HOIST SERVICE MANUAL 1400A

5-10 1-21-2019 Control # 104-07

13. Install the stator plates (19) and friction discs (18) into

the brake housing starting with a stator and alternating

friction discs and stator plates. There is one more stator

plate than friction disc so you will finish with a stator

plate.

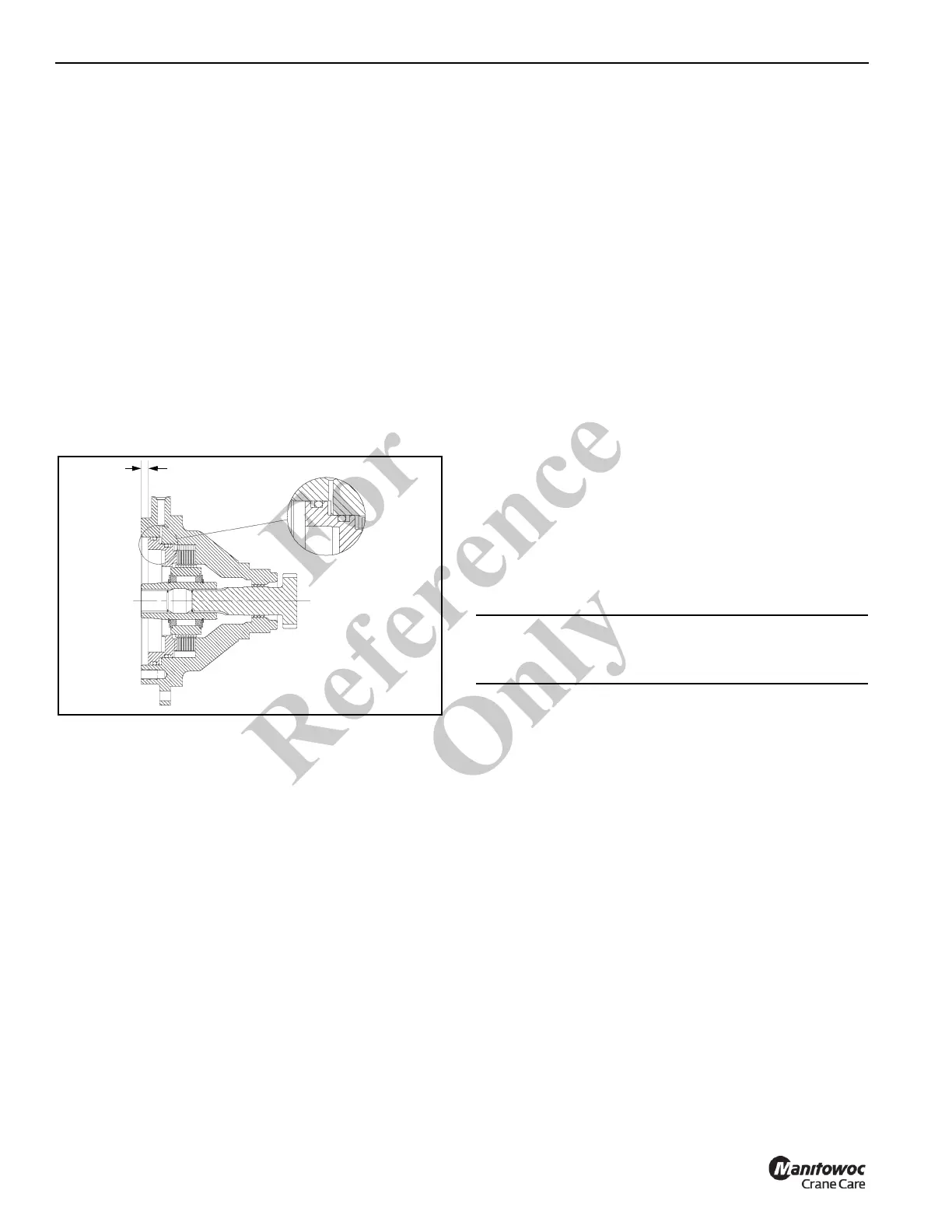

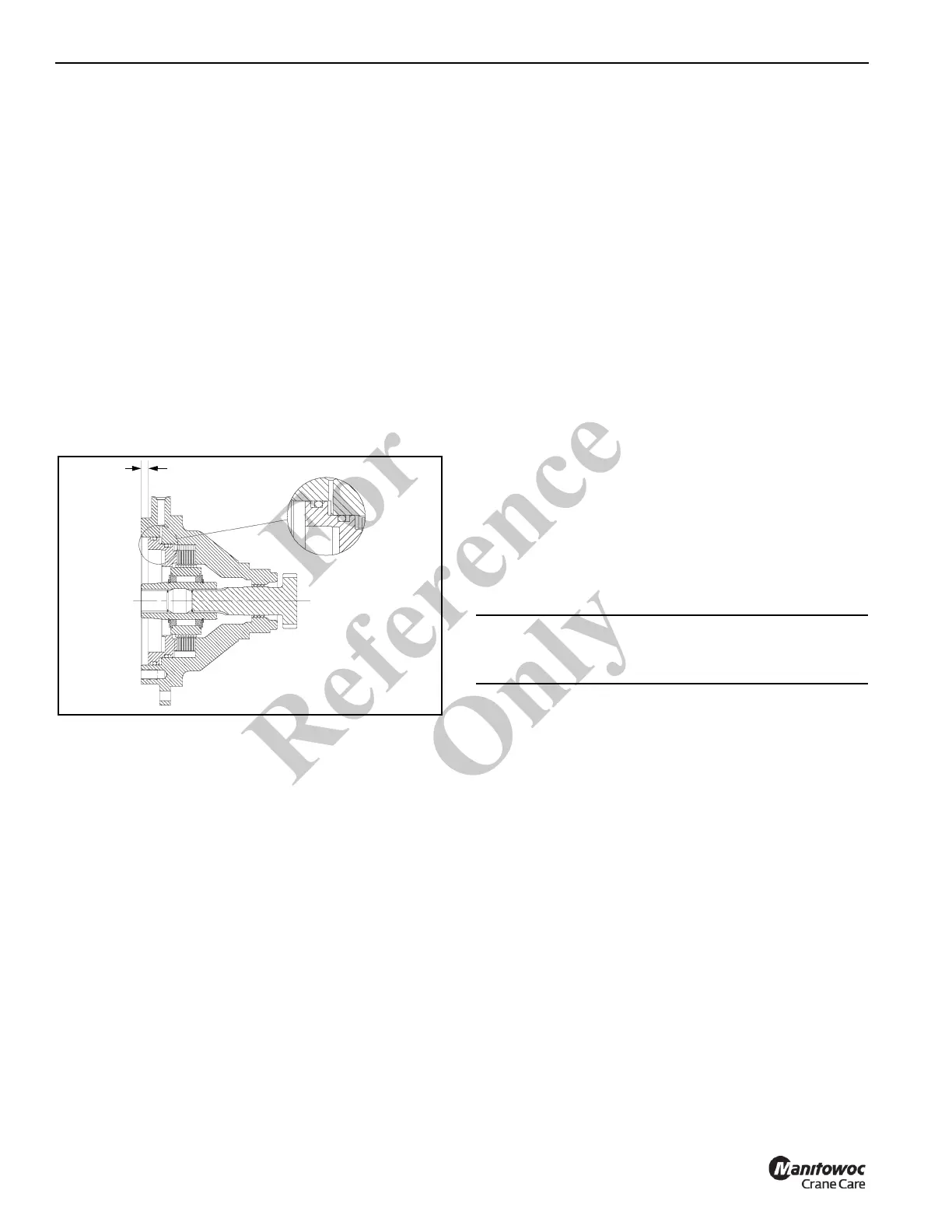

14. After installation, check the brake stackup to make sure

that the dimensions are within the tolerance shown in

Figure 5-8. If your measurement is greater than shown,

either some friction discs and stator plates have been

left out, or the friction discs are worn beyond acceptable

tolerances. If your measurement is less than shown, too

many plates or discs have been inserted or they are not

seated properly.

15. Coat the new backup rings (Items 7-7 & 7-8) and o-rings

(Items 7-1 & 7-6) with light oil and install onto the piston

(10) with the backup rings toward the outside of the

piston. See Figure 5-8 for proper o-ring and backup ring

installation.

16. Carefully install the piston into the brake housing and

gently tap it down until it is seated.

17. Install the springs (24) into the spring pockets of the

piston. If working in a horizontal position, coat the

bottom of each spring with chassis lube to keep it in

position.

18. Coat the new o-ring (7-3) with light oil and install into the

groove on the brake cover (20).

19. Install the cover (20) onto the brake housing (21) and

draw it down evenly, alternating between opposite

capscrews. Make sure that the cover is aligned

properly with the brake housing to orient the motor and

vent as they should be.

20. Check the brake release with a portable hydraulic pump.

Full release should be obtained at 250 psi, plus or minus

20 psi. Also, check the brake for proper operation by

applying 155 psi to the brake port and adapting a torque

wrench to the input shaft. The torque here in the payout

direction should be 95 to 115 lb-ft.

Planetary Set

NOTE: See Figure 5-7 for item number (#) identification.

1. Remove the spiral retaining rings (4-4, 36-4) from the

planet pins.

2. Remove the pins (4-3, 36-3) from the carrier by carefully

tapping them out.

3. Remove the planet gears, thrust washers and bearings

from the carriers.

4. Inspect the pins, bearings, and gear bores for evidence

of wear and replace if necessary.

5. On output planet sets, note that two bearings (4-6) with a

spacer (4-7) between them are used.

6. Before reassembly, be sure to insert the round plates

into the carriers (4-5, 36-5).

7. To re-assemble, be careful to line up the planet pins with

the thrust washers and bearings and then press the

knurled part of the pin into the carrier.

Motor

1. Remove the hose from the counterbalance block (12-2).

2. To remove the counterbalance block (12-2), loosen and

remove the 3 capscrews (12-3).

3. Remove the counterbalance valve (12-1) from the

counterbalance block (12-2) and inspect the small

metering hole located on the side of the cartridge valve

to make sure it is not obstructed (Figure 5-9). Also

inspect the O-rings to insure that they are not cut or

flattened.

4. Motors and cartridge valves are not serviceable in the

field. Return them to an authorized distributor for

service.

0.400 in ±0.050

(10.16 mm ±1.27)

FIGURE 5-8

CAUTION

If the pins are not lined up properly, the thrust washers

can be shattered during the pressing operation.

Fo

r

Reference

Only

Loading...

Loading...