National Crane 1-21-2019 Control # 104-07 3-9

1400A SERVICE MANUAL ELECTRIC SYSTEM

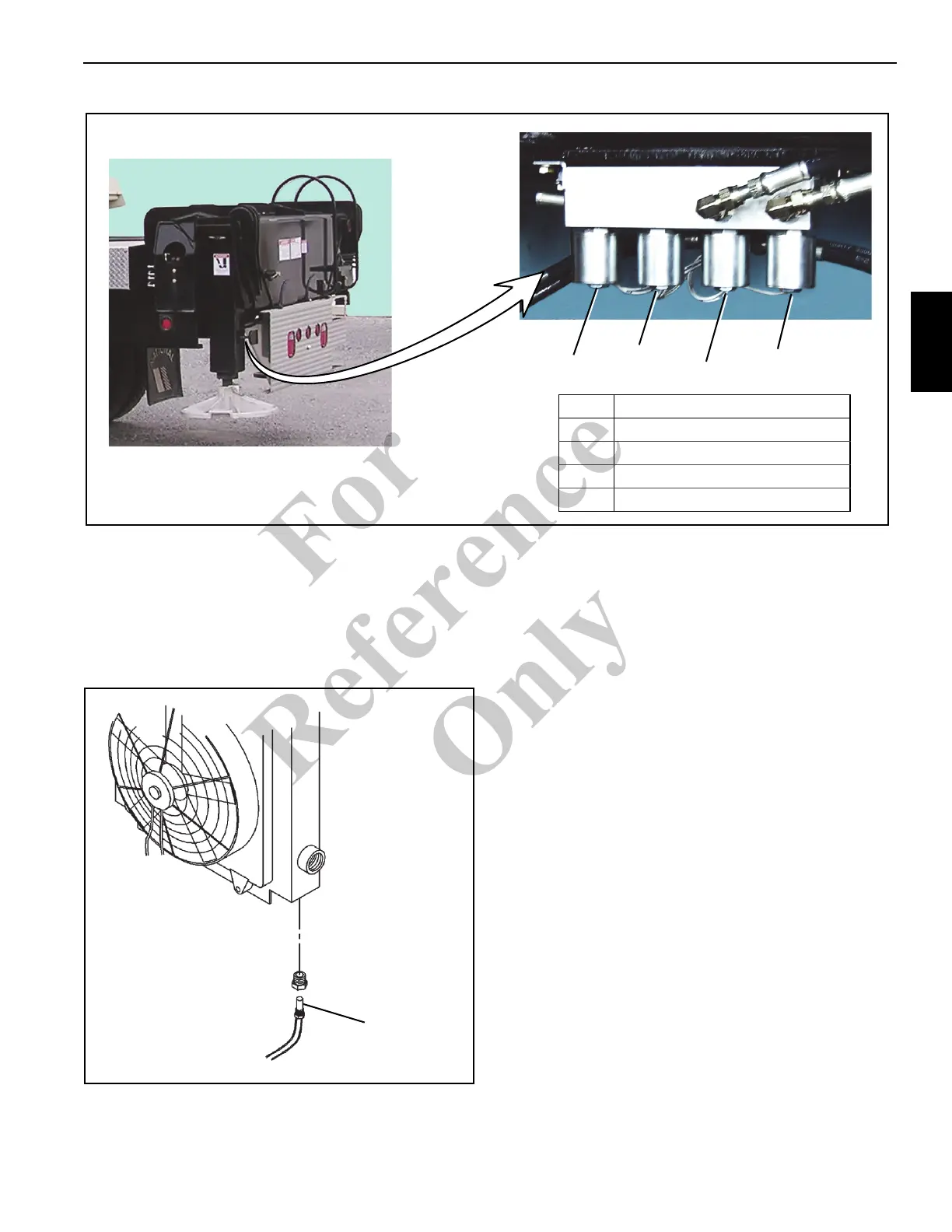

HYDRAULIC OIL COOLER

The hydraulic oil cooler (Figure 3-8) is mounted on the boom

rest. An electric fan in the cooler housing circulates air

through the cooling core when the hydraulic oil reaches 49°

C (120° F).

Not all return flow is routed through the oil cooler. A check

valve 206 kPa (30 psi) limits the flow through the cooler.

Since hydraulic oil is thicker when it is cold, less oil is routed

through the cooler when it is cold than when it is hot.

The cooler electrical system is made up of the following:

• Electric Fan

• Fan Relay

• Temperature Senor

The temperature sensor is located in the cooling core and

energizes the fan relay when the hydraulic oil reaches 49° C

(120° F). The fan relay is in the VEC module and turns the

fan on when energized. If the fan does not run when the

hydraulic oil is hot check the temperature sensor, relay, and

fan motor.

NOTE: The fan runs constantly if the sensor fails.

HYDRAULIC TEMPERATURE SENSOR

WARNING LIGHT

A warning light on the crane cab console is illuminated when

the hydraulic oil has exceeded the maximum recommended

temperature. A sensor in the hydraulic swivel port #4

monitors the temperature of the return oil and turns the light

on when the hydraulic oil reaches 96° C (205° F). If the light

fails to illuminate, check the light and the temperature sensor

in swivel port #4.

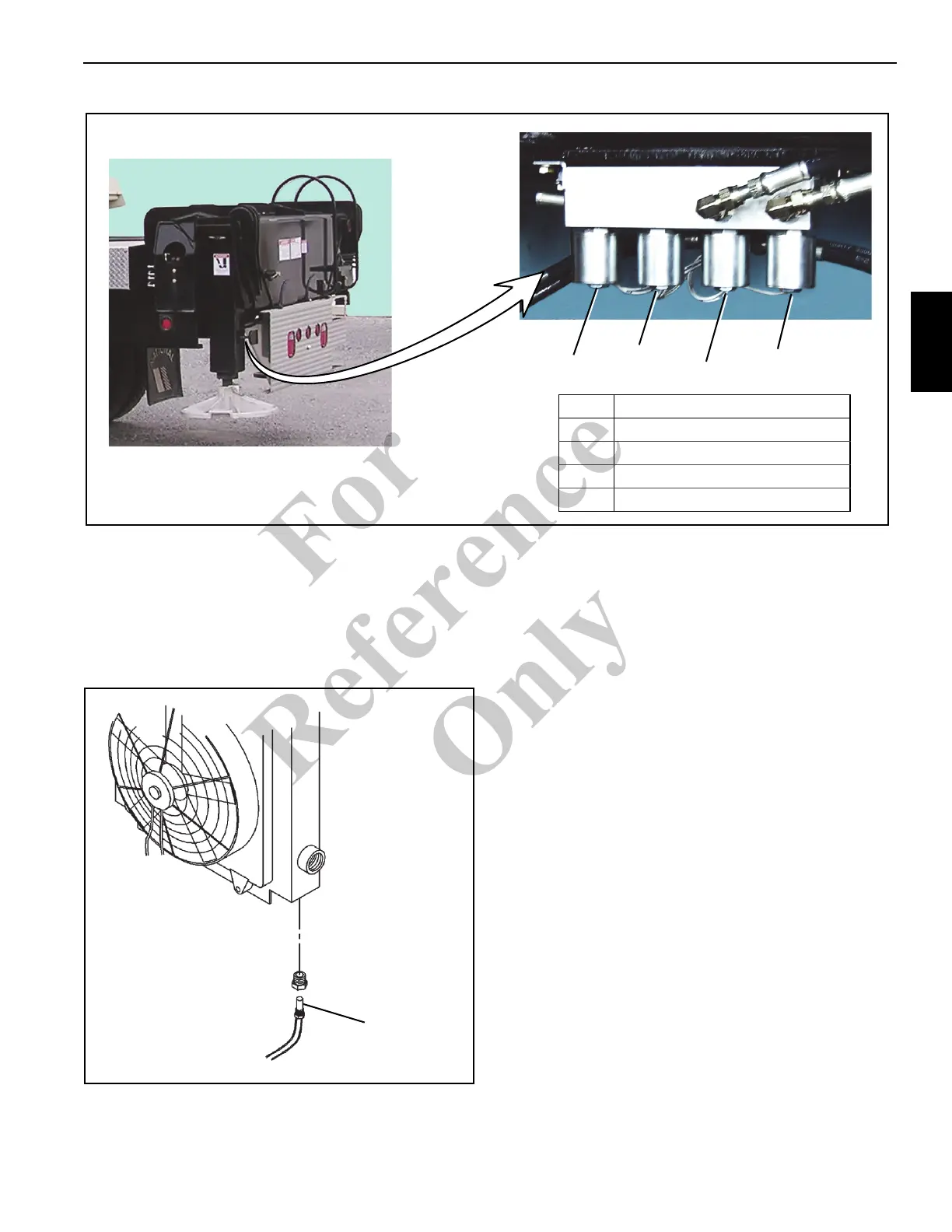

Item Solenoid

1 Passenger Side Stabilizer

2 Passenger Side Beam

3 Driver Side Beam

4 Driver Side Stabilizer

1

2

3

4

FIGURE 3-7

NOTE: Solenoid as

viewed from the

rear of the truck.

FIGURE 3-8

Fan

Temperature

Sensor

Fo

r

Reference

Only

Loading...

Loading...