Manitowoc Published 10-09-2020, Control # 259-06 7-11

MLC80A-1/MLC90A-1/MLC100A-1/MLC100-1 SERVICE/MAINTENANCE MANUAL POWER TRAIN

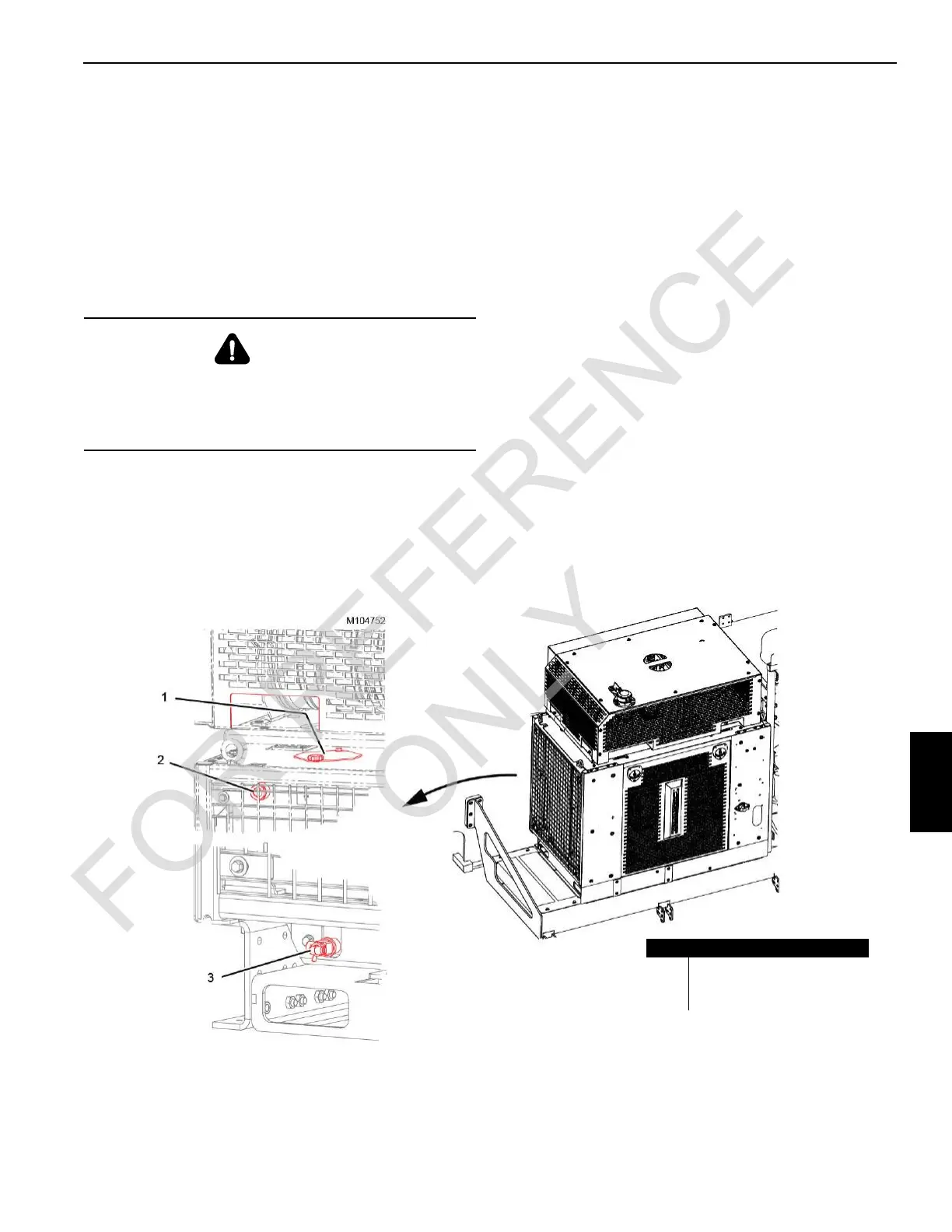

2. Slowly add supplemental coolant additive (SCA) and a

50-50 coolant mixture to the radiator through the fill cap

opening. Refer to the Engine Manufacturer’s Manual for

specific SCA and coolant recommendations.

3. Once coolant is visible in the middle of the sight gauge

(2), wait 2 to 3 minutes before starting the engine to

allow the system to naturally purge entrained air and the

coolant level to stabilize.

4. Add a 50/50 coolant mixture to bring the coolant to the

middle the sight gauge (2).

5. Check that both cab heater valves on the engine are

open.

6. In the cab, place the heat control to maximum.

7. With the radiator fill cap removed:

• Start the engine and operate it a low idle for 2-3

minutes.

• Stop the engine and add a 50/50 coolant mixture to

bring the coolant to the middle the sight gauge (2).

NOTE: After starting a cold engine, increase engine speed

slowly to provide adequate bearing lubrication and

to allow oil pressure to stabilize.

8. With the radiator fill cap removed:

• Start the engine and run it at high idle until the

thermostat opens.

Engine damage can occur if the temperature rises

above 93°C (200°F).

9. Reduce engine speed to low idle for 2 minutes to cool

down the engine components, then stop the engine.

10. Once the engine has cooled to 50°C (120°F), add a 50/

50 coolant mixture to bring the coolant to the middle the

sight gauge (2).

11. Install the radiator fill cap (1).

12. Install the access cover.

13. Operate the engine until it is at its normal operating

temperature and check for coolant leaks Repair as

needed.

WARNING

Chemical and Burn Hazard!

Coolant could spray from an open radiator cap while the

engine is running. Do not stand near the radiator while

operating the engine with the pressure cap removed.

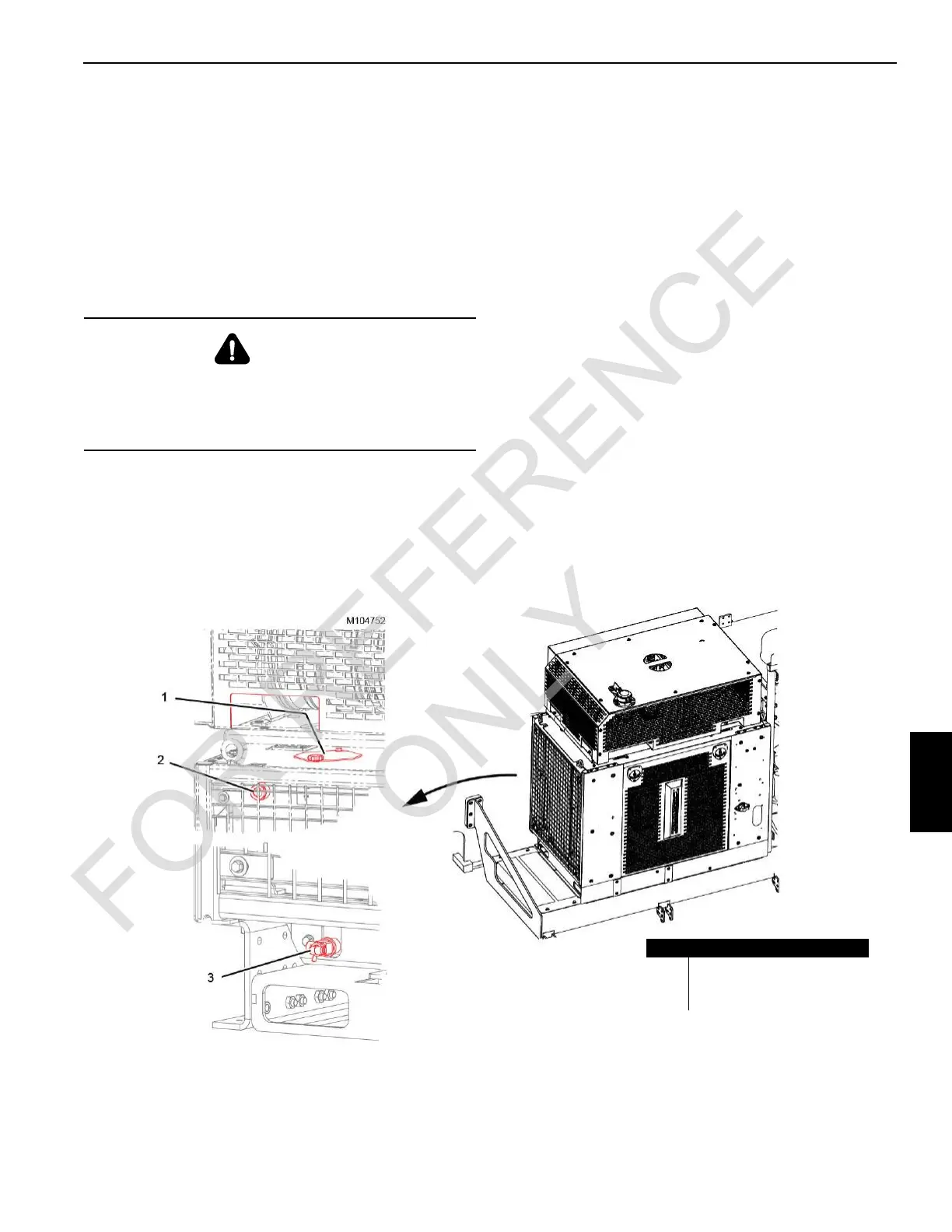

Item Description

1 Fill Cap—1.03 bar (15 PSI)

2 Sight Gauge

3Drain Valve

FIGURE 7-9

Loading...

Loading...