HYDRAULIC SYSTEM SERVICE MANUAL 1400A

2-14 1-21-2019 Control # 104-07

Hydraulic Filter Replacement

The filter is mounted in the oil reservoir, and is a replaceable

element type.

The filter requires a 5 Micron replacement element. The filter

must be serviced with National Crane replacement elements

at recommended intervals to assure the warranty remains in

effect.

Element Removal

1. Shut down the hydraulic system.

2. Wipe any dirt from the filter head and cap assembly.

3. Loosen the six bolts securing the filter cap to the filter

head.

4. Twist to unlock and remove the filter cap.

5. Remove the filter element from the filter bowl (housing).

6. Ensure the new filter element is correct by comparing

their part numbers with the part numbers of the used

filter element.

7. Discard the used filter element.

Element Installation

1. Install the new element into the filter bowl (housing).

2. Install the filter cap and twist to lock in place.

3. Tighten the six bolts to secure the filter cap.

4. Activate the hydraulic system and check for leaks. Make

repairs as needed.

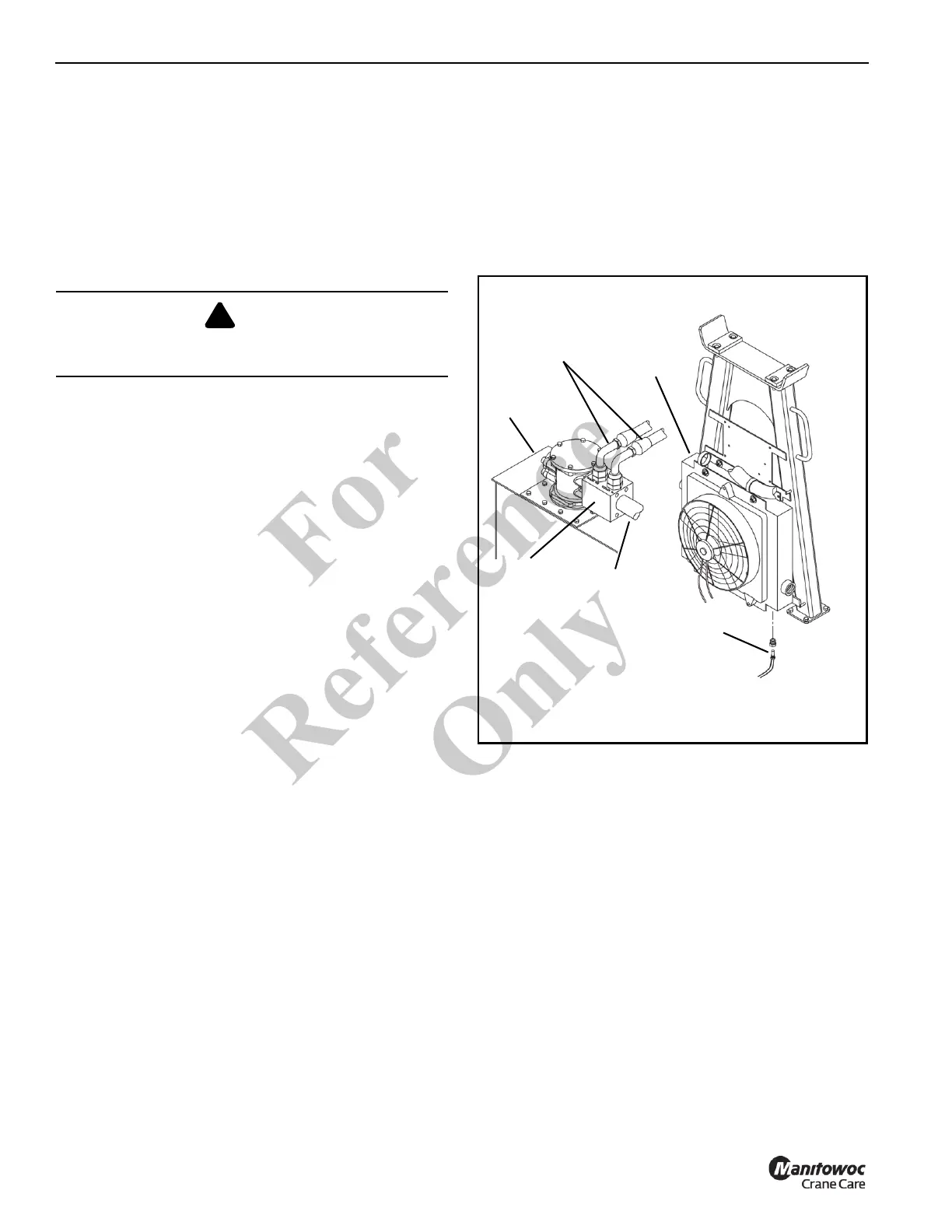

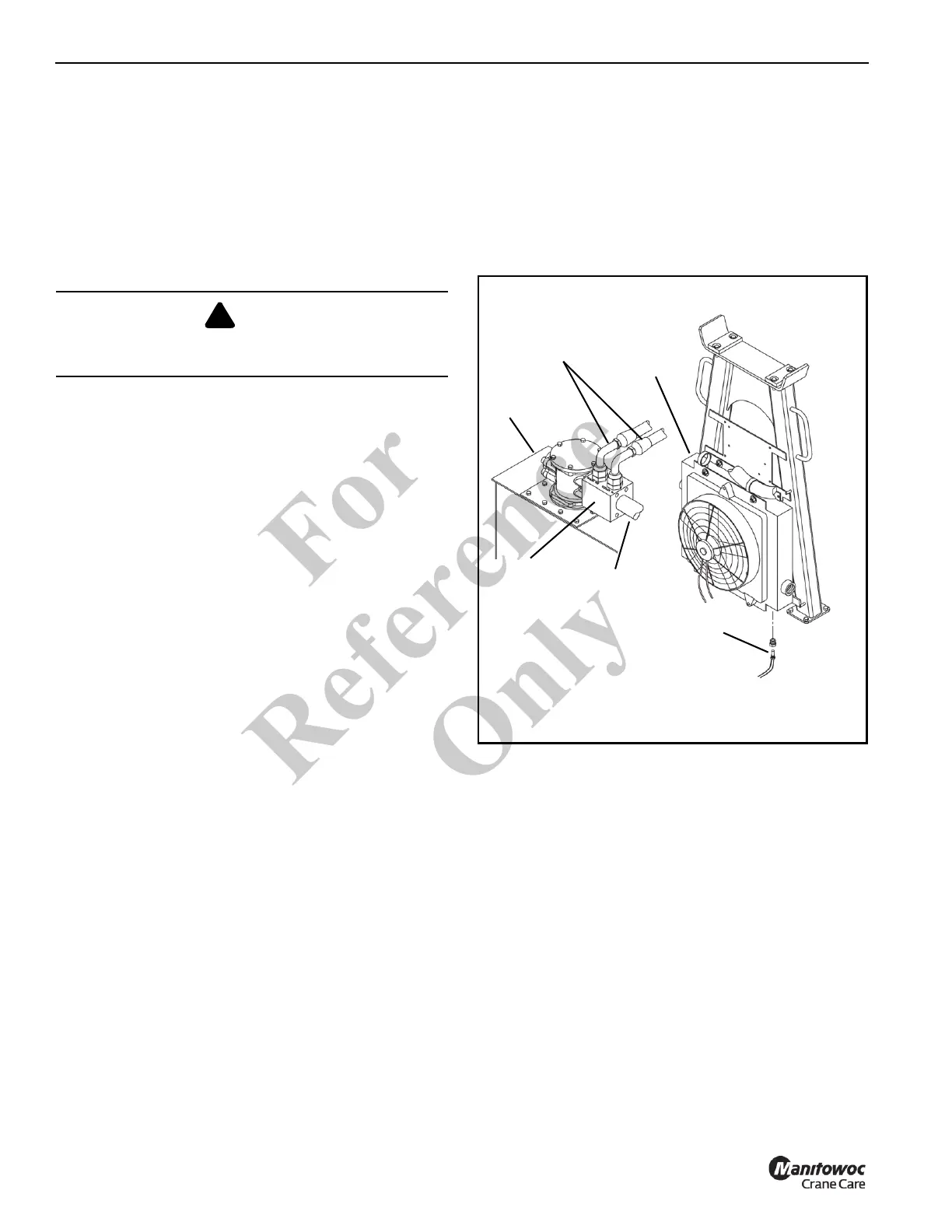

Hydraulic Oil Cooler

A hydraulic oil cooler (Figure 2-9) is located on the boom

rest. The oil cooler return circuit is in parallel with the

reservoir return circuit. A 30 psi (206 kPa) check valve in the

cooler line regulates flow through the oil cooler. When the

hydraulic oil is cold, most of the return oil goes directly to the

tank. As the oil warms up and becomes thinner, more oil

goes through the cooler.

NOTE: A temperature sensor located in swivel port (4B)

monitors the temperature of the hydraulic oil and

illuminates a light on the crane cab console when

the temperature reaches 96° C (205° F).

The oil cooler fan is controlled by a relay in VEC module. To

access the relay, remove the assess panel on the side of the

housing. A temperature switch located in the cooling core

energizes the fan relay when the oil temperature reaches 49

°C (120°F).

NOTE: If the temperature sensor in the cooling core fails,

the fan runs continuously even when the crane

ignition is off.

Oil Cooler Service & Maintenance

The heat exchanger must be kept clean to allow for efficient

operation of the cooler system. Frequent washing of the heat

exchanger core eliminates oil film, road dirt, and other

foreign object buildup on the heat exchanger fins which

reduces cooling efficiency.

Frequent inspection and tightening of hose clamp line

connections eliminates the possibility of end connection

failure due to back pressure from cold startup.

If cooler the system fails to provide adequate performance,

reduced air or oil flow through the heat exchanger is the

probable cause. Inspect the cooling fan for proper operation.

Any obstructions to air flow needs to be corrected (cooler too

close to other truck components, foreign matter in heat

exchanger fins, etc.). All hydraulic lines should be

periodically checked for obstructions, hose kinks or other

flow restrictions.

DANGER

Ensure that hydraulic system is shut down and the

pressure is relieved.

Hydraulic

Oil Cooler

FIGURE 2-9

Bypass

Valve

Fan Temperature

Switch

Return

To Oil

Cooler

Hydraulic

Tank

Fo

r

Reference

Only

Loading...

Loading...