Important notes

Specification of cables used

6

Basic unit wiring

6.2

6.2.7

L

6.2-5

EDS82EV903-1.0-11/2002

6.2.7 Specification of cables used

l The cables used must comply with the approvals required for the

application (e.g. UL).

l Use low-capacitance motor cables:

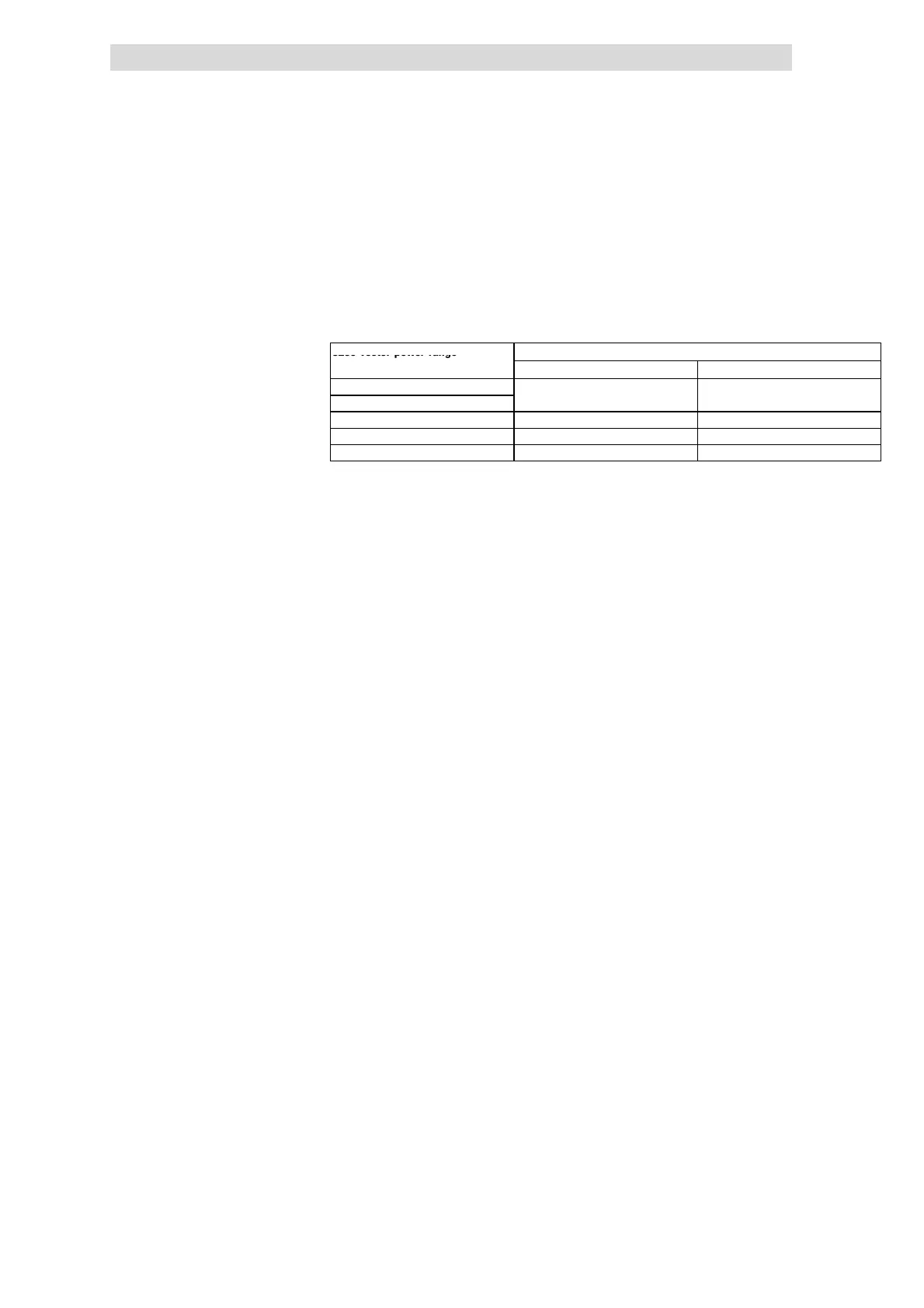

8200 vector power range Capacitance per unit length

Core/core Core/shield

0.25 ... 2.2 kW up to 1.5 mm

2

≤ 75 pF/m

3 ... 11 kW from 2.5 mm

2

≤ 100 pF/m

≤ 150 pF

m

15 ... 30 kW ≤ 140 pF/m ≤ 230 pF/m

45 ... 55 kW ≤ 190 pF/m ≤ 320 pF/m

75 ... 90 kW ≤ 250 pF/m ≤ 410 pF/m

l Max. permissible motor cable length without additional measures (if you

have to comply with EMC regulations, the permissible cable lengths can

change):

– shielded: 50 m

– unshielded: 100 m

l Control cables must always be shielded to avoid interference.

The efficiency of shielded cables is determined by

l a good shield connection

– a contact surface as large as possible

l a low resistance:

– Only use shields with tin-plated or nickel-plated copper braids!

– Shields of steel braid are not suitable.

l For the overlapping degree of the shield braid:

– Min. 70 to 80 % with overlap angle of 90°.

Power connections

Control connections

Shielded cables

Loading...

Loading...