National Crane 1-21-2019 Control # 104-07 8-7

1400A SERVICE MANUAL LUBRICATION

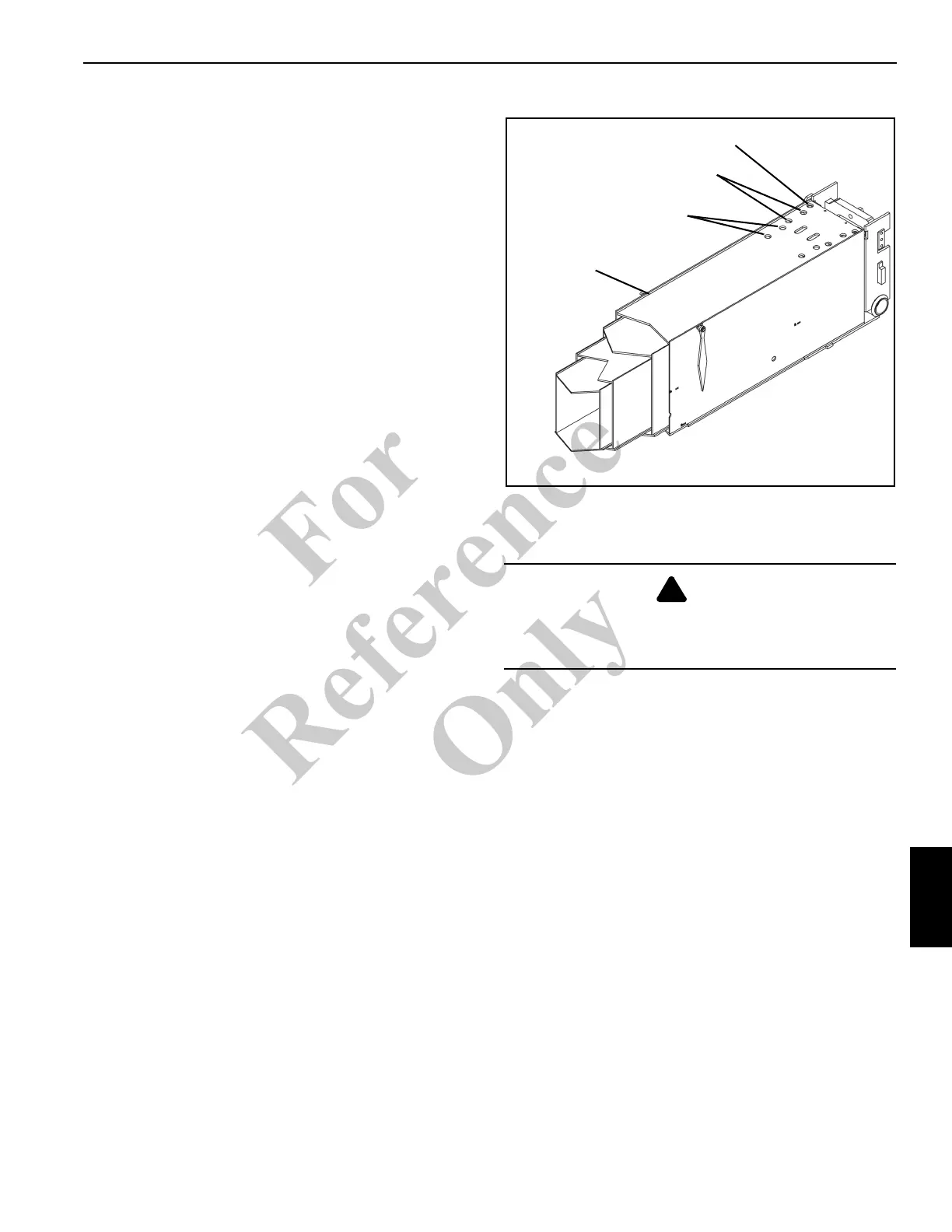

1. Fully extend and set the outriggers.

2. Apply grease at all contact points for the wear pads on

the top of the 2

nd

section through the access holes in the

1

st

section with a grease gun (Figure 8-3).

3. Extend the boom to line up the access holes on the 2

nd

section with the wear pads on the 3

rd

section. Apply

grease to all contact points for the 3

rd

section wear pads

with a grease gun.

4. Extend the boom to line up the access holes on the 3

rd

section with the wear pads on the 4

th

section. Apply

grease to all contact points for the 4

th

section wear pads

with a grease gun.

5. Raise the boom to at least 75°.

6. Extend the boom about 1/3 and retract to spread the

grease.

7. Repeat steps 2 - 5. Extend the boom about 2/3 and

retract to spread the grease.

8. Repeat steps 2 - 5. Fully extend and retract the boom to

spread the grease.

Boom Lubrication Side/Bottom Wear Pads

Recommended lubricant is EP-3MG grease.

1. Fully extend and set the outriggers.

NOTE: A fully extended boom at horizontal needs to have

an assist from a crane or forklift to retract. Lift the

front of the boom enough to relieve pressure on the

bottom wear pads. This should be sufficient for the

boom to retract.

2. Lower the boom to horizontal.

3. Fully extend the boom and apply grease to all contact

points at the side and bottom of the 2

nd

,

3

rd

, and 4

th

sections with a brush.

4. Extend and retract the boom several times until the

grease is evenly spread.

5. Repeat steps 3 and 4 as necessary to ensure the boom

is fully lubricated.

Hoist Brake Oil

Check Hoist Brake Oil

To check the hoist brake oil, remove the inspection plug

(Figure 8-4) and visually inspect the oil level. The fluid

should be visible within the bottom of the inspection hole. If

more fluid is needed, add through the brake oil vent and fill

plug hole until oil is at the bottom level of the inspection hole.

Drain /Add New Hoist Brake Oil

To drain and add new oil, remove the drain plug (Figure 8-4),

inspection plug and vent plug and drain the brake oil.

Reinstall drain plug and add fluid at the brake oil vent hole

until oil is at the bottom level of the inspection hole. Install the

inspection plug and the oil vent and fill plug. See

“Lubrication” on page 8-3.The hoist brake fill capacity

is 0.23 liter (.25 quart).

NOTE: Brake lubricants are satisfactory for operation in

temperatures from -23° C to 66° C

(-10° F to +150° F). For operation outside this

range, contact Manitowoc Crane Care for

recommendations.

DANGER

Do not, under any circumstances, work at an elevated

height without using proper fall protection as required by

local, state or federal regulations.

FIGURE 8-3

Access Holes 2

ND

Section Wear Pad

Access Holes 3

RD

Section

Wear Pad

Access Holes 4

TH

Section

Wear Pad

1

ST

Boom

Section

Fo

r

Reference

Only

Loading...

Loading...