Basic units in the power range 3 ... 11 kW

Connection of motor/external brake resistor

6

Basic unit wiring

6.5

6.5.4

L

6.5-6

EDS82EV903-1.0-11/2002

6.5.4 Connection of motor/external brake resistor

{ Danger!

l After the connection of a PTC thermistor or thermal contact all

control terminals only have a basic insulation (single insulating

distance).

l Protection against contact in the event of a defective insulating

distance can only be ensured by external measures (e.g.

double insulation).

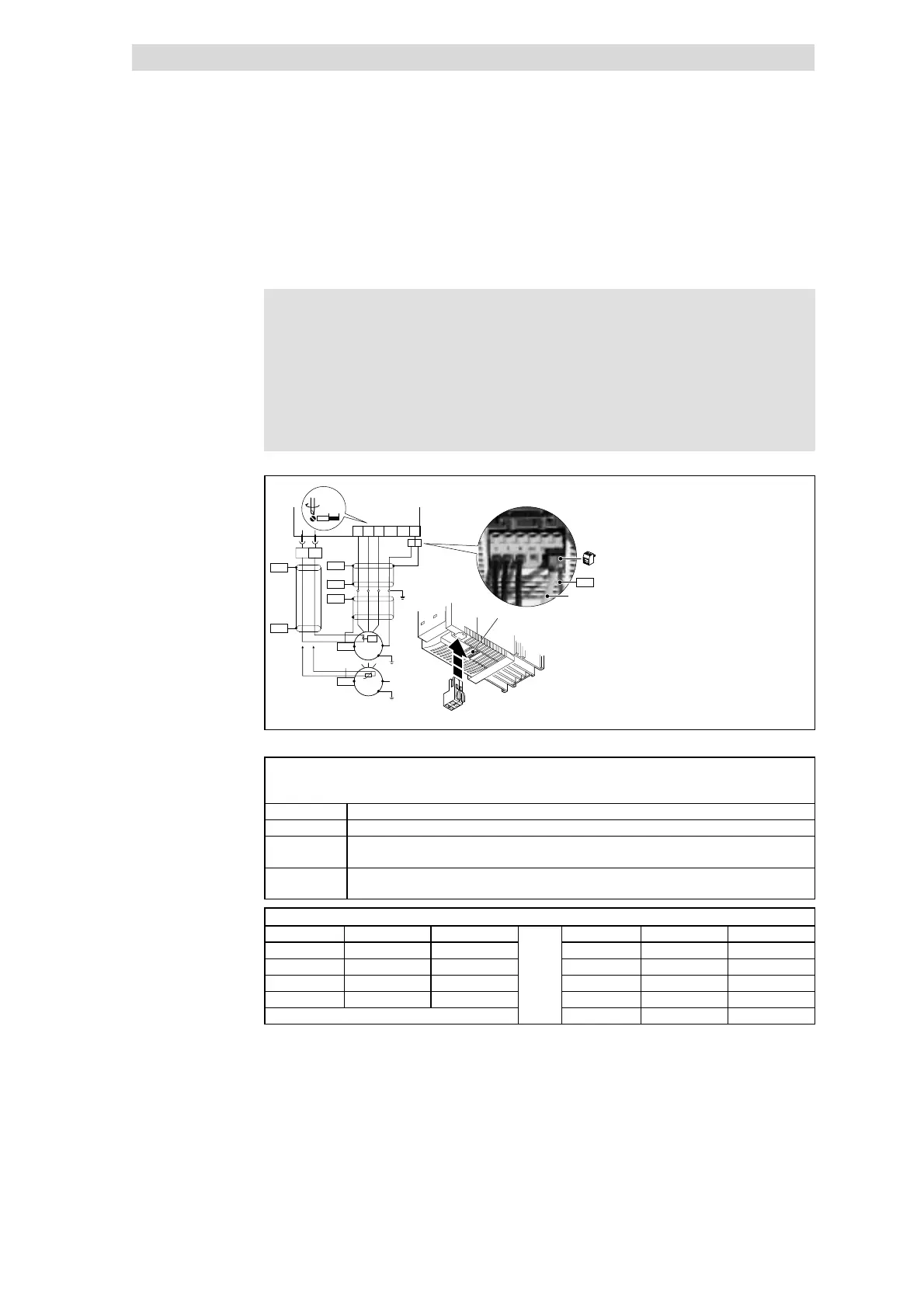

U

PES

V W

BR2

PE

PE

PE

PES

PES

PES

PES

T1 T2

M

3~

ϑ>

PES

PES

M

3~

PTC

8200 vector

X2.2

X2.1

X2.1

P

E

W

B

r

2

U

B

r

1

V

T

2

T

1

X2.2

BR1

PE

0,7...0,8 Nm

6.2...7.1 lb-in

6 mm / 0.24 in

}

PES

PE

98200vec064

Fig. 6.5-4 Motor connection 3 ... 11 kW

Use low-capacity motor cables! (core/core up to 1.5 mm

2

≤ 75 pF/m; from 2.5 mm

2

≤ 100 pF/m; core/shield

≤ 150 pF/m)

The shorter the motor cables, the better the drive response!

PES HF-shield end by PE connection through shield bracket or EMC cable connection.

X2.1/PE Earthing of the 8200 vector at the output side

X2.1/BR1,

X2.1/BR2

Connection terminals for the brake resistor

(For information about the operation with brake resistor see the Operating Instructions)

X2.2/T1,

X2.2/T2

Connection terminals motor temperature monitoring through PTC thermistors or thermal contacts

Activate motor temperature monitoring under C0119 (e. g. C0119 = 1)!

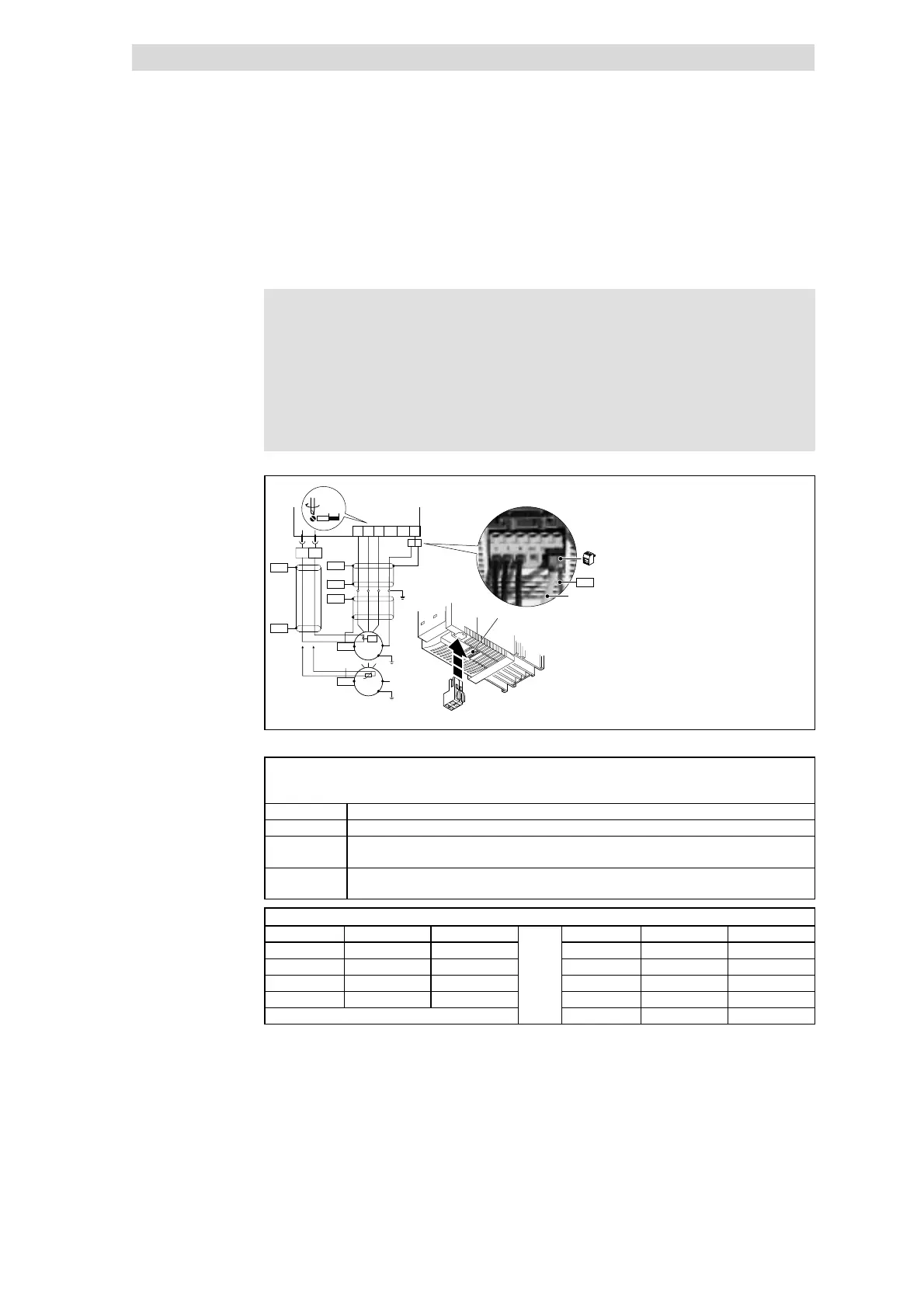

Cable cross-sections U, V, W, PE

Type mm

2

AWG Type mm

2

AWG

E82EV302K2C 2.5 12 E82EV302K4C 1 16

E82EV402K2C 4 10 E82EV402K4C 1.5 14

E82EV552K2C 6 10 E82EV552K4C 2.5 12

E82EV752K2C 6 10 E82EV752K4C 4 10

E82EV113K4C 4 10

8200 vector 3 ... 11 kW

Loading...

Loading...