- 65 -

9LD Workshop Manual _ cod. 1.5302.286 - 3° ed_rev. 02

6

144

145

146

Fuel system

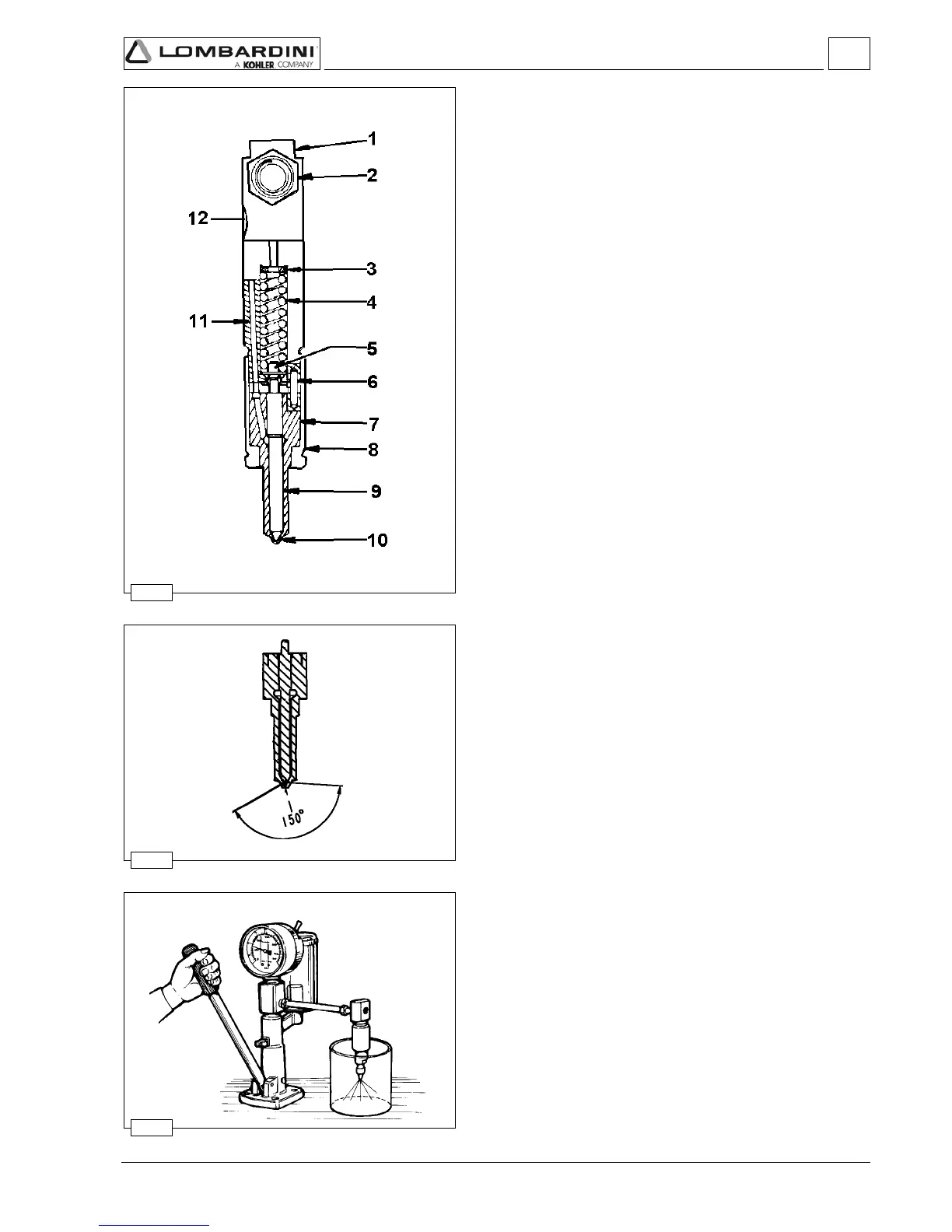

Size P injector, for 97/68 CE and EPA engines

Components:

1 Injector housing

2 Intake fitting

3 Shim

4 Spring

5 Pressure rod

6 Taper pin

7 Nozzle

8 Cup

9 Needle valve

10 Sump

11 System duct

12 Overflow pipe

Injector setting

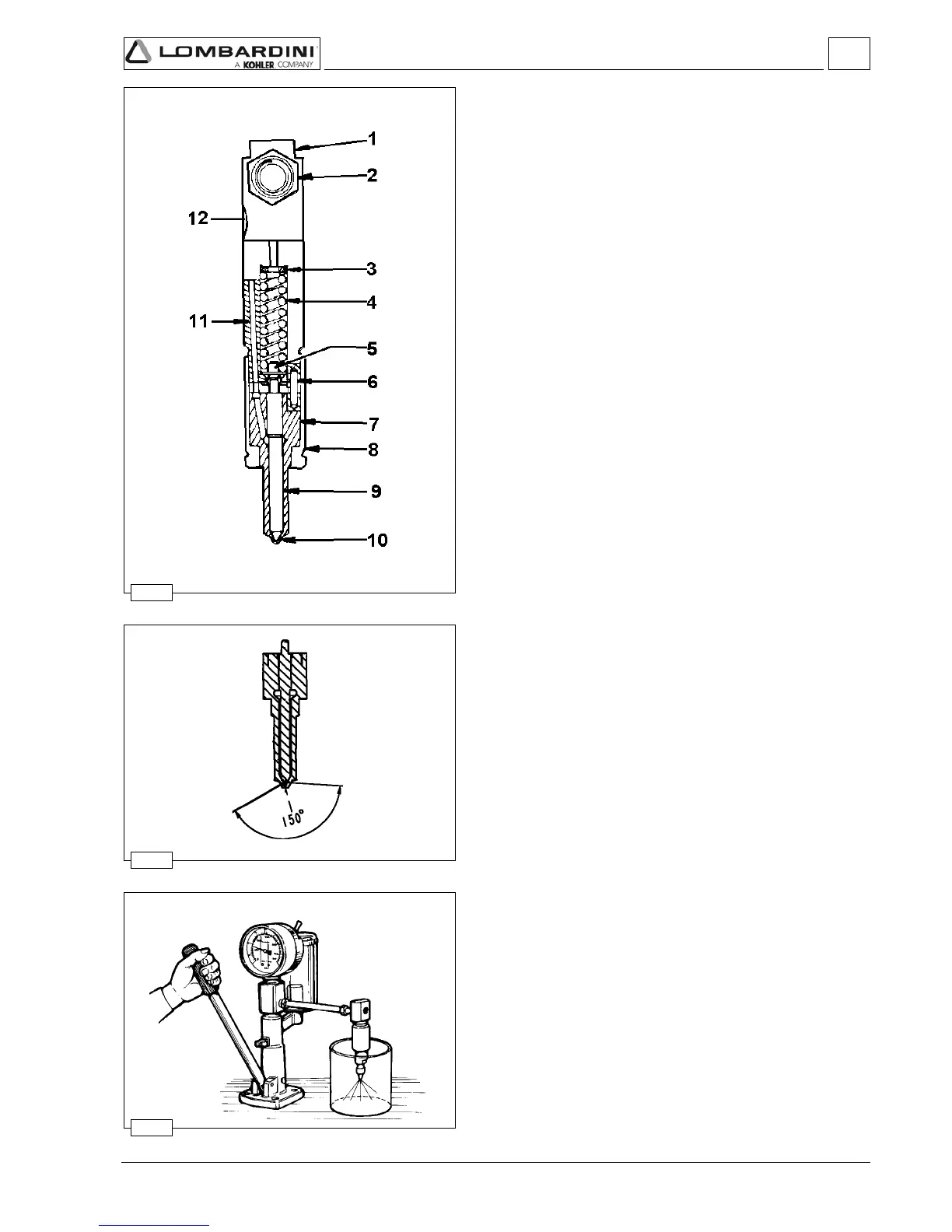

Connect the injector to a diesel injector calibration pump.

Check needle valve sealing by slowly moving hand pump until

approximately 180 bar and maintain this pressure for 10 seconds.

Chek that setting pressure is 210 ÷220 bar for standard engines (245 ÷

230 bar for EPA e CE engines); make the required adjustments, if any,

by modifying the adjusting shim height.

When replacing the spring, setting should be performed at a 10 bar

greater pressure (255÷265 bar) to allow for bedding during operation.

Replace nozzle in case of dripping.

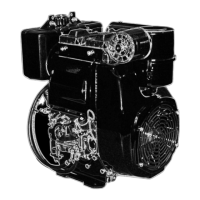

Size P nozzle, for 97/68 CE and EPA engines

Features:

Hole number and diameter ............. 5 x 0.23 mm.

Jet angles ....................................... 150°.

Needle valve elevation .................... 0.200 ÷ 0.205 mm

Clean nozzle tip with a brass brush.

Check that holes are not obstructed using a mandrel with steel wìre

with 0.23 mm diam.

When refitting tighten ring nut at 42 ÷ 48 Nm.

Loading...

Loading...