UNDERCARRIAGE MLC80A-1/MLC90A-1/MLC100A-1/MLC100-1 SERVICE/MAINTENANCE MANUAL

8-8

Published 10-09-2020, Control # 259-06

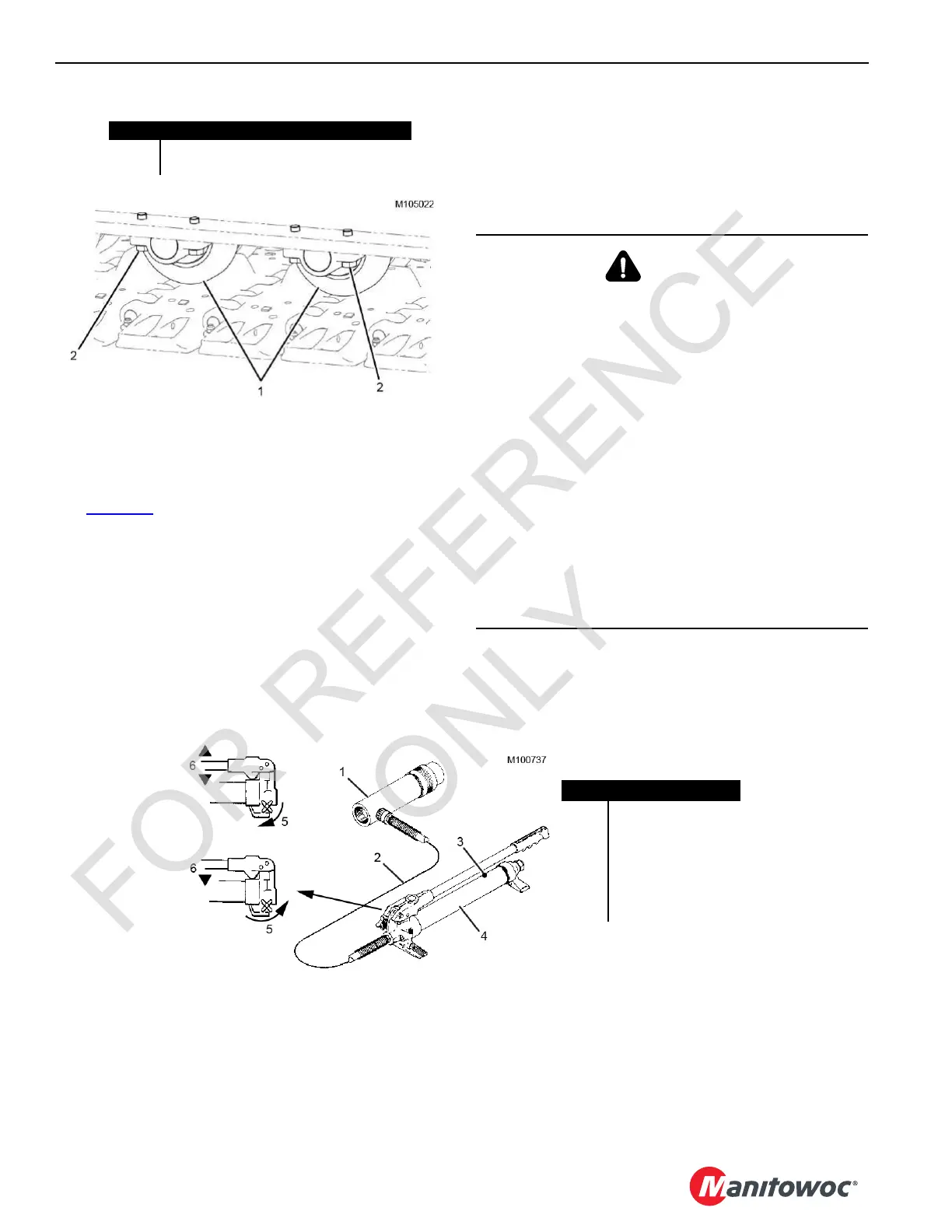

INTERMEDIATE ROLLER BOLT TORQUE

See Figure 8-5.

Annually, Every 2000 Hours of Engine Operation, or

Every 250 Hours of Travel Operation, Whichever Occurs

First

1. Check the torque of the bolts (2) at each intermediate

roller (1). The bolts must be at 610 Nm (450 ft-lb) torque.

The bolts must not turn.

2. Replace ALL loose bolts with new bolts and torque as

follows:

• Clean threads with solvent/degreaser as needed

• Apply LOCTITE™ 263 to threads

• Torque bolts to 895 Nm (660 ft-lb)

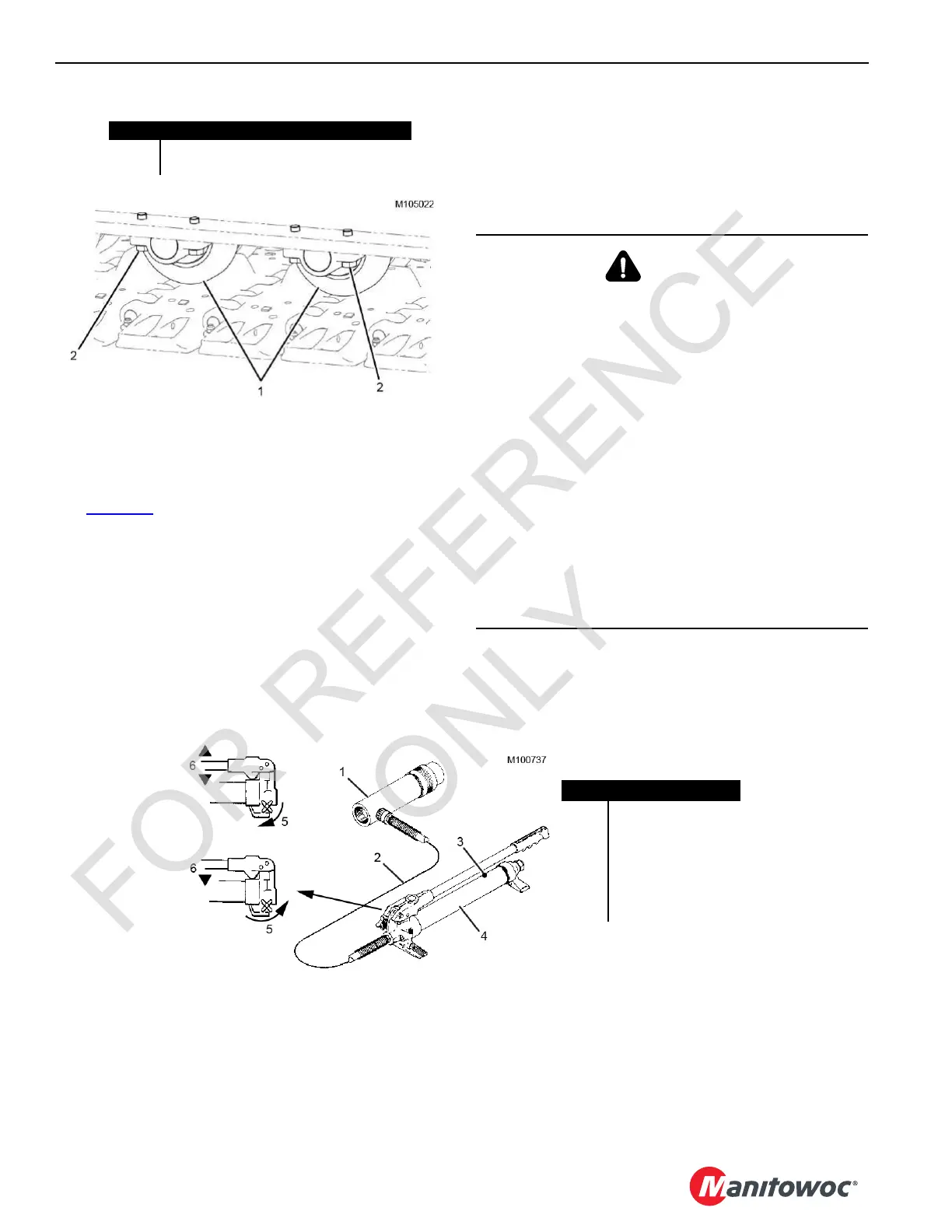

CRAWLER HAND PUMP AND CYLINDER

FIGURE 8-5

Item Description

1 Intermediate Roller (qty 11 each crawler)

2 Bolt with Flat Washer (qty 4 each roller

WARNING

Hand Pump Explosion

The hand pump and cylinder is provided for crawler

adjustment only, any other use is neither intended nor

approved.

Wear safety glasses and other personal protective gear

when operating the hand pump.

Do not set the pump relief valve higher than 10,000 psi

(700 bar). Higher pressure can cause components to

explode.

The pump is not vented. It can explode if subjected to high

pressure. Do not attempt to return more oil to the pump

than it is capable of holding. Do not overfill the pump.

In some cases, the pump handle can “kickback.” Always

keep your body to side of pump, away from line of handle

force.

Do not add extensions to handle. Extensions can cause

unstable operation.

Item Description

1 Jacking Cylinder

2Hose

3 Vent Fill Cap

4Pump

5Valve

6 Jacking Handle

FIGURE 8-6

Loading...

Loading...