(2)Inspection of sleeve

Ensure smooth movement of the sleeve.If it

does not move smoothly,clean and grease it.

Use heat-proof grease.

(3) Inspection of tension springs.

If there are some broken tension springs,

replace them.

(4) Inspection of the fork.

Inspect the contact faces of the fork and the

sleeve.If there is abnormal wear,make

repairs or replace the fork or the sleeve.

(5) Inspection of the clutch shaft.

The clutch shaft must be revolve smoothly

3) Reassembly

Reassemble the disassembled parts in reverse

order of disassembly,pursuant to the following

instructions.

(1) Each sliding part should be coated with

heat-proof grease.

(2) The clutch fork taper pin should be locked

securely with wire.

(3) Smooth movement of each part should be

conformed.

(4) The release bearing must be installed in the

correct direction.

2.CLUTCH SHAFT AND RELATED PARTS.

1) disassembly

(1) Remove the tension spring and extract the

sleeve

(2) Remove the wire which is retaining the

taper pin.

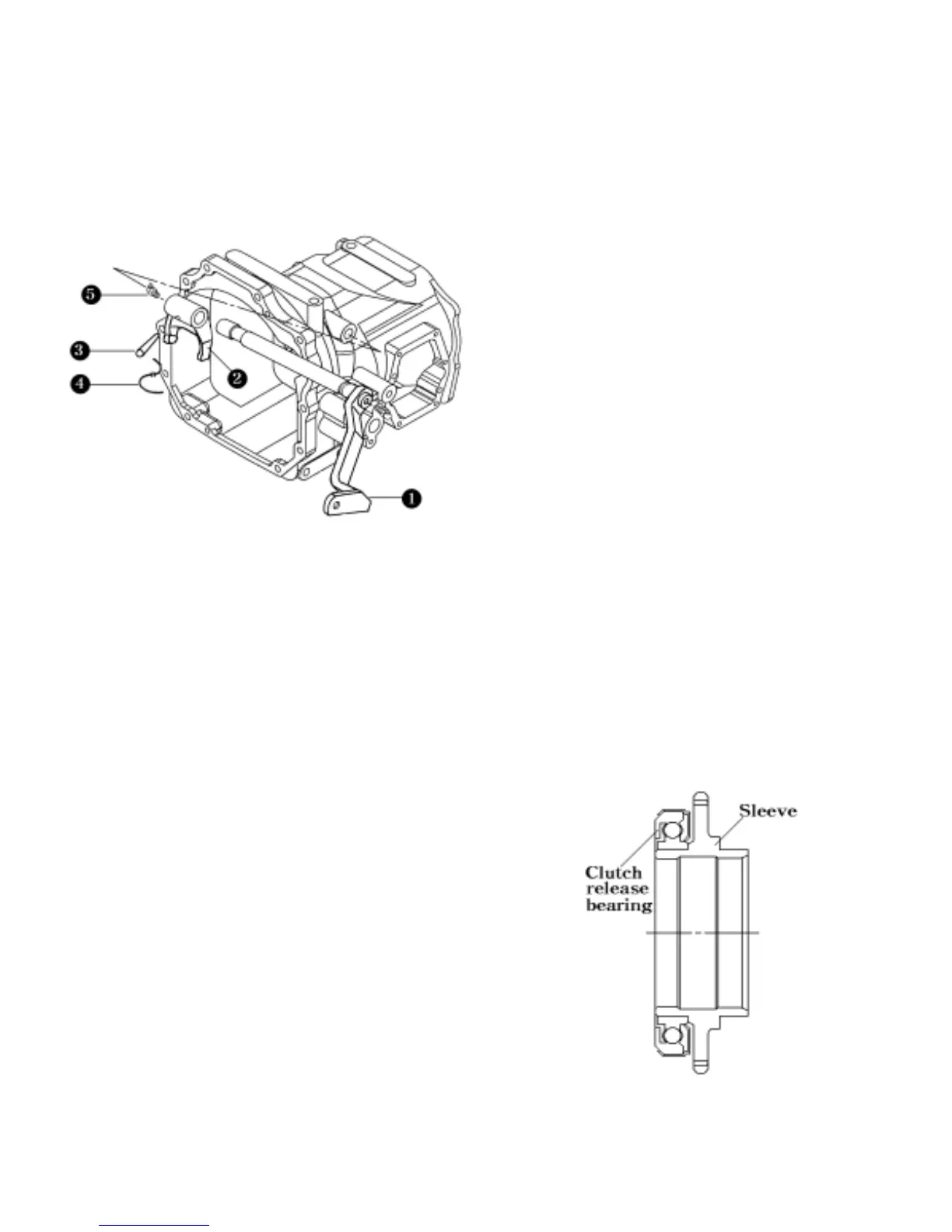

①Clutch shaft comp ②Release fork

③Taper pin ④Wire ⑤Grease fitting

Fig4-8 Main clutch and related parts

(3)Remove the grease fittings from the clutch

shaft ends.

(4)Turn the release fork upward and pull out

the taper pin.Then draw the clutch shaft.

2) Inspection

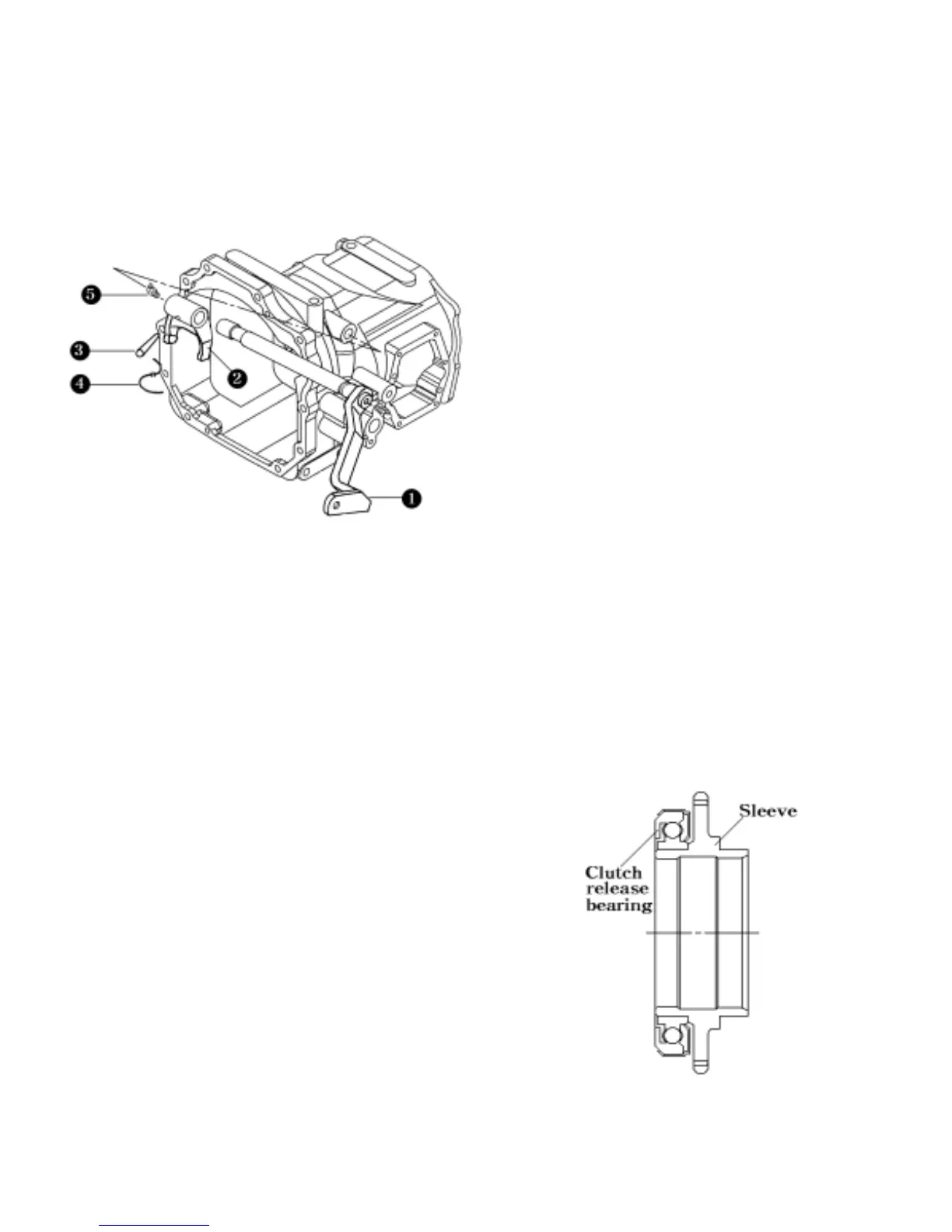

(1)Inspection of release bearing

The release bearing is of the grease-sealed

type,but when the grease in the bearing

reaches a low level or the bearing does

not turn smoothly due to damage or seizure,

replace the bearing.

Note:

The release bearing should not be washed.

Fig 4-9 Release bearing

4-5

Loading...

Loading...