National Crane 1-21-2019 Control # 104-07 6-13

1400A SERVICE MANUAL SWING

13. Remove the remaining bolts and washers securing the

swing bearing outer race to the carrier.

14. Carefully lift the turret and set it on blocking that will not

allow the turret to tilt or shift. Leave the lifting device

attached.

NOTE: If the current bearing is to be reinstalled, mark the

position of the bearing on the turret before removal.

15. Remove the 36 bolts from the inner race of the turret

bearing.

16. Lift the turret off the swing bearing and set on blocking.

NOTE: The bearing weighs about 284 kg (625 lb).

Check the bearing teeth for chipping or cracking. If any

evidence of these is found, replace the bearing. Ensure the

bolt holes are free of dirt, oil, or foreign material.

Installation

NOTE: If the current bearing is reinstalled, align the

marked teeth on the swing drive pinion shaft with

the marked teeth on the bearing.

1. Using an appropriate lifting device, set the turret on the

swing bearing. If the same bearing is being used,

position it as marked prior to removal.

2. Install 36 new bolts and washers securing the bearing to

the turret. Refer to Inner Race Torquing on 9.

3. Using an appropriate lifting device, align the turret over

the carrier same position that it was before removal.

4. Carefully lower the turret into position on the bearing

plate. Be careful not to damage the swivel assembly.

5. Install all bolts and washers that are not covered by the

swing motor. Refer to Outer Race Torquing on 11.

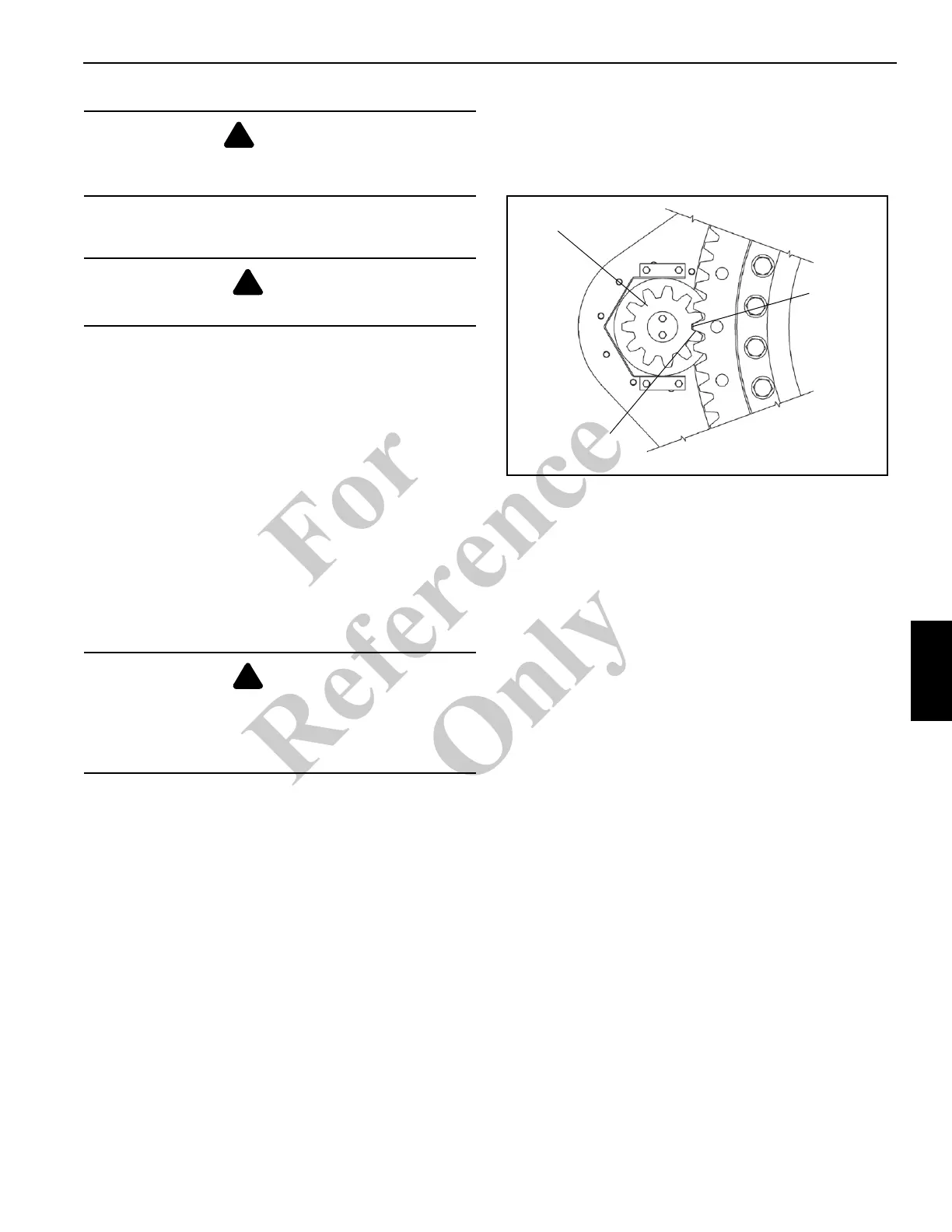

NOTE: If a new bearing is installed, a new pinion gear

must also be used. Align the high point (maximum

eccentricity) on the bearing with the high point on

the new pinion gear (Figure 6-10).

6. Install the swing drive pinion so that the high point

(maximum eccentricity) is aligned with the turret bearing

high point. Check the backlash with a 0.203 mm (0.008

in) thick shim (Figure 6-10). If the pinion must be moved

to achieve proper backlash, contact your local

distributor.

7. Plug the swivel wiring harness connectors into the

carrier receptacles.

8. Reconnect the hydraulic lines as per removal tags.

9. Install the boom and lift cylinder following the procedures

outlined in Section 4- BOOM.

10. Reconnect the batteries.

11. Carefully swing the turret so that the bolt holes that were

covered by the swing motor are accessible.

12. Install the remaining swing bearing bolts.

13. Check the slew potentiometer in the electrical swivel for

proper orientation as described below.

DANGER

Ensure the lifting device is capable of supporting the

boom assembly.

DANGER

Ensure blocking material can support the turret.

DANGER

Do not reuse the swing bearing bolts. The swing bearing

is torqued to the applied torque of the grade 8 bolts. New

bolts ensure proper torque and bolt strength for securing

the swing bearing and turret to the carrier.

0.008 Shim

Maximum

Eccentricity

Tooth

Pinion

FIGURE 6-10

Fo

r

Reference

Only

Loading...

Loading...