SWING SERVICE MANUAL 1400A

6-12 1-21-2019 Control # 104-07

BEARING REPLACEMENT

Removal

1. Fully extend and set the outriggers enough to take up

the slack in the pads.

NOTE: Do not raise the machine on the outriggers.

2. Rotate the boom to about 20° off the front position so

that the boom is clear of the truck cab.

NOTE: The lift cylinder pins need to be accessible from the

truck deck.

3. Mark the position of the swing motor. The bolts

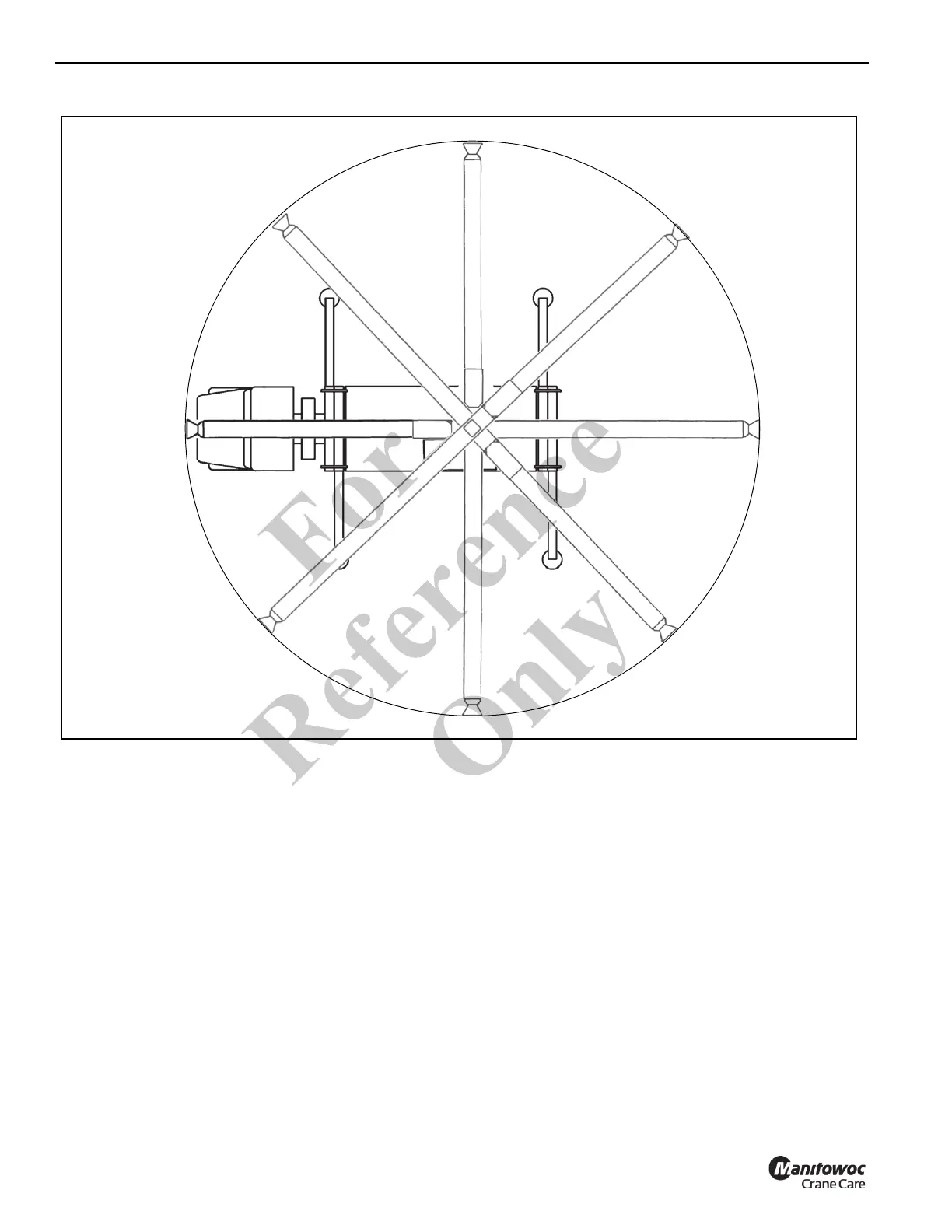

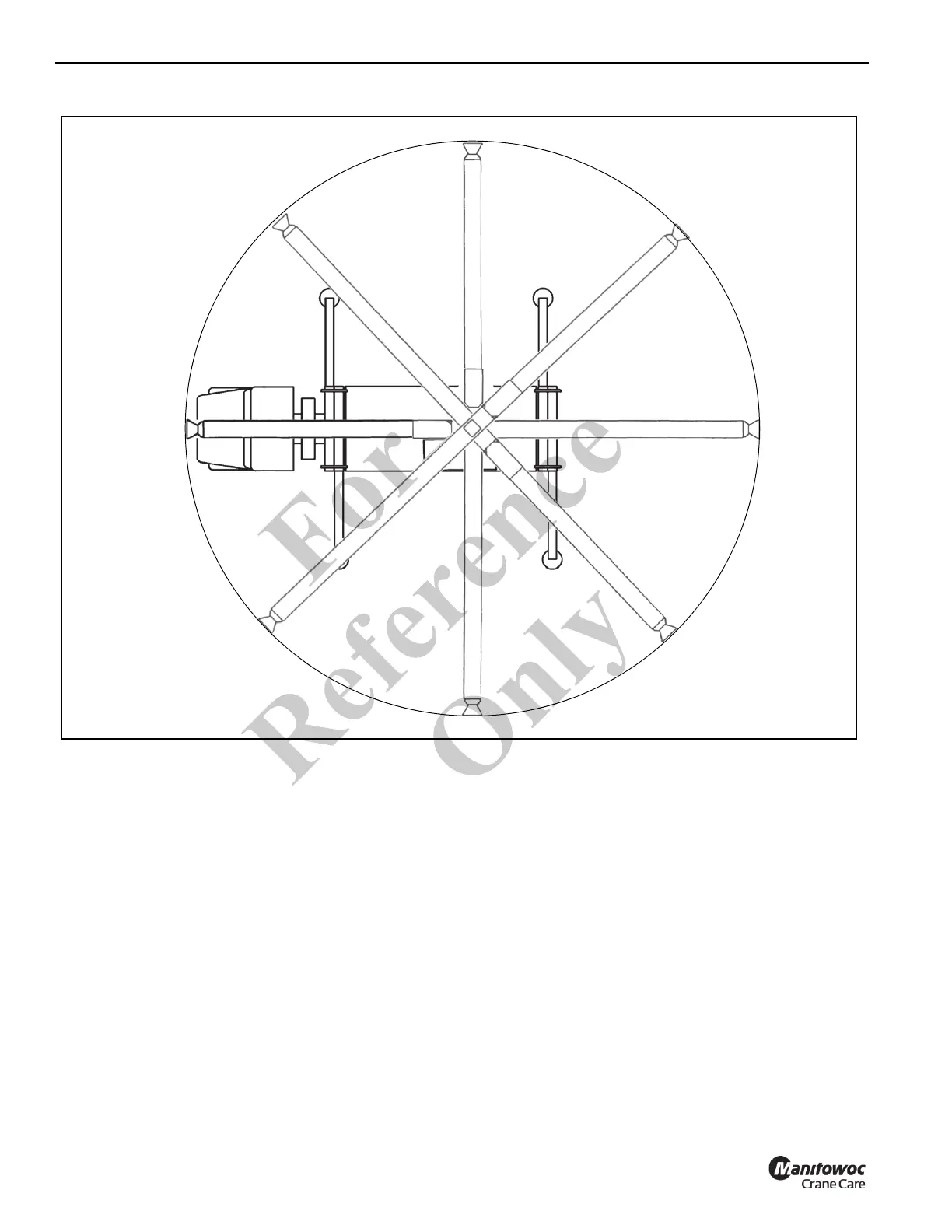

underneath the swing motor need to be removed before

any other bearing bolts are removed.

4. Rotate the boom back to the front and remove the

turntable bolts between the marks.

5. Slowly rotate the boom back to 20° off front position.

6. Elevate the boom slightly and shut down the engine.

7. Tag and disconnect the battery cables.

8. Remove the boom and lift cylinder following the

procedures outlined in “Boom Removal” on page 4-2.

9. Tag and disconnect all hydraulic lines from the swivel on

the carrier side. Cap or plug all lines and openings.

10. Disconnect the wiring harness connectors from the

carrier side of the swivel.

11. Coil the wiring harness and secure it to the swivel to

prevent damage to the harness during turret removal.

NOTE: The swivel is removed with the turret.

12. Attach a suitable lifting device to the turret. Remove any

slack in the sling. Do not pull up on the turret.

Fo

r

Reference

Only

Loading...

Loading...