3.POWER TRAIN DIAGRAMS

Refer to page 5-49 and 50 at the end of this chapter.

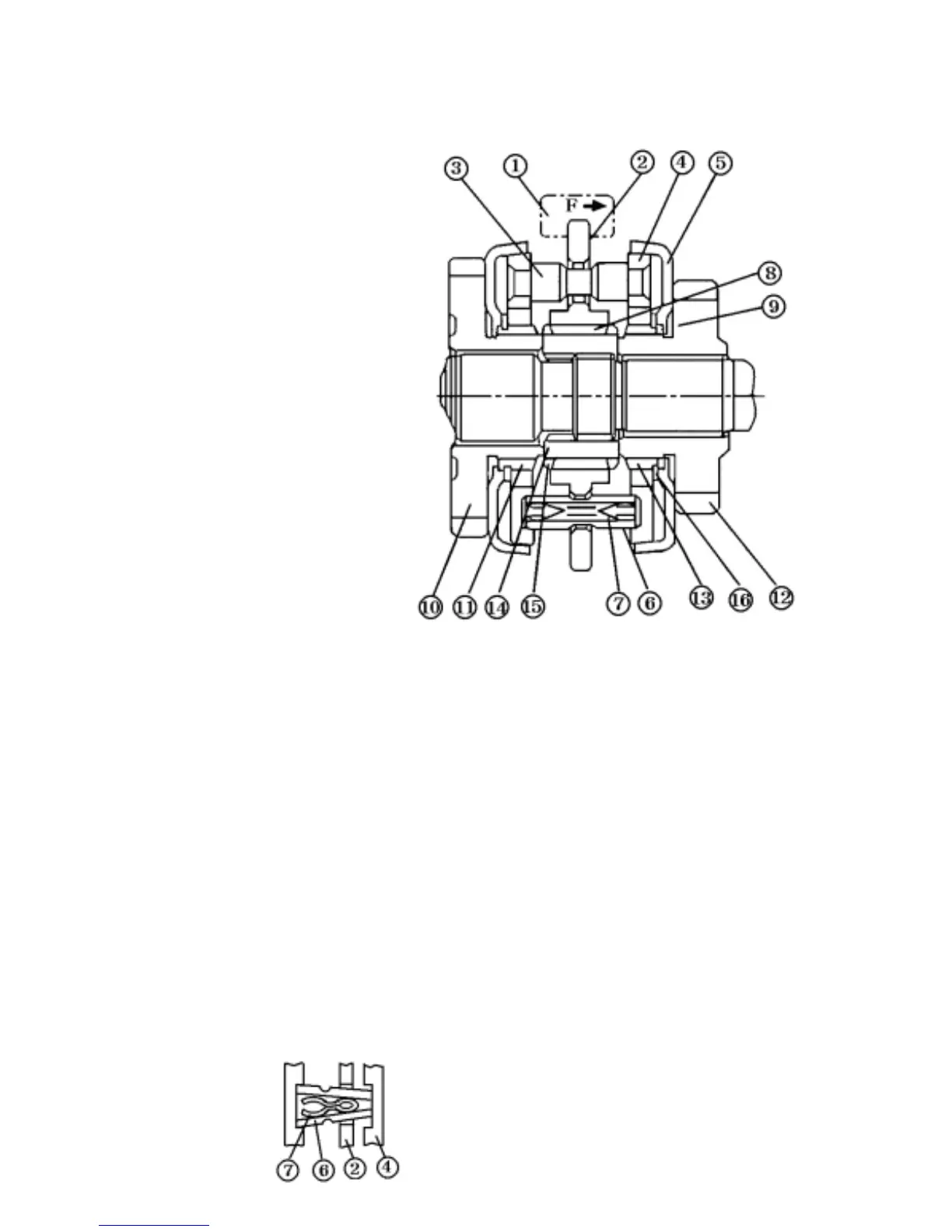

4.CONSTRUCTION AND FUNCTION OF THE SYNCHROMESH MECHANISM

①Shifter

②Hub

③Block pin

④Synchro-ring

⑤Synchro-cup

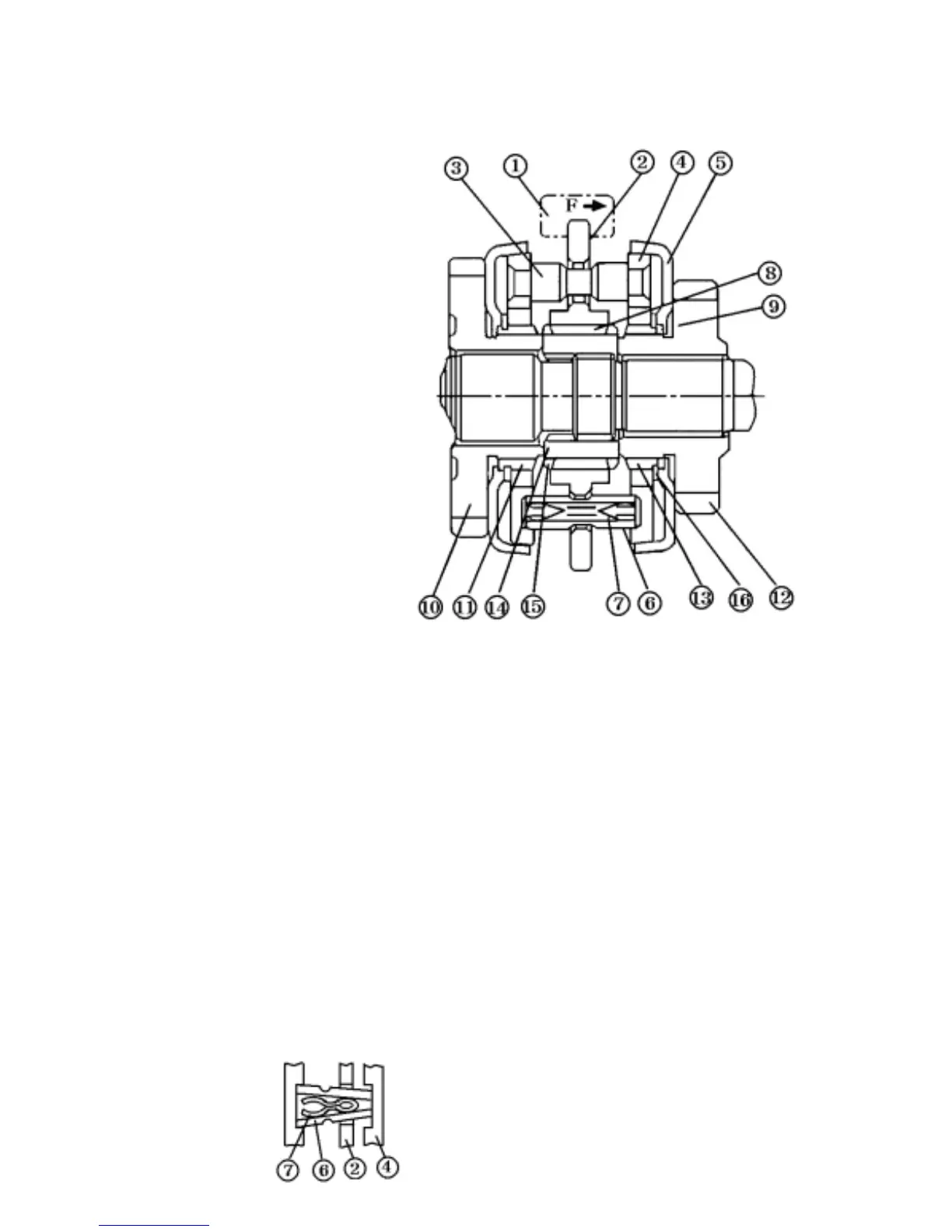

⑥Thrust piece

⑦spring

⑧spline of hub(2)

⑨spline of synchro-cup(2)

⑩constant mesh gear

⑪spline of gear(10)

⑫constant mesh gear

⑬Spline of gear(12)

⑭Spline hub

⑮Spline of spline hub(14)

16.Snap ring C(for shaft)

Fig.5-2 Synchromesh

2)The synchromesh mechanism includes the

components staged below

(1)Synchro-hub

The synchro-hub is composed of the hub(2),

block pin(3),synchro-ring(4),thrust piece(6),and

spring(7).Synchro-ring(4)has a conical friction

surface on its circumstance.Block pin(3)

prevents hub(2) from sliding until the torque,

imposed upon the pin due to the speed

differential caused when shifting gears,disappears.

Thrust piece(6)is composed of an outer split pin

and an inner and is held together as one unit by

the expansion force

of the spring.

It has a tapered

shape as shown

in Fig.5-15

when the hub is position to side and also

serves as a lock pin to keep the synchro

mechanism engage.

(2) Synchro-cup

It has a conicial friction surface which forms a

pair with synchro-ring(4).It meshes with the

gears(10) and (11) through the splined part.

3)Function principles(operating procedures)

The synchromesh mechanism operates in the 4

stages mentioned below to complete the

transmission from NEUTRAL to

ENGAGEMENT

5-2

Loading...

Loading...