SAFETY INFORMATION MLC90A-1/MLC100-1 OPERATOR MANUAL

2-26

Published 12-10-19, Control # 258-05

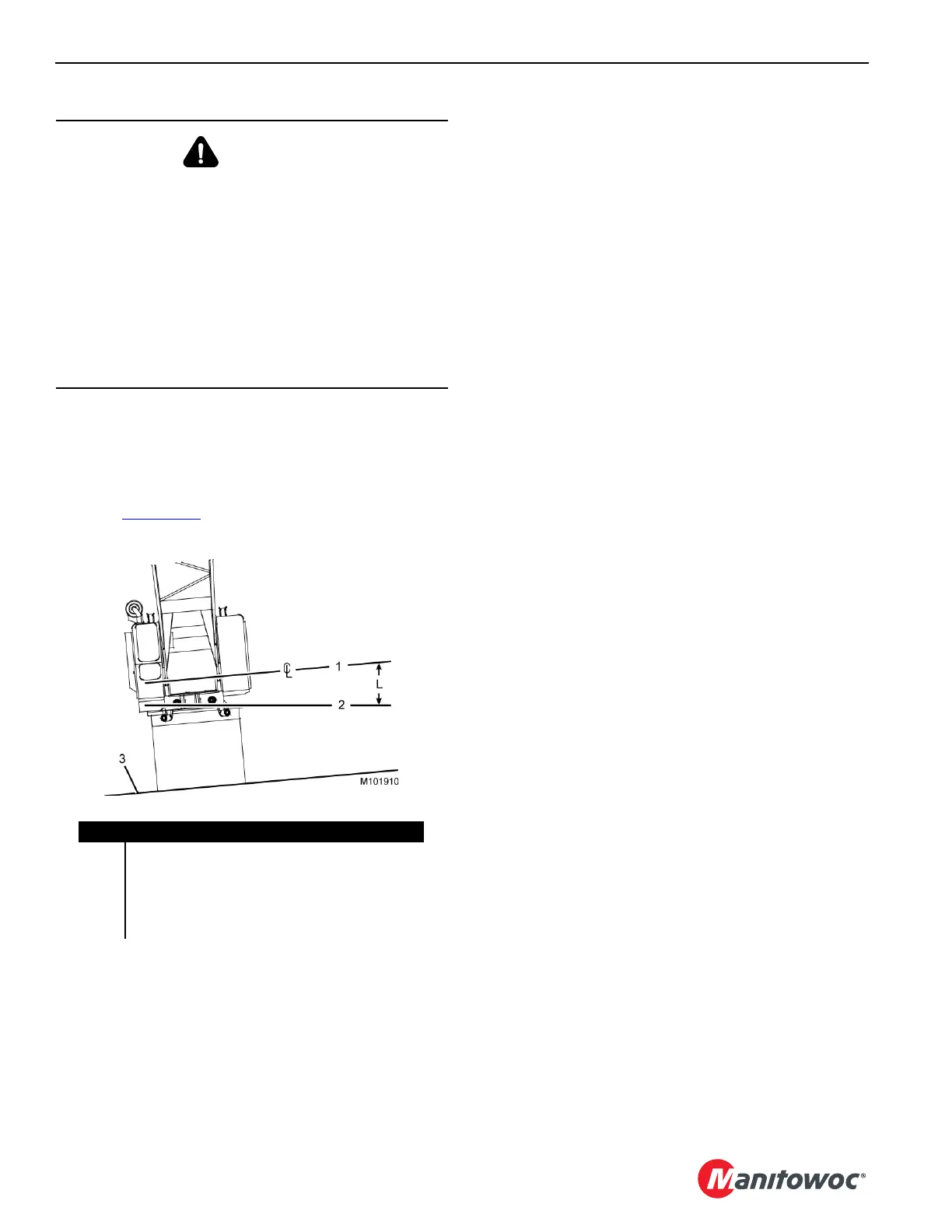

Barge Mount Definitions

1. Machine List, as defined by Manitowoc, is the crane’s

out-of-level condition — from side-to-side — as

measured by the angle between horizontal and a line

drawn through the centerline of the crane’s boom hinge

pins (Figure 2-11

). This out-of-level condition creates

side load and affects the crane’s lifting capacity.

2. Barge List (also referred to as heel or trim) causes swing

out of the load and may produce side load. When

Manitowoc provides a Capacity Chart showing

capacities for a 2 degree machine list for example, we

are referring to the maximum allowable lifting capacity

for the crane when experiencing an out-of-level

condition (side-to-side) of 2 degrees as measured by

angle between horizontal and a line drawn through

centerline of the crane’s boom hinge pins.

Unless otherwise specified in the Capacity Chart, barge

list (heel or trim) must not exceed the machine list

degrees given in the Capacity Chart.

3. Barge List and Machine List are not the same. As the

crane rotates on a barge, barge list (as defined above)

will change. The worst machine list condition generally

occurs when the crane swings over the corner of the

barge, producing maximum side load.

Inspection of Barge-Mounted Crane

To aid in preventing harmful and damaging failure as

previously indicated, regular inspection for signs of

overloading in the following load bearing components is

required. Correct each defect found before placing the crane

into service.

• Boom

• Counterweight

• Backhitch

• Rotating Bed

• Wire Rope

• Pendants and Straps

• Hook and House Rollers

When equipped with hook rollers, it is recommended that

each hook roller assembly be inspected daily for any sign of

overloading, to include:

• Deformation of roller path

• Proper hook roller adjustment

• Deformation or cracks in hook roller hanger

• Bent hook roller shaft

• Damaged bearings

Transporting Crane on Barge

If it is necessary to transport the crane on a barge, ship, or

floating platform when dynamic conditions will be

experienced, the boom must be lowered onto a cradle (or

other support) and the crane’s boom, rotating bed, and

lowerworks must be secured against movement. If the crane

is equipped with a mast, the mast must be securely tied

down with guylines. Failing to take these steps can result in

shock load or side load damage to the boom and mast.

WARNING

Tipping Crane Hazard!

Tie-downs which only prevent the crane from shifting as in

barge, ship or floating platform mounting, may not provide

adequate support when using a Capacity Chart for

pedestal mounting. Before operating a crane on a barge,

a ship or a floating platform, the crane user shall verify

that correct the Capacity Chart is being used — pedestal

mounted, barge mounted, 0°, 1°, 2° or 3° list or dynamic

Capacity Chart.

Failing to use the correct Capacity Chart can result in an

accident.

Figure 2-11. Machine List

Item Description

1 Centerline through Boom Hinge Pins

2 Horizontal

3 Barge Deck

L Degrees of Machine List (Maximum allowable is

specified in Capacity Chart)

Loading...

Loading...