Basic units in the power range 75 ... 90 kW

Power connections

6

Basic unit wiring

6.8

6.8.2

L

6.8-5

EDS82EV903-1.0-11/2002

l

E.l.c.bs must only be installed between mains supply and controller.

l E.l.c.bs can trip incorrectly because of

– capacitive leakage currents of the cable shields during operation

(especially with long, shielded motor cables),

– simultaneous connection of several controllers to the mains supply,

– use of additional RFI filters.

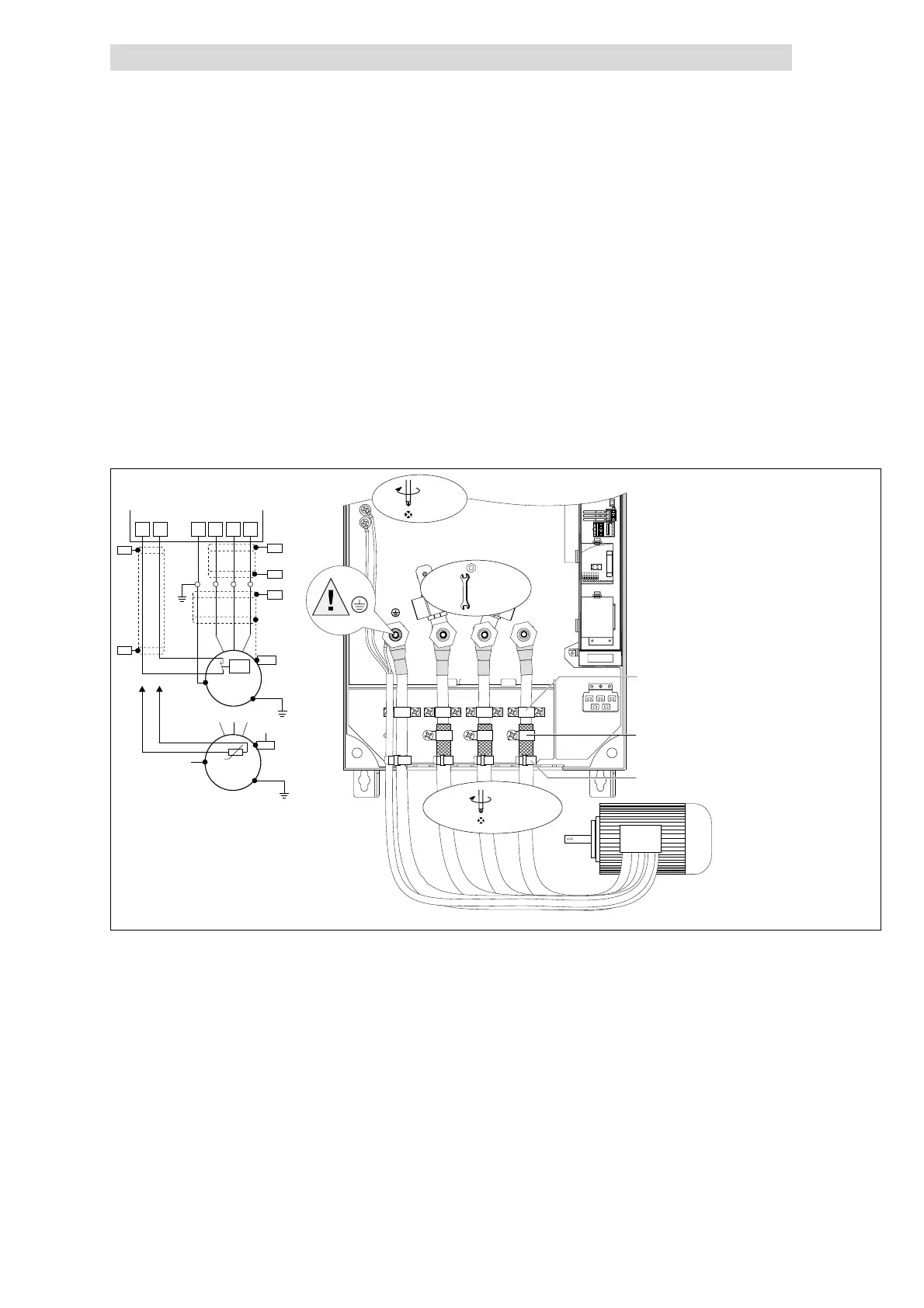

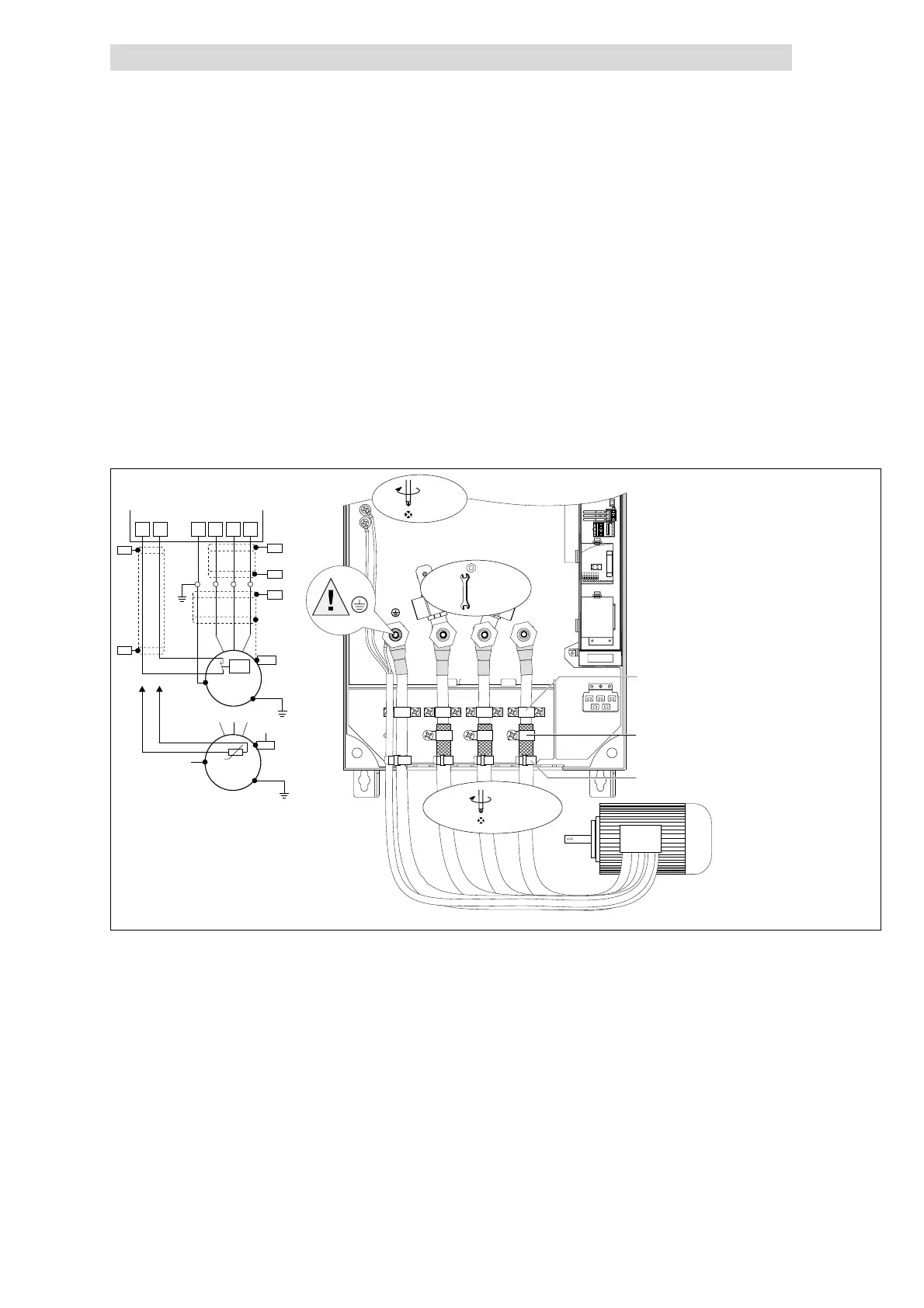

Motor connection

PE

PE

M

3~

M

3~

PTC

PE

PES

PE

U

V

W

T1

T2

ϑ>

PES

PES

PES

PES

PES

PES

T1

T2

U, V, W,

PE

30 Nm

264 lb-in

M10

U

V

W

PE

T1

T2

2,5 Nm

22,1 lb-in

2,5 Nm/22,1

3 Nm/26,5

lb-in

lb-in

M4 × 12

M5 × 12

0

1

2

PE

8200vec287

Fig. 6.8-3 Motor connection 75 ... 90 kW

0

Strain relief with cable clamps and screws M4 12 mm.

1

Connect the shields of the motor cables with the shield clamp and screws M5

12 mm to the shield sheet.

2

Additional strain relief with cable ties.

Use low-capacity motor cables! (Core/core ≤ 250 pF/m, core/shield ≤ 410

pF/m)

Use short motor cables if possible!

PES

HF-shield end by PE connection via shield clamp.

T1,

T2

Connection terminals of motor temperature monitoring with PTC thermistor or

thermal contact (NC contact).

Route a separate cable (shielded) to X2/T1 and X2/T2 for the motor

temperature monitoring.

Activate the motor temperature monitoring under C0119 (e. g. C 0119 = 1)!

Route the control and mains cables separately from the motor cable!

Please observe the following

when using e.l.c.bs:

Loading...

Loading...