- 38 -

9LD Workshop Manual _ cod. 1.5302.286 - 3° ed_rev. 02

4

A

°1

mm56.0÷mm04.0

°2

mm56.0÷mm04.0

°3

mm06.0÷mm03.0

A

11,0÷70,002,0

B

90,0÷50,061,0

C

80,0÷40,051,0

50

51

53

52

49

Disassembly / Reassembly

Chromium-plated ring

To rs io n al in te rn al ta pe re d

ring

Oil control ring

Limit value

(mm)

Dimensions

(mm)

Ref.

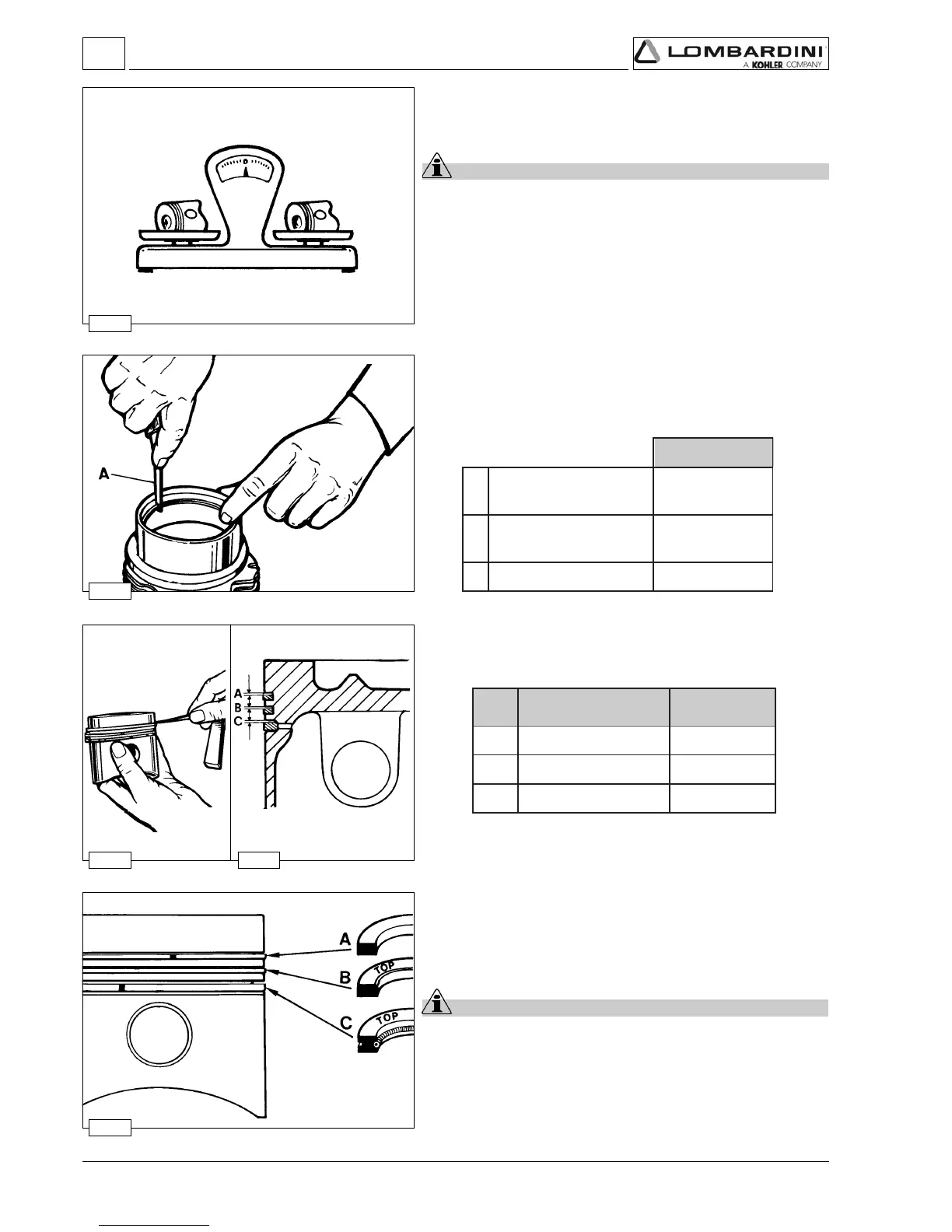

Piston rings - Fitting sequence

A = 1° Chromium-plated ring

B = 2° Torsional (internal tapered) ring

C = 3° Oil control ring

Important

Before fitting the piston into the cylinder stagger the ring gaps at

120°.

Pistons ringis - Clearance between grooves (mm)

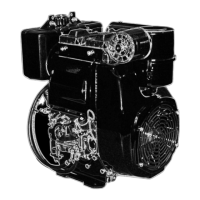

Piston rings - End gaps (mm)

Place piston rings squarely into the unworn part of the lower cylinder

and measure the end gap.

Piston weight

Weigh pistons when replacing them in order to avoid unbalance.

Important

The difference in weight should not exceed 6 g.

Loading...

Loading...