National Crane 1-21-2019 Control # 104-07 9-19

1400A SERVICE MANUAL CRANE INSTALLATION

Hydraulic System Connection

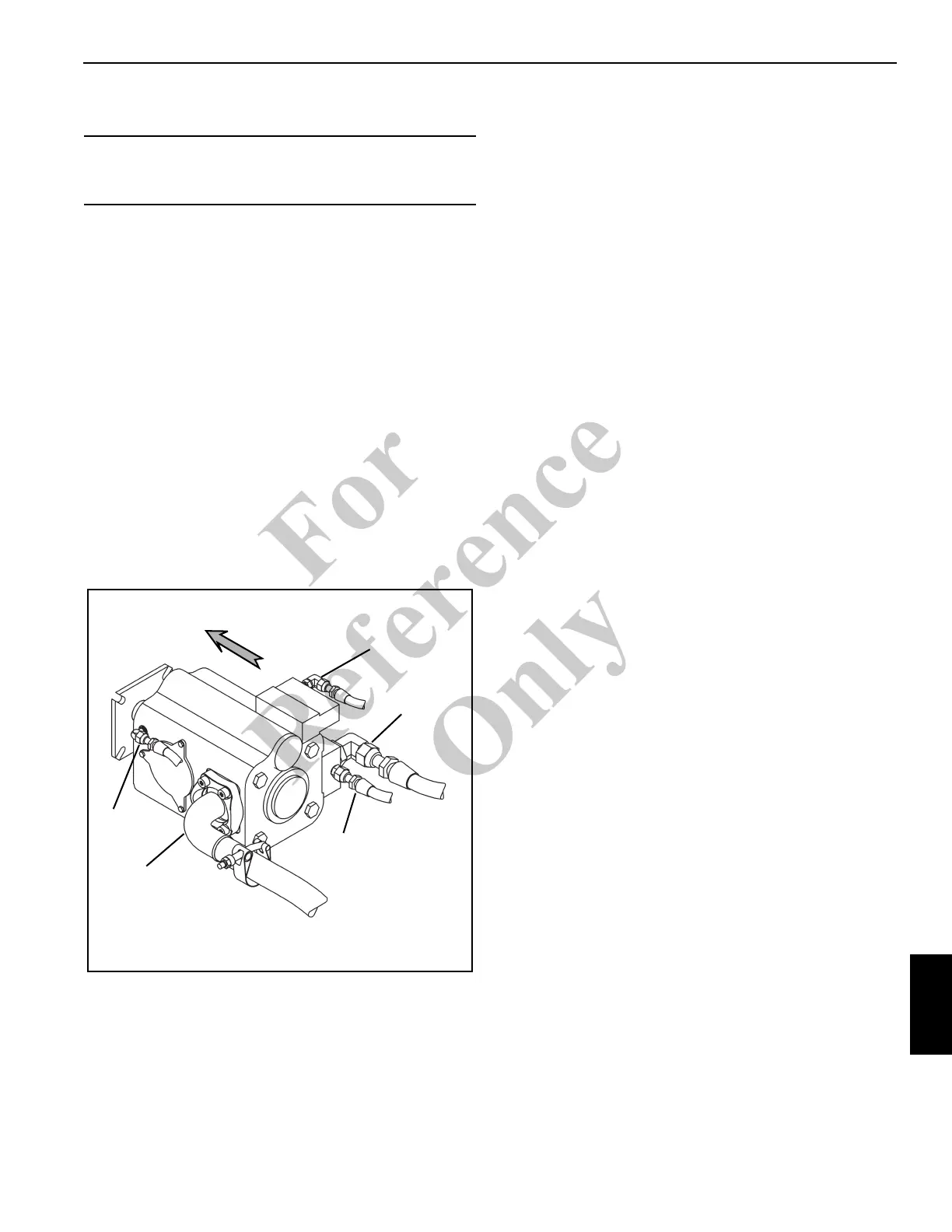

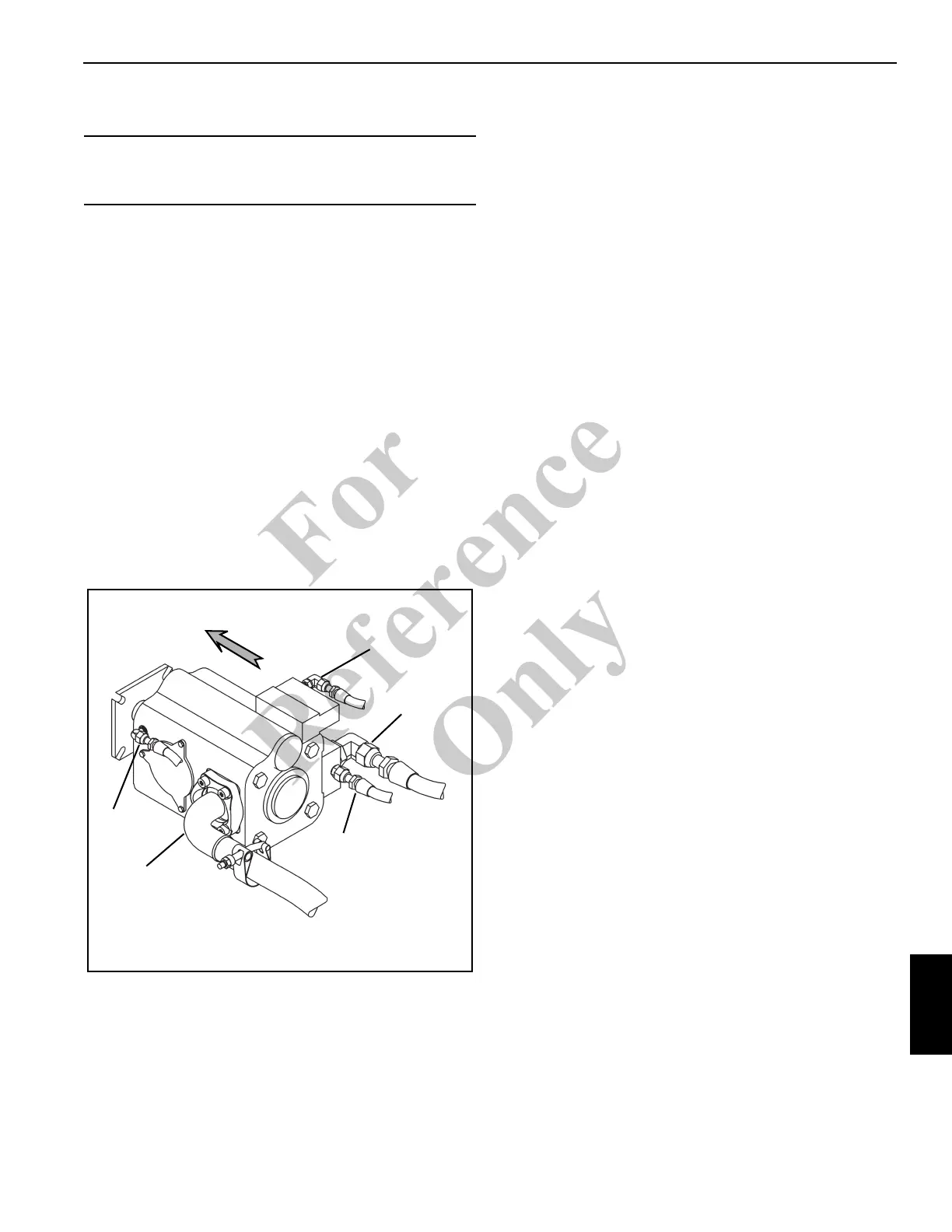

The hydraulic system pressure is supplied by a hydraulic

piston pump mounted on the truck power take off (PTO). The

pump is driven counter clockwise and supplies the following

at governed rpm:

• 132 LPM (35 GPM) to the hoist

• 132 LPM (35 GPM) to the boom and telescope

• 61 LPM (16 GPM) to the turn and outrigger circuit.

Connect the hydraulic hoses to the pump sections as

marked.

12. Adjust the throttle for the engine RPM and PTO ratio to

get proper pump shaft speed.

13. Measure the overall height of the crane and truck. Post

the overall height measurement inside the truck cab to

inform the driver of the overall height.

14. The Initial Crane Run in Procedure must be completed

before the stability test is started.

RCL CALIBRATION

After the crane has been installed and all electrical and

hydraulic connections are completed, calibrate the RCL.

Calibrate the RCL as described in the RCL manual titled

Calibration/Service Manual.

INITIAL CRANE RUN IN PROCEDURE

1. Put the unit in an open area where the crane can be run

through all functions.

2. Engage the PTO and do the following:

• Start the truck engine from the crane cab.

• Program the RCL.

• Run the truck engine at idle.

• Turn the crane power switch on and operate the

crane and outriggers though all of their functions at

least six (6) times to purge the cylinders of air.

• Operate the control valves slowly with the truck

engine at idle and cycle each cylinder through its

complete stroke each time.

• Check to see that the movement of the outriggers

and boom correspond with the direction indicated

on switches and levers.

• Refer to the hydraulic and electrical sections and

hydraulic or electrical schematics in this manual.

NOTE: Add oil to reservoir as required to keep air from

reentering the system.

3. Set the throttle according to engine RPM and PTO ratio

to get the proper pump shaft speed.

4. After all the cylinders have been run through six

complete cycles, stow the crane with the outriggers

retracted. The oil level should be visible at the full mark

of the sight gage.

5. The lift and stability test must now be performed.

6. After testing is completed, check the torque on all

bearing, mounting and all cable clamp bolts.

STABILITY TEST

The purpose of the stability test is to verify that the rated load

can be lifted with an 85% tipping factor. With an 85% tipping

factor, the crane can lift a rated load and be at 85% of the

tipping condition or less.

CAUTION

Make sure the gate valve on the return line is open before

starting the pump or damage to the pump could result.

FIGURE 9-15

FRONT

To Outriggers

and Swing

Load Sense

To Hydraulic

Swivel

From Tank

Drain to

Tan k

Fo

r

Reference

Only

Loading...

Loading...