- 36 -

9LD Workshop Manual _ cod. 1.5302.286 - 3° ed_rev. 02

4

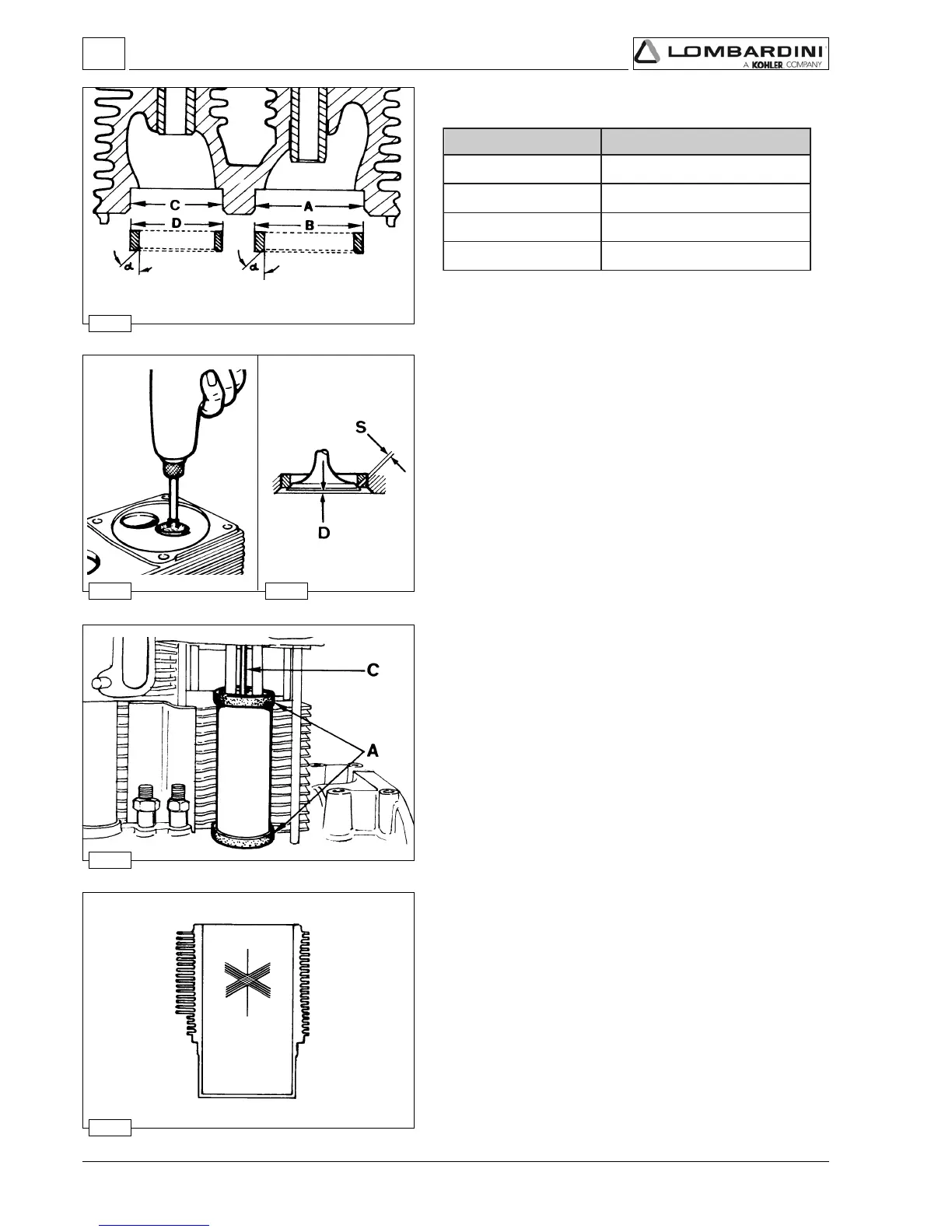

A

610.04÷000.04

B

590.04÷180.04

C

610.43÷000.43

D

590.43÷180.43

40

41

43

42

44

125° ÷ 135°

Disassembly / Reassembly

Valve seats and housings

Press valve seats into the housings and cut at 45°.

INTAKE

VALVE

EXHAUST

VALVE

Ref.

Dimensions (mm)

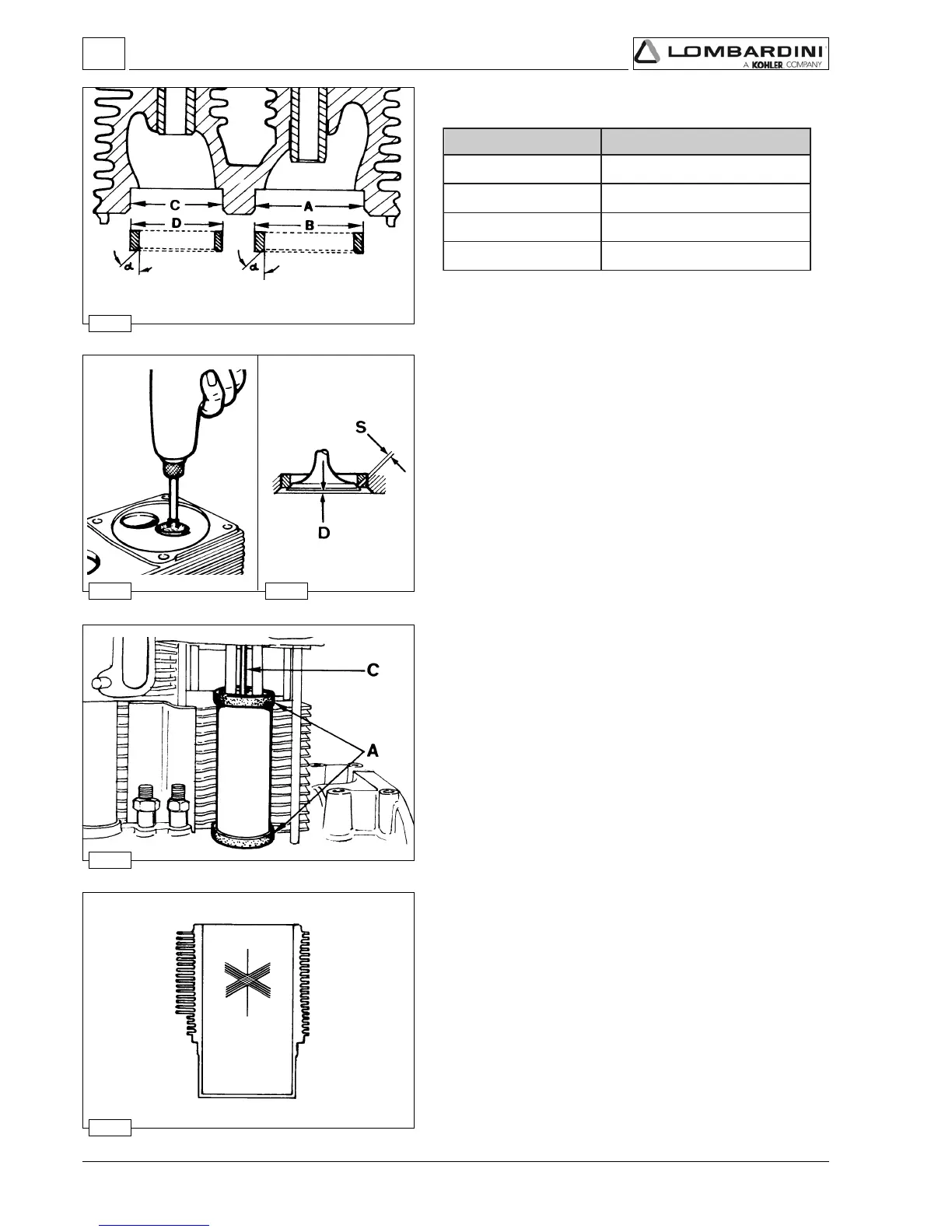

Pushrod tube

When refitting cheek that gaskets A and rocker arm lubricatíon tube C

are well inside their seats.

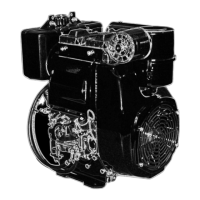

Valve seat grinding

After cutting grind valve seats with fine emery paste in oil suspension.

The sealing surface S should not exceed 2 mm.

Valve recess after grinding D = 0.75÷1.25 mm; maximum worn limit

1.65 mm.

CYLINDER

Checks and cylinder roughness

Fins must be intact.

Cross hatch pattern must range between 125°÷135°: they must be

uniform and clear in both directions.

Average roughness should range between 0.35 and 0.60 µm.

Loading...

Loading...