Manitowoc Published 10-09-2020, Control # 259-06 8-3

MLC80A-1/MLC90A-1/MLC100A-1/MLC100-1 SERVICE/MAINTENANCE MANUAL UNDERCARRIAGE

• Simultaneously, the travel brakes are released to allow

travel.

The following sensors provide feedback to the control

system:

• Pump A and Pump B pressure sensors

• Left travel pressure sensor

• Right travel pressure sensor

The control system uses this feedback to adjust the pump

and motor flows to maintain the speeds commanded by the

handles.

No Travel

When the travel control handles are in the neutral position,

the travel pumps are de-stroked and the left and right travel

proportional control valves remain in the center position,

blocking hydraulic flow from the pumps to the travel motors.

The travel brake solenoid is deenergized, allowing spring

force to apply the travel brakes.

Travel Motor Flushing

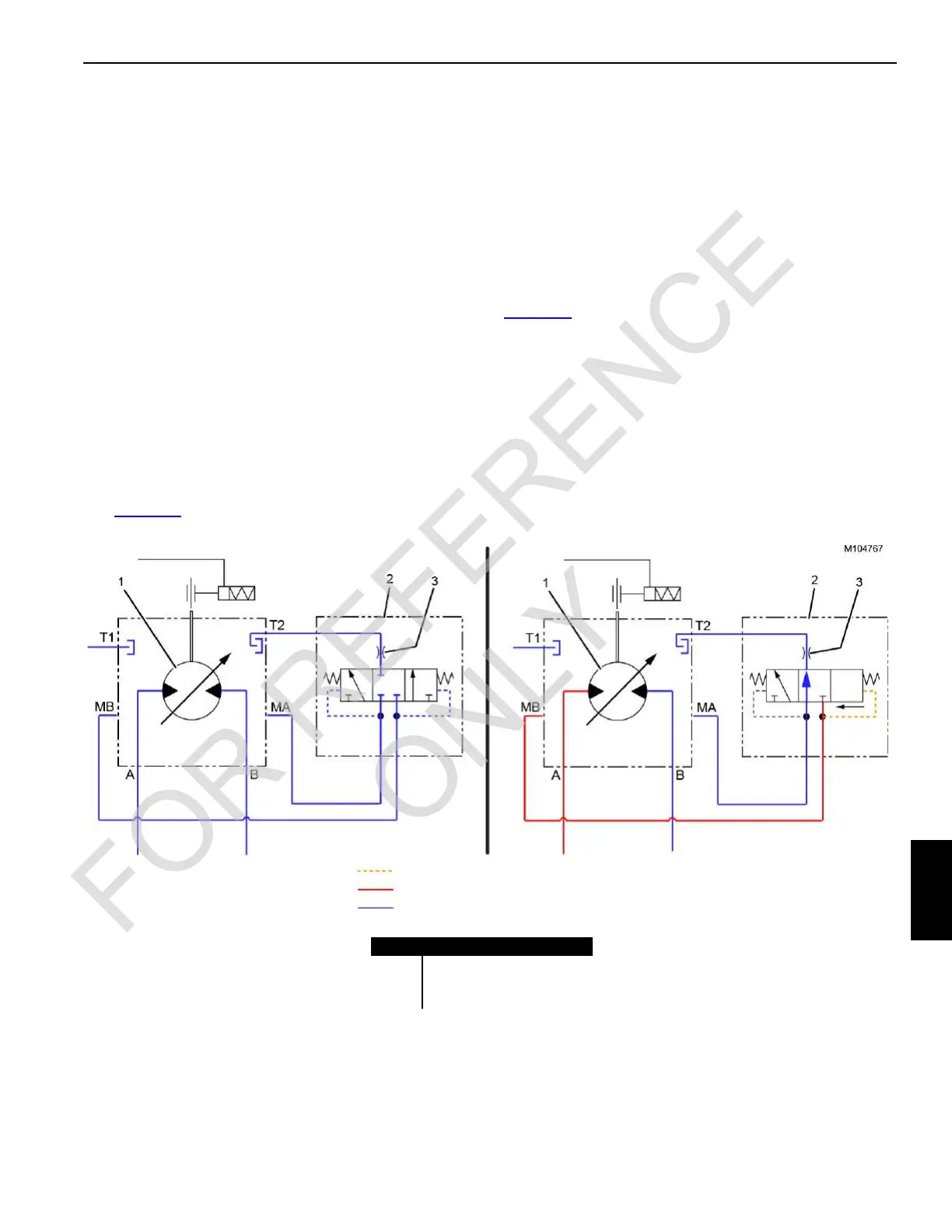

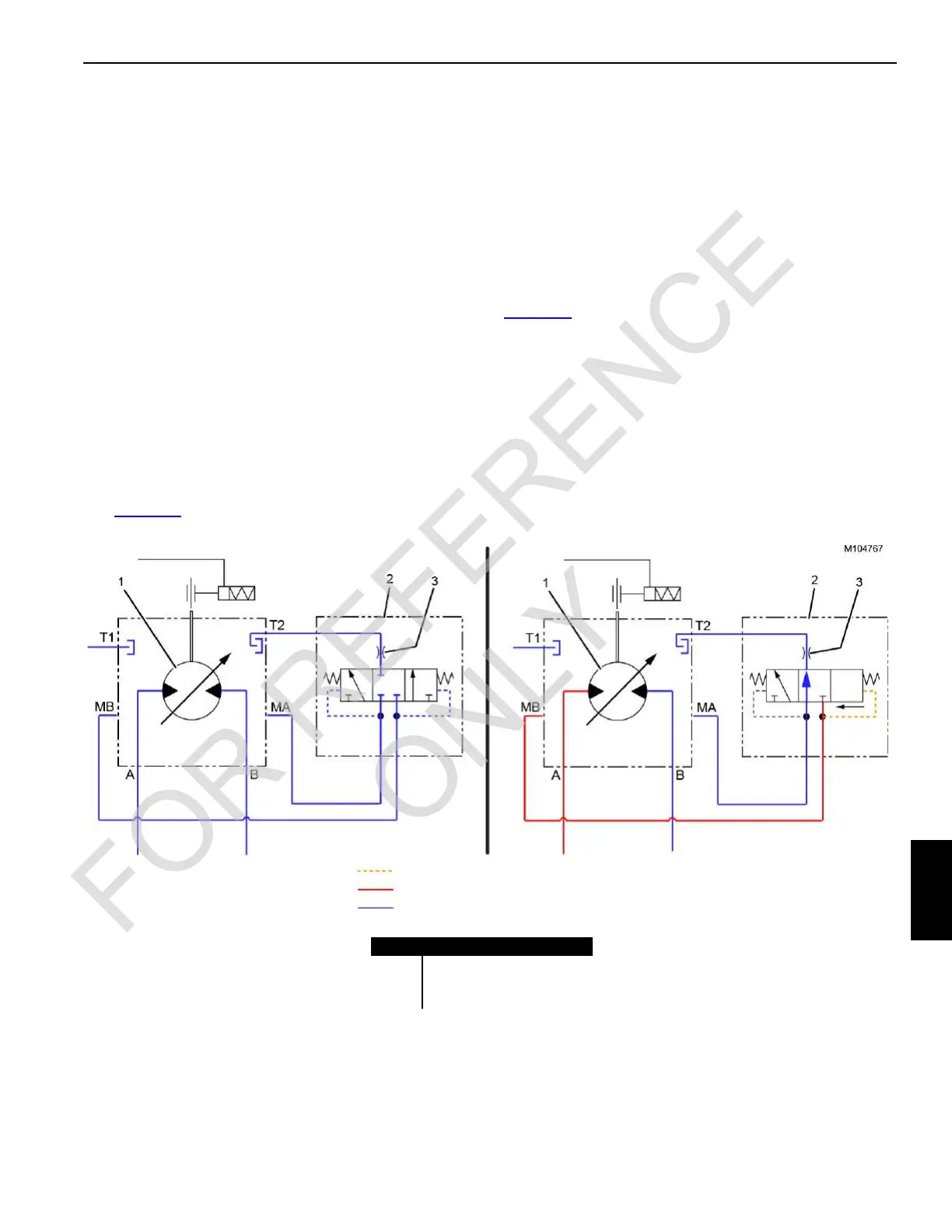

See Figure 8-1.

The purpose of the travel motor flushing circuit is to provide a

continuous flow of flushing oil to the case of both travel

motors while the crane is traveling.

Each travel motor (1) has a 3-position, pilot-operated

flushing valve (2) for controlling the flushing circuit.

When the travel system is in neutral (View A), the flushing

valve is spring centered to the closed position, and there is

no flushing oil flow through the travel motor.

When a crawler is operated (View B), oil from the pump is

delivered to the corresponding motor port via the

proportional travel control valve. For the example in

Figure 8-1

, oil is being delivered to motor port A.

In this example, system pressure from motor port MB shifts

the flushing valve open allowing return oil from motor port

MA to flow through the orifice (3). The orifice meters return

oil to the motor case port T2 and the oil returns to tank via the

motor case port T1.

When the motor is operated in the opposite direction,

pressure from motor port MA shifts the flushing valve (2) in

the opposite direction shown, and oil from motor port MB

flows through the orifice (3) and back to tank via the motor

case ports T2 and T1.

FIGURE 8-1

Pilot Pressure

System Pressure

Exhaust (tank)

Item Description

1Travel Motor

2 Flushing Valve

3 Orifice: 8 L/min (2.1 gpm)

Loading...

Loading...