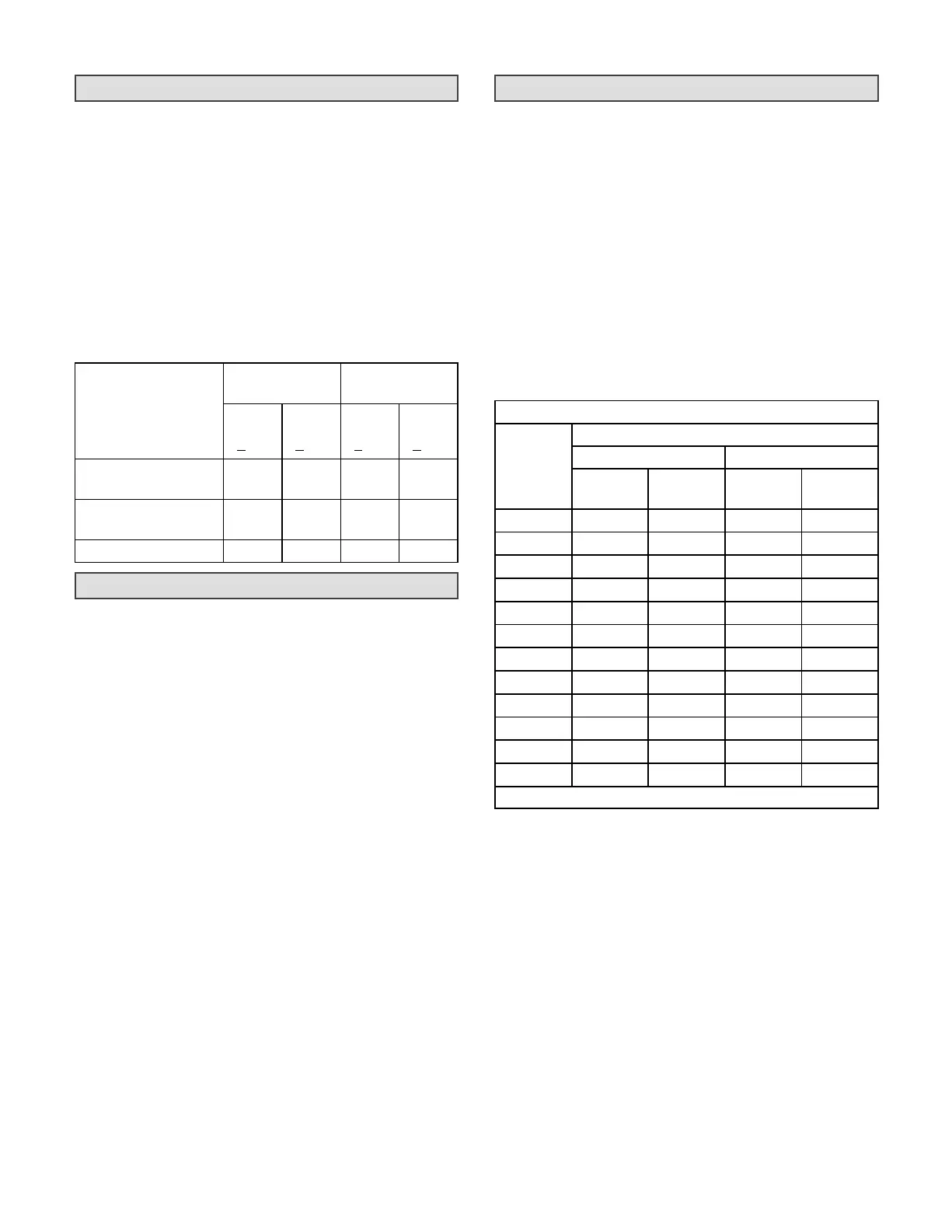

TABLE 3

MANIFOLD INPUT PRESSURES

in.wg.

Unit

Natural Gas

Propane (LP)

Gas

1st

Stage

+

0.2

2nd

Stage

+

0.3

1st

Stage

+

0.2

2nd

Stage

+

0.3

036, 048, 060, 072

Std./Med./High Heat

NA 3.5 NA 10.5

036, 048, 060, 072

Dual Heat

1.7 3.5 5.1 10.5

092− 360 1.6 3.7 5.5 10.5

Gas Heat Operation

See the operating instruction plate on the unit for details.

Proper Gas Flow (Approximate)

1− Operate unit at least 15 minutes before checking gas

flow. Determine the time in seconds for two

revolutions of gas through the meter. (Two

revolutions assures a more accurate time.) A

portable LP gas meter (17Y44) is available for LP

applications.

2− Divide the number of seconds by two and

compare to the time in table 4. If manifold pressure is

correct and rate is incorrect, check gas orifices for

proper size and restriction.

3− Remove temporary gas meter if installed.

NOTE− To obtain accurate reading, shut off all other

gas appliances connected to meter.

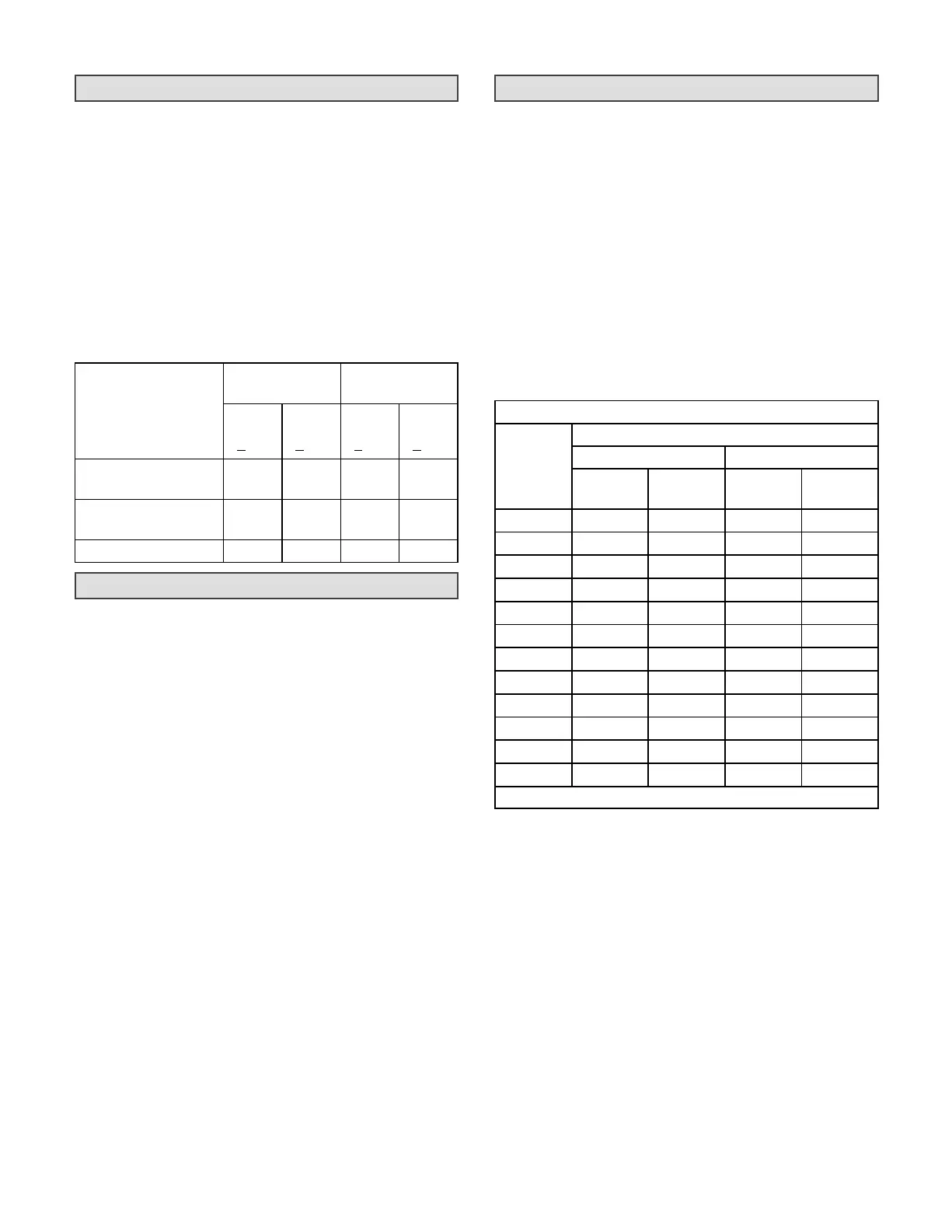

TABLE 4

GAS METER CLOCKING CHART

Unit

Input

Rate

(Btuh)

Seconds for One Revolution

Natural LP

1 cu ft

Dial

2 cu ft

Dial

1 cu ft

Dial

2 cu ft

Dial

65,000 55 111 138 277

78,000 46 92 115 231

105,000 34 69 86 171

125,000 29 58 72 144

130,000 28 55 69 138

150,000 24 48 60 120

169,000 21 43 53 107

180,000 20 40 50 100

240,000 15 30 38 75

260,000 14 28 35 69

360,000 10 20 30 50

480,000 8 15 19 38

Natural−1000 btu/cu ft LP−2500 btu/cu ft

Note: Table assumes standard temperature (60°F), pressure

(30in.Hg.), and fuel heating values (Btuh/Ft.

3

). Apply pressure

corrections in altitudes above 2000 ft.

Loading...

Loading...