National Crane 1-21-2019 Control # 104-07 6-9

1400A SERVICE MANUAL SWING

Torque wrenches are precision instruments and must be

handled with care. To ensure accuracy, calibrations must be

made on a scheduled basis. Whenever there is a possibility

that a torque wrench may have been either overstressed or

damaged, it should immediately be removed from service

until re-calibrated. When using a torque wrench, any erratic

or jerking motion can result in the application of excessive or

improper torque. ALWAYS use a slow, even movement and

STOP when the predetermined value has been reached.

If it is reported by the crane operator or suspected that the

crane has been overloaded beyond the capacities specified

above the bold line on the cranes’ capacity chart, then all

swing bearing bolts must be inspected for looseness and

re-torqued to specifications.

Torque the swing bearing bolts according to the procedures

outlined in this section.

When using step wrenches, calculated wrench settings are

valid only when the following conditions are met.

1. Torque wrenches must be those specified and forces

must be applied at the handle grip. The use of handle

extensions will change applied torque to the bolt.

2. All handles must be parallel to the step wrench during

final tightening. Multiplier reaction bars may be

misaligned no more than 30 degrees without causing

serious error in torque.

3. Multiplier bar handles must be propped or supported

within the outer 1/4 of the handle length, or serious

under or over tightening will occur.

Swing Bearing Bolts

The inner race of the bearing is secured to the turret by 36,

7/8 inch Grade 8 bolts (Figure 6-5). The outer race of the

bearing is secured to the carrier frame by 32, 3/4 inch, Grade

8 bolts (Figure 6-5).

Torque Values

Torque all swing bearing bolts to a final torque: Fasteners

and Torque Values on page 1-7.

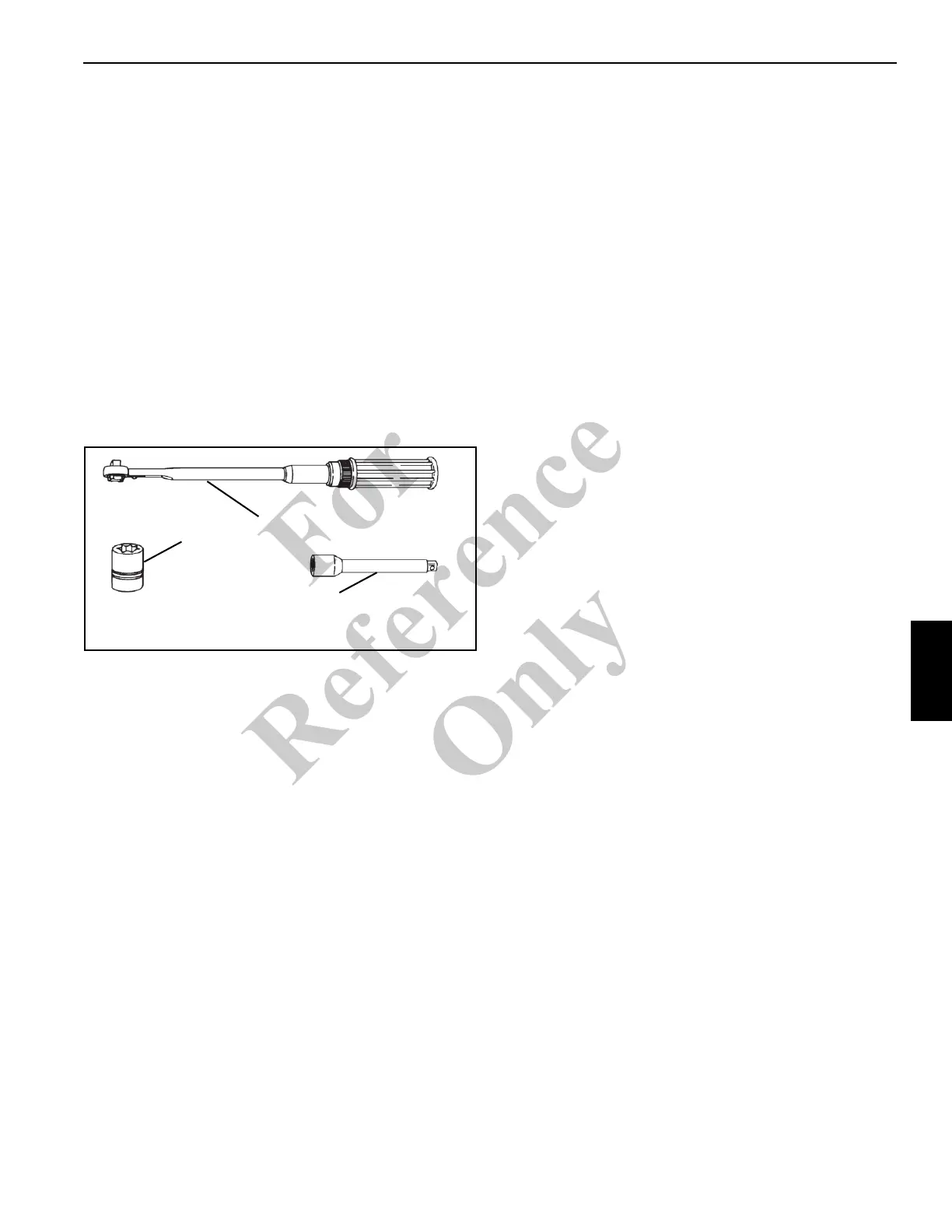

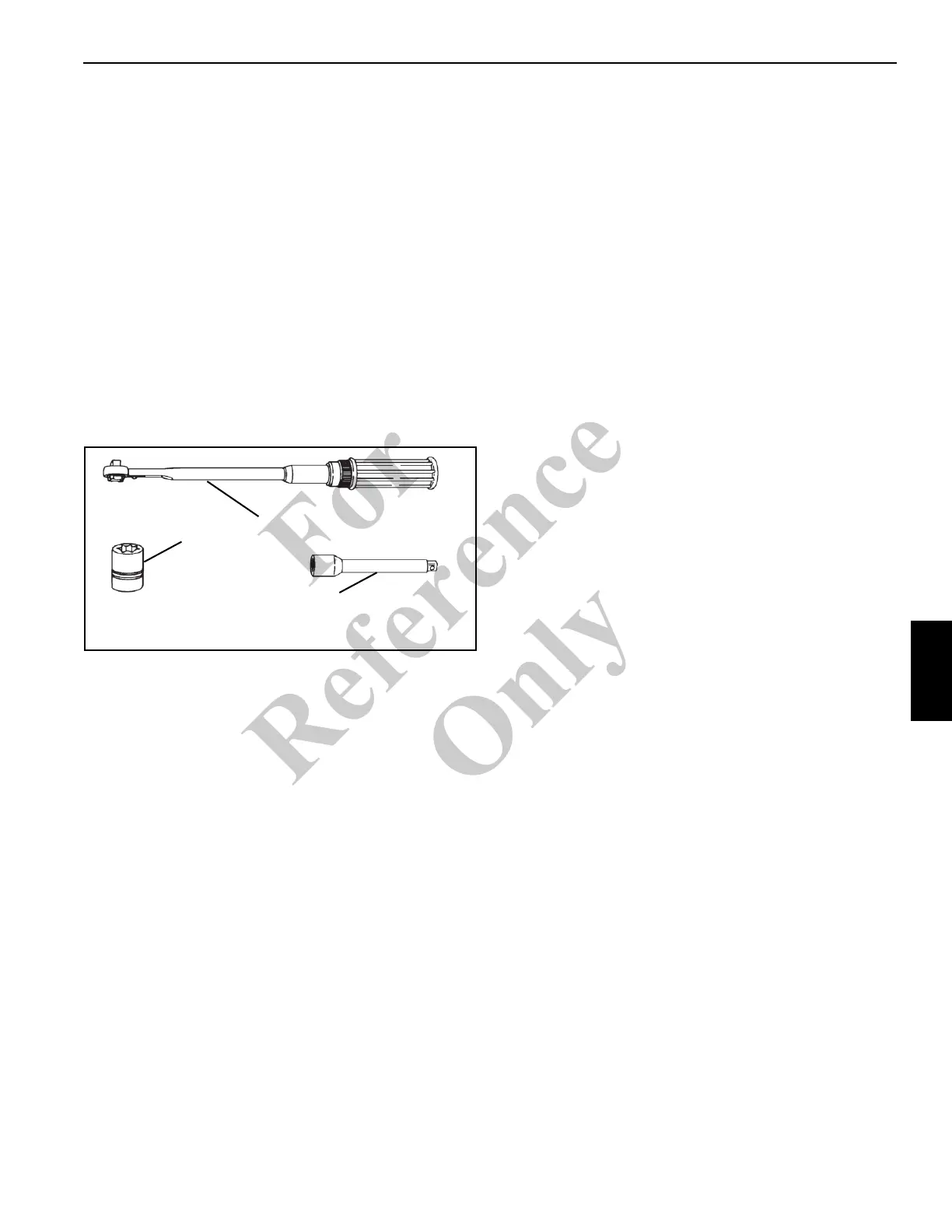

Tools Required

A complete set of special tools required to torque the swing

bearing bolts is listed and shown in (Figure 6-4).

Inner Race Torquing

The inner race bolts can be accessed through the access

holes underneath the bed (Figure 6-6).

1. Extend and set the outriggers. Fully elevate the boom.

2. Torque eight bolts (Figure 6-5) to 637 Nm ±27 Nm (470

lb-ft ± 20 lb-ft) using the following sequence pattern; 1,

19, 10, 28, 6, 23, 15, and 33. Tools used are the socket,

multiplier, backlash adapter, necessary extensions, and

torque wrench.

3. Return to bolt 1 and torque all bolts sequentially in a

clockwise direction to the final torque:

Fasteners and

Torque Values on page 1-7. The same tools are used as

in step 1.

FIGURE 6-4

Torque Wrench 3/4 inch Drive

3/4 and 7/8 inch

sockets

Extension

Fo

r

Reference

Only

Loading...

Loading...