Pressure control

15

Application examples

15.2

L

15.2-3

EDS82EV903-1.0-11/2002

Application-specific configuration

l

Motor parameter identification. (¶ 10.9-1)

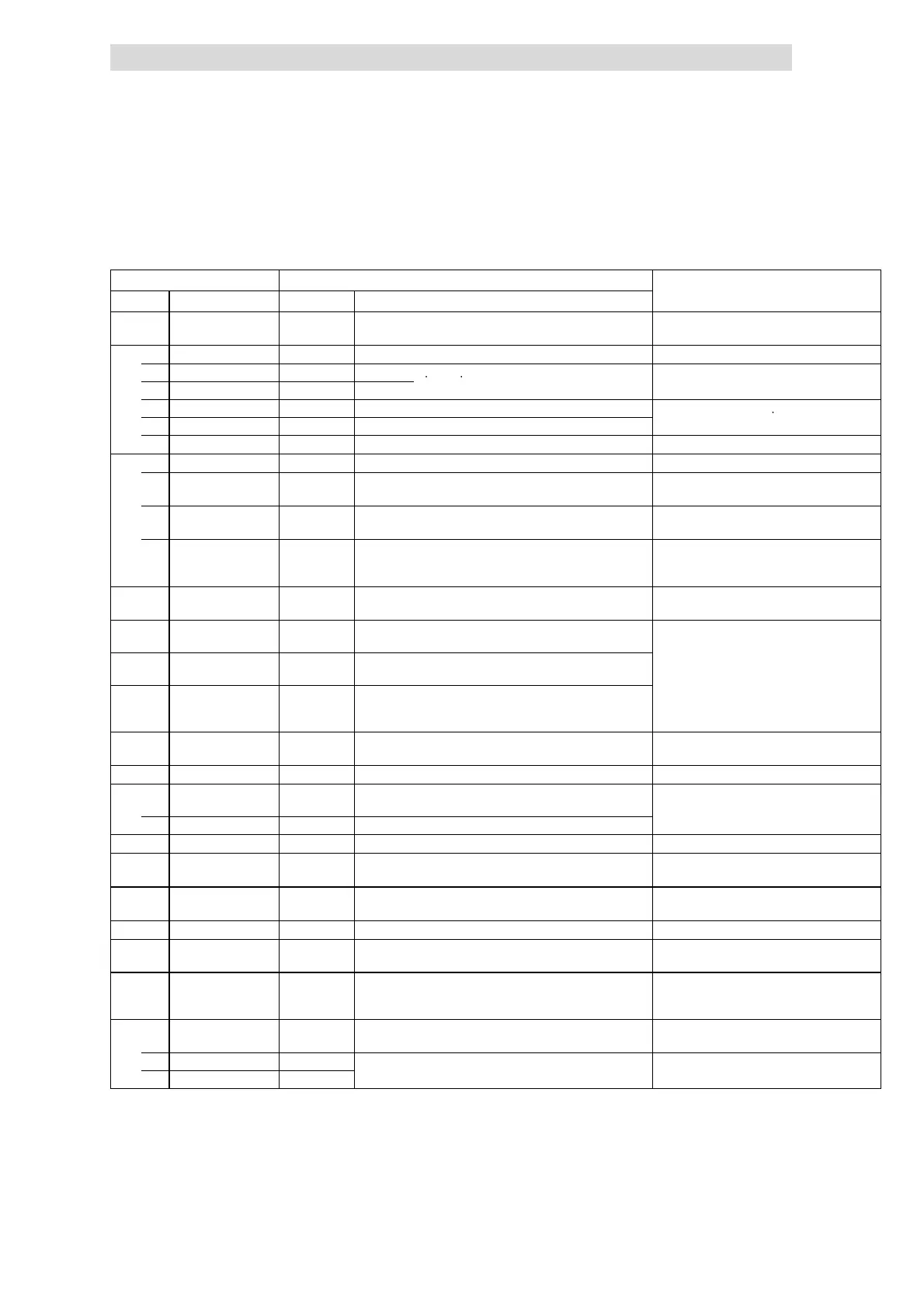

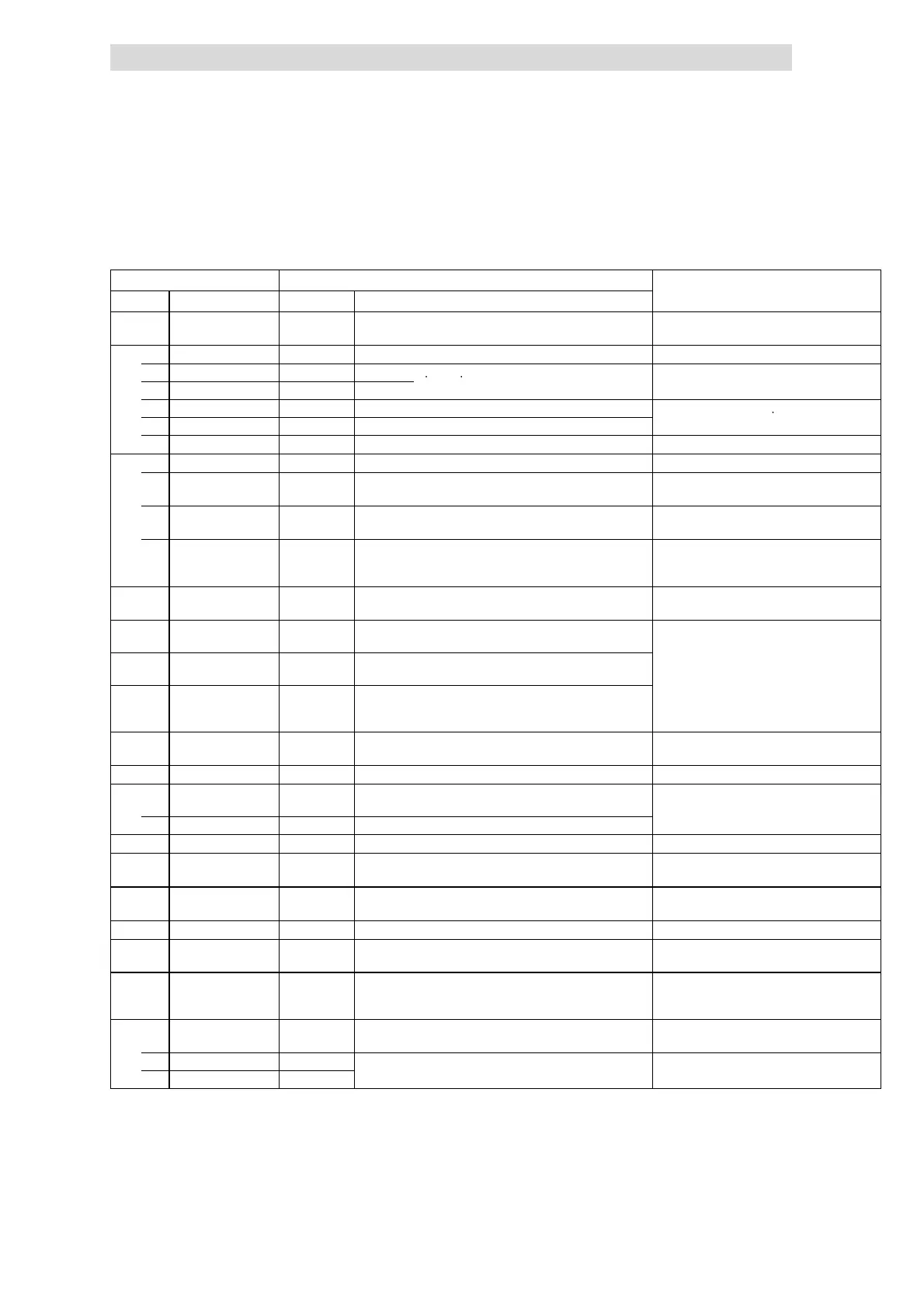

Code Settings IMPORTANT

No. Name Value Meaning

C0014 Operating mode 3 V/f characteristic control V ~ f Square-law characteristic with constant V

min

boost

C0410 Digital signals source

8 DOWN 1 E1

Inputs of pushbuttons “UP” and “DOWN”

7 UP 2 E2

1 JOG1/3 3 E3 JOG speed for night reduction

Activation of the JOG speed deactivates the

19 PCTRL1-OFF 3 E3 Process controller deactivation

process controller.

17 M/Re 4 E4 Changeover PLC/setting up operation at site

C0412 Analog signal source

1 Setpoint 1

(NSET1-N1)

1 X3/2I Pressure setpoint (manual)

2 Setpoint 2

(NSET1-N2)

3 MPOT1-OUT Motor potentiometer function Pressure setpoint (remote)

5 Act. process

controller value

(PCTRL1-ACT)

4 X3/1U Actual pressure value

C0145 Process controller

setpoint source

0 Total setpoint (PCTRL1-SET3) Main setpoint + additional setpoint

C0070 Process controller

gain

à

If necessary, adapt to process

à More information: ^ 10.10-1 ff.

C0071 Process controller

readjust me nt time

à

C0072 Differential

component of

process controller

à

C0074 Process controller

influence

100.0 0.0 {0.1 %} 100.0

C0238 Frequency precontrol -0- -0- No precontrol (only process controller) Process controller has full influence

C0419 Free configuration of

analog outputs

Analog signal source

1 X3/62 (AOUT1-IN) 8 Actual process controller value

C0037 JOG1 17 Derating to approx. 1/3 of rated motor speed

C0239 Minimum frequency

limitation

10.00 Setpoint-independent minimum speed

C0182 Integration time

S-ramps

0.50 s Smooth start

C0625 Skip frequency 1 30.00 Hz

C0628 Bandwidth of skip

frequencies

10.00 % ref. t o C0625

C0119 Configuration PTC

input/earth fault

detection

4 PTC input active, TRIP set

C0415 Free configuration of

digital outputs

1 Relay output K1 16 Ready for operation

2 Digital output X3/A1 25 Trip error message

Loading...

Loading...