Manitowoc Published 10-09-2020, Control # 259-06 5-35

MLC80A-1/MLC90A-1/MLC100A-1/MLC100-1 SERVICE/MAINTENANCE MANUAL HOISTS

• All ropes—One outer wire broken at the point of contact

with the core and protruding or looping out of the rope

structure. Additional inspection is required.

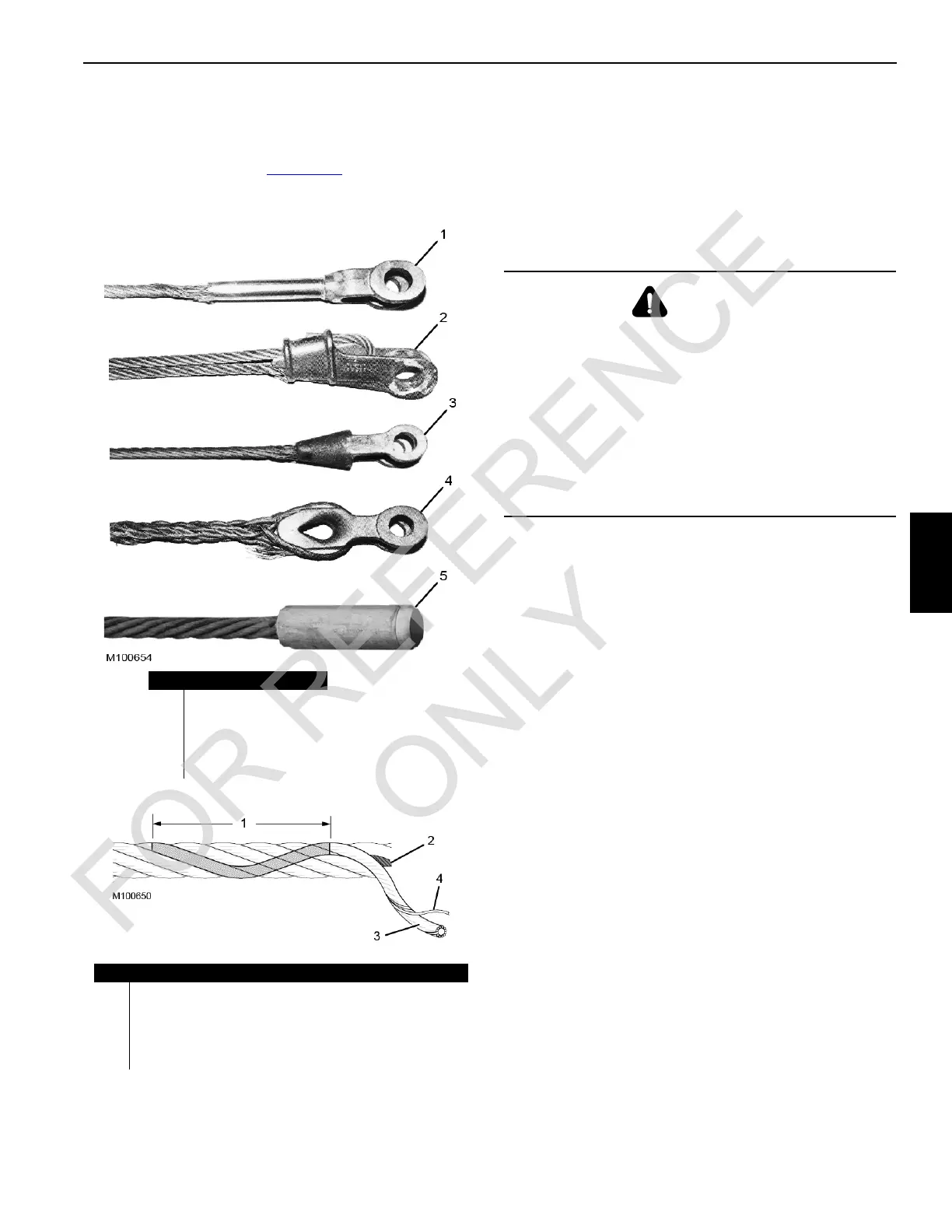

• End attachments (see Figure 5-23

)—When more than

one broken wire appears at the attachment, replace the

rope or cut off the affected area and reattach the fitting.

Rope That Has Been Idle a Month or More

Wire rope must be given a complete inspection if it has been

idle for a month or more. The inspection must be performed

by a qualified inspector looking for the damage identified

under both daily and periodic comprehensive inspection.

NOTE: Wire rope may be purchased through Manitowoc

Crane Care Lattice Team.

Distributing Wire Rope Wear

Wire rope wear at the “critical wear points” can be reduced

and the life of the wire rope extended by moving the rope at

regular intervals so that different sections of the rope are

subjected to the wear points. This practice can also help

correct spooling problems and rope vibration.

To move the wire rope, cut off a piece of the rope at the worn

end and refasten. The piece should be long enough to move

the wire rope at least one full drum wrap.

If the wire rope is too short to allow cutting off a piece,

reverse the rope end for end and refasten it.

Item Description

1 Swagged Socket

2 Wedge Socket

3 Poured Zinc Socket

4 Hand-Spliced Socket

5 Button Socket

FIGURE 5-23

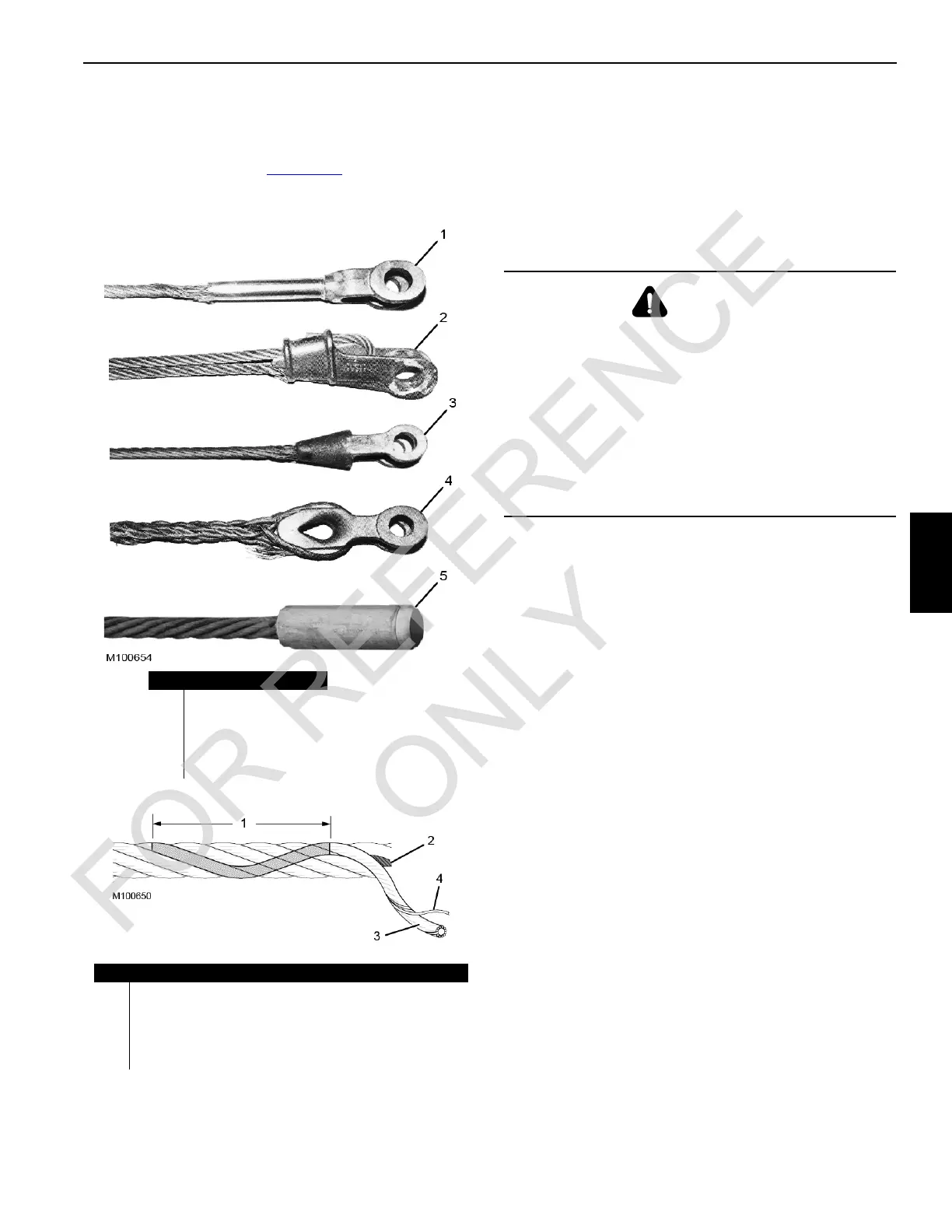

Item Description

1 Lay Length: distance in which one strand makes one

complete revolution around core

2Core

3Strand

4Wire

FIGURE 5-24

WARNING

Falling Load Hazard!

Replacement wire rope can break if it does not meet

Manitowoc Cranes specifications given in the following

publications supplied with your crane:

• Wire Rope Specifications Chart located in the

Capacity Chart Manual (for load lines)

• Boom or Jib Assembly drawings located in the

Operator Manual (for boom or luffing hoist)

• Mast Assembly drawing located in the Parts Manual

Loading...

Loading...