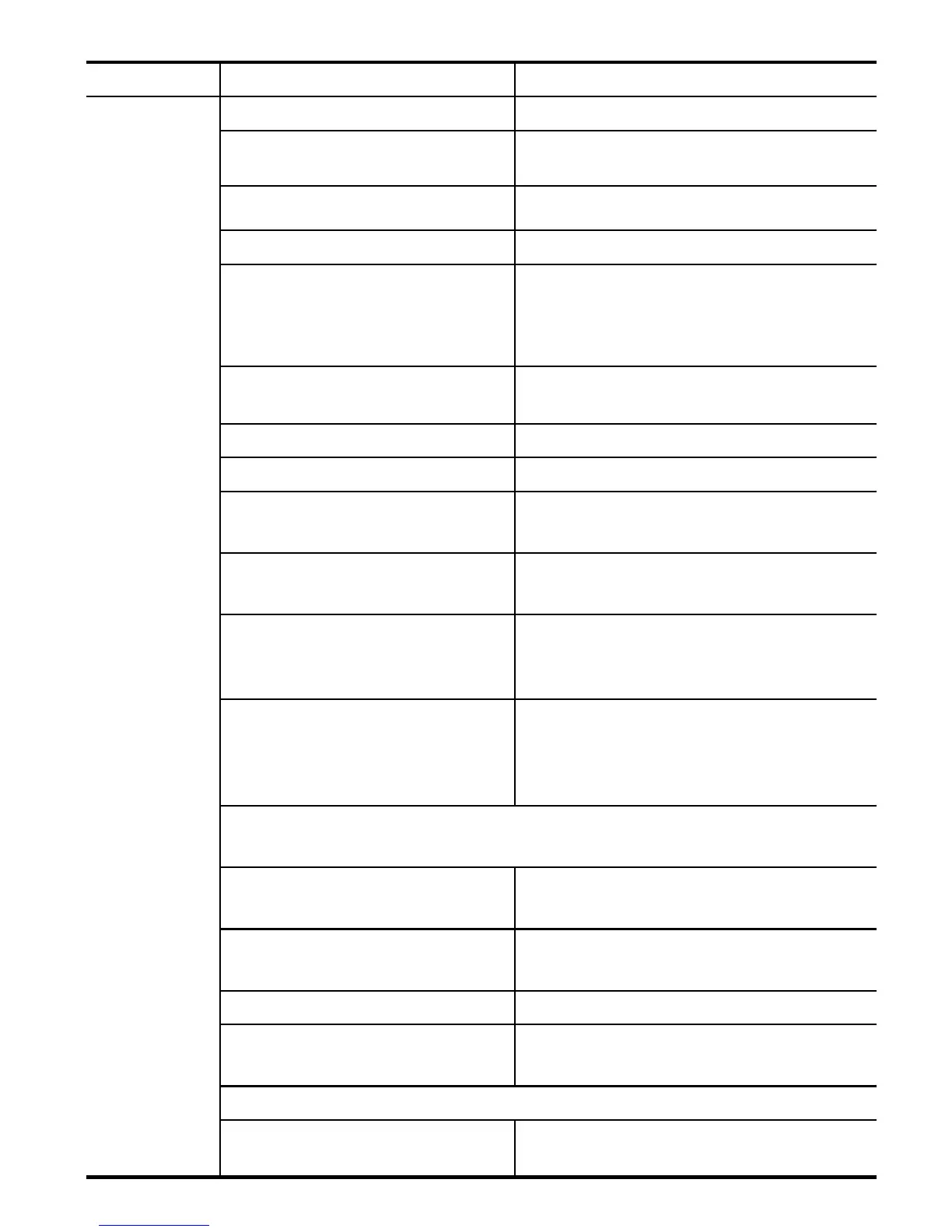

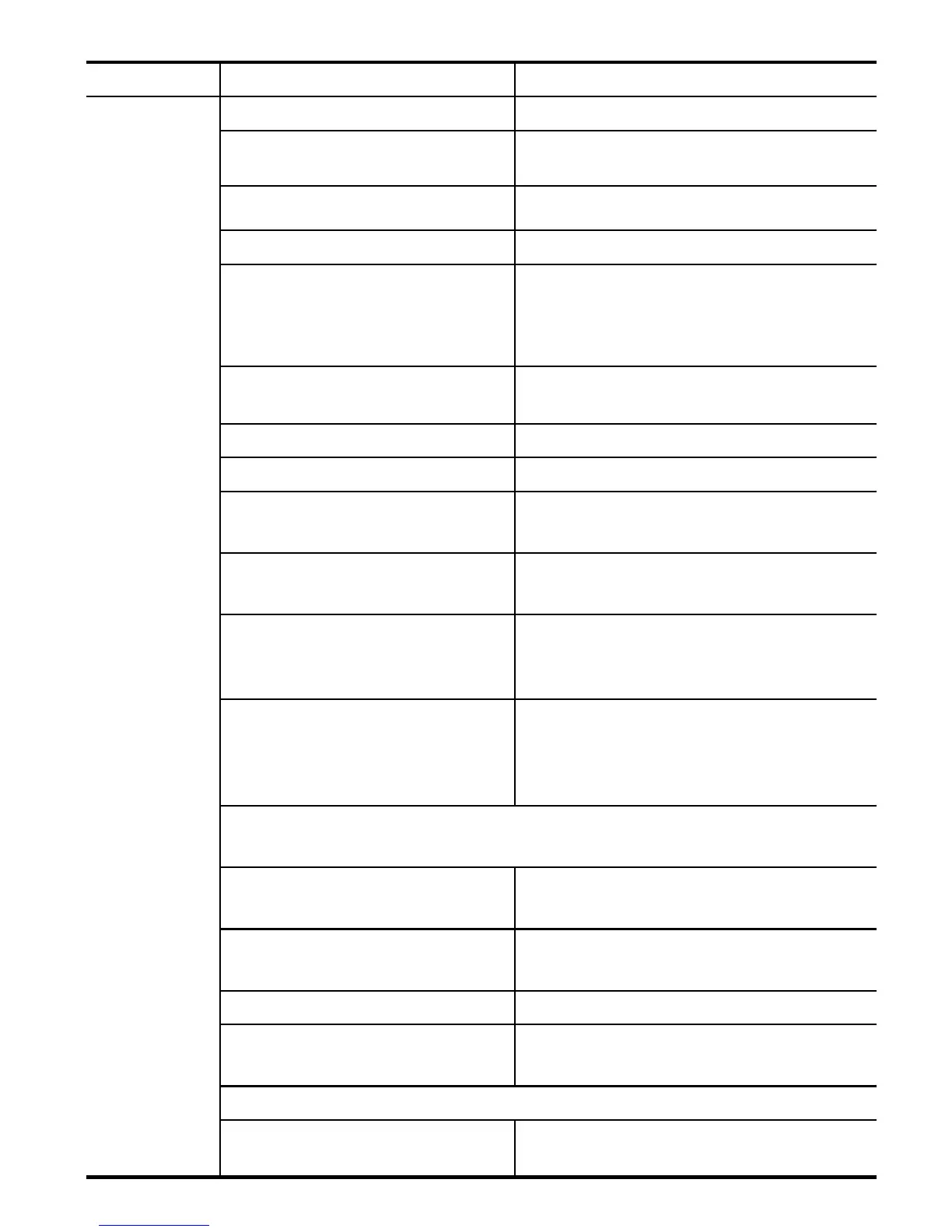

SECTION 6. TROUBLESHOOTING

14)Broken slow-return check valve

Disassemble and wash spool clean.

If it is damaged seriously,replace it as an

assembly.If damage is minor,correct surface

with oil stone and finish by lapping.

12)Broken flow divider

(Stuck sequential valve spool)

Inspect cylinder and valves.Replace

damaged seals,and repair.

(Check each part systematically)

11)Excessive internal leaks

Readjust.

(Cracking:refer to the specifications)

10)Maladjusted relief valve

As it will cause oil leaks or internal

wear,replace with gear oil of SAE80

9) Too low viscosity of

transmission oil

Replace8) Broken cylinder

Decrease load7) Excessive load on lift

Inspect,adjust,repair,or replace if

necessary.(Refer to section 3)

6) Poor link mechanism

Inspection pump and repair or replace if

necessary.Pay particular attention to shaft

seal because a broken seal sometimes

intakes air.

5) Broken or poor hydraulic pump

Clean.4) Clogged suction filter

Tighten securely or replace broken parts.

3) Air taken in through suction

Maintain oil level by replenishing with the

same kind of oil

2) Insufficient transmission oil

Raise engine speed slightly1) Insufficient engine speed1.Lift does

not rise

Clean them with compressed air or a sharp

point.

②Clogged orifices or slanted

orifices in pilot passage.

Lap after repairing flaws with oil stone①Stuck compensator plunger

(unloading valve 1)

13)Broken control valve

(Even when spool is shifted to up position,lift does not rise)

Lap after disassembling,cleaning, and

repairing flaws with oil stone

①Stuck poppet

Lap after repairing flaws with oil stone④Bitten or stuck check valve

plunger

Correct minor flaws with oil stone③Stuck poppet(unloading valve 2)

CountermeasuresCausesProblems

9-29

Loading...

Loading...