LUBRICATION SERVICE MANUAL 1400A

8-8 1-21-2019 Control # 104-07

.

Hoist Gearbox Oil Level Check

To check the hoist gearbox oil level:

1. Rotate the drum until the oil fill/drain plug is level with the

oil level/fill inspection hole (Figure 8-5).

2. Remove the oil fill/drain plug and visually inspect the

level. The oil should be level with the bottom of the

inspection hole. If more oil is needed, add SAE 90 EP

gear lube.

NOTE: Hoist gear and brake lubricants are satisfactory for

operation in temperatures from -23°C to 43°C (-

10°F to +110°F). For operation outside this range,

contact Manitowoc Crane Care for

recommendations.

Hoist Gearbox Oil Change

Oil Drain

1. Rotate the drum until the oil/fill plug is level with the drain

hole (Figure 8-5).

2. Screw a 1” pipe drain into the drain hole so that the oil

can be drained into an approved container.

3. Remove the drain/fill plug with a 3/8” hex wrench.

4. Remove the breather.

Oil Fill

1. Remove the 1” fill pipe from the drain hole.

2. Rotate the drum until the drain/fill hole is level with the fill

hole.

3. Install a 1” fill pipe with elbow in the drain/fill hole.

4. Fill the gearbox with 1.5 quarts of new gear lube. The

lube should be level with the bottom of the fill hole.

5. Remove the fill pipe.

6. Check that the breather is not frozen. Replace if

necessary.

7. Install the drain/fill plug and breather.

.

Swing Gearbox and Brake Oil

Check and Fill Gearbox:

Visually inspect the gearbox for leaks as part of a daily crane

inspection. Fill the oil as necessary.

Change Swing Gearbox oil level:

The oil in the gearbox and brake sections is recommended

to be changed after first 50 hours of operation and every

1000 hours or 6 months of usage.

DANGER

Do not use EP type gear lubes in the brake section. This

may prevent proper operation and cause the load to fall

resulting in serious injury or death.

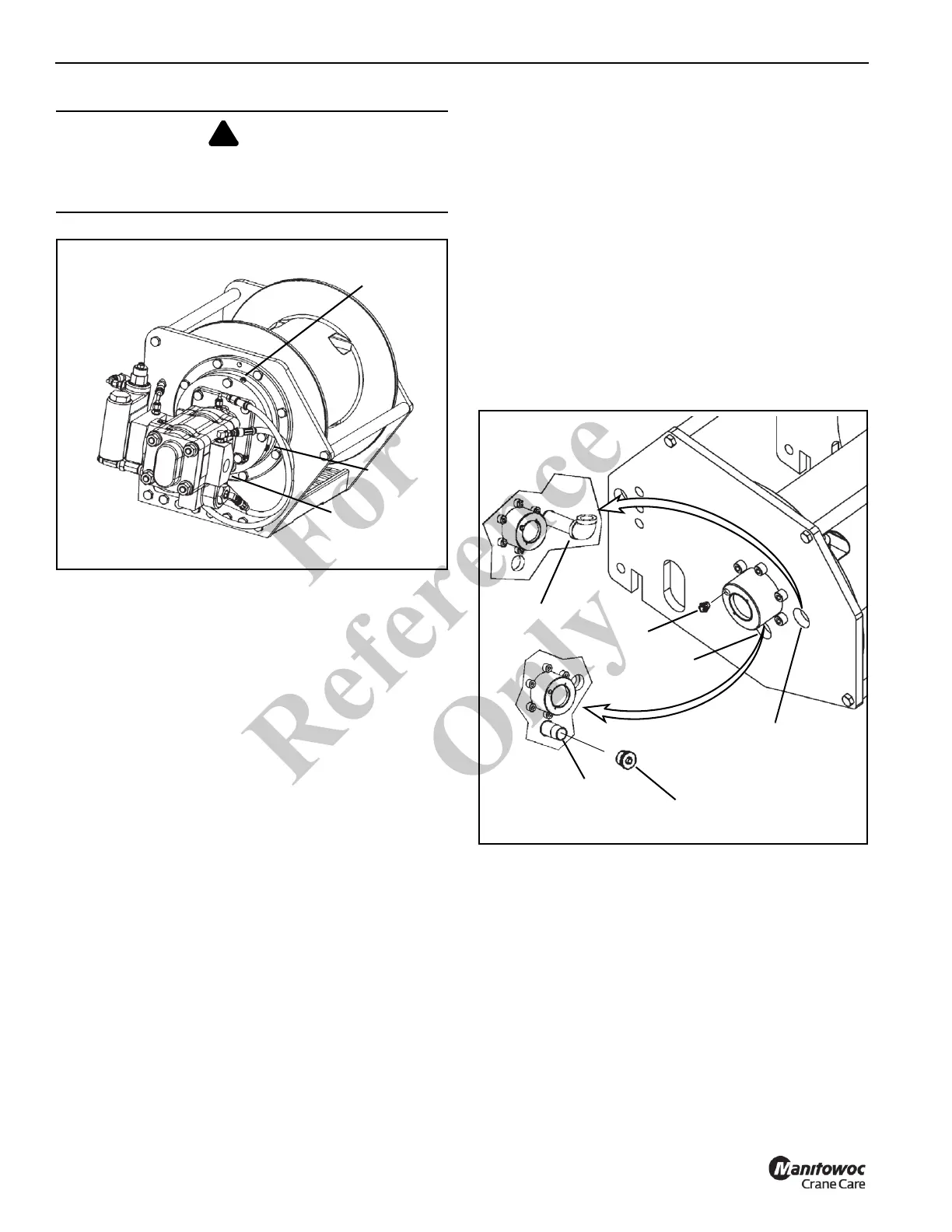

FIGURE 8-4

7142

Brake Oil Vent

and Fill Plug

Oil Brake

Drain Plug

Inspection

Plug

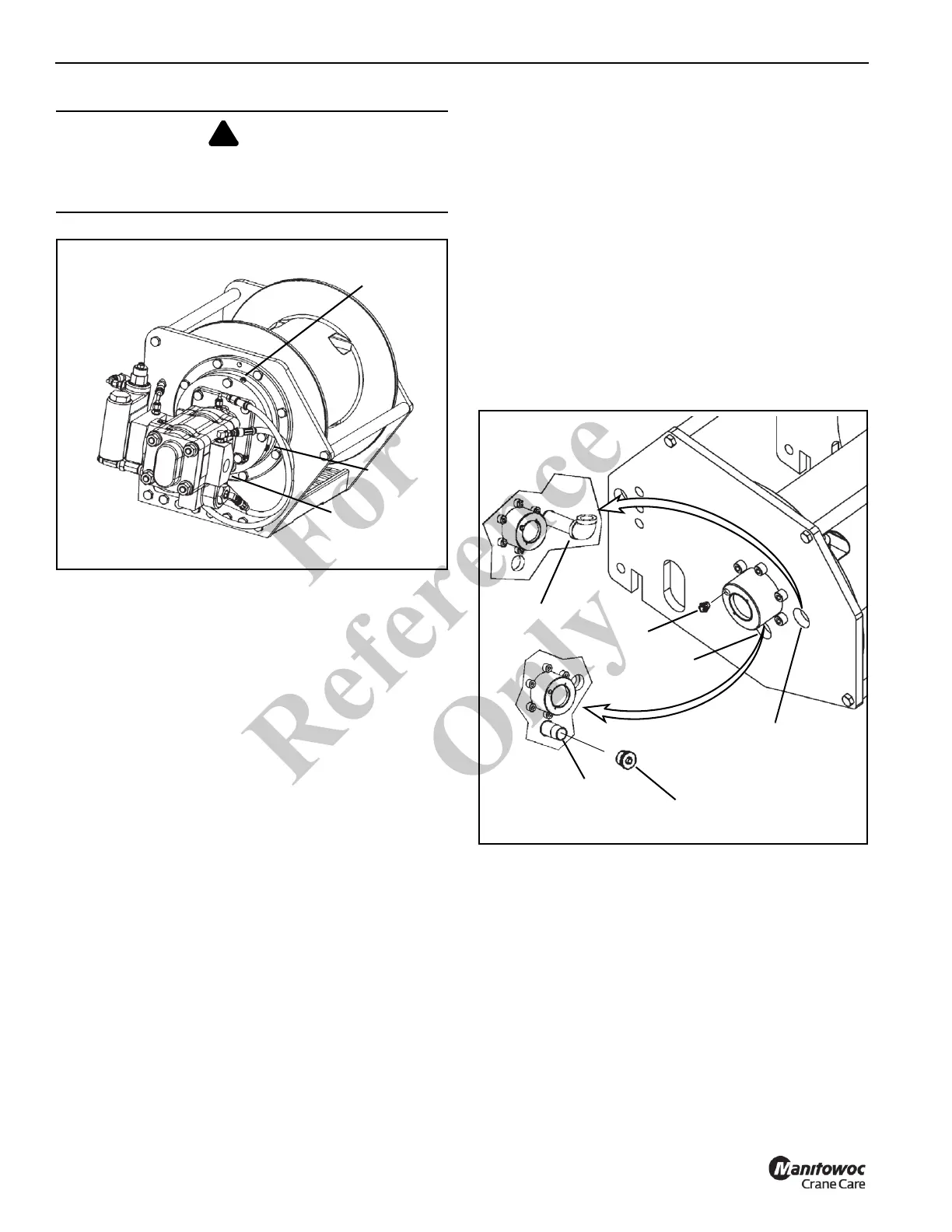

FIGURE 8-5

Gearbox

Drain Hole

Breather

Gearbox

Level/Fill Hole

Fill/Drain

Plug

1” Pipe

Drain

1” Fill Pipe

Fo

r

Reference

Only

Loading...

Loading...