SETUP AND INSTALLATION MLC90A-1/MLC100-1 OPERATOR MANUAL

4-88

Published 12-10-19, Control # 258-05

Winding Wire Rope onto Drum

1. Remove the wire rope from the shipping reel:

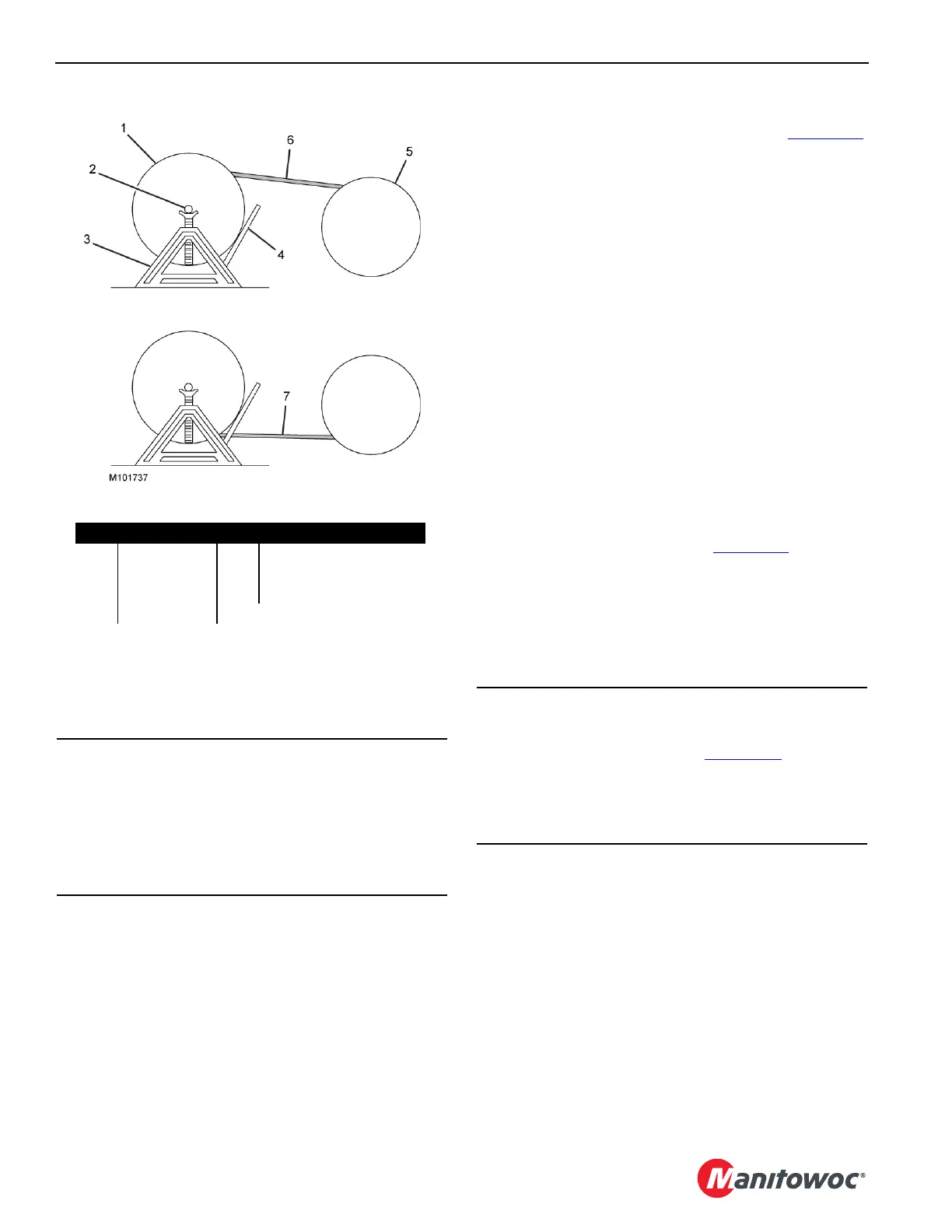

a. Mount the wire rope shipping reel (1, Figure 4-56

)

on a shaft (2) supported at both ends by jacks (3) or

blocks.

b. Provide a brake at the shipping reel so that the wire

rope can be wound tightly on the drum.

c. Avoid a reverse bend when winding the wire rope

onto the drum: wind from the top of the reel to the

top of drum (upper view) or from the bottom of the

reel to the bottom of the drum (lower view).

d. Avoid dragging the wire rope in the dirt or around

objects that can scrape, nick, cut, or crush the wire

rope.

2. Carefully inspect the drums and all rope guides, rollers,

and sheaves for defects that can cause the wire rope to

wear or be cut. If defects cannot be fixed, replace the

faulty parts.

3. Apply tension to the wire rope as it is wound slowly onto

the drum.

a. The first wrap of wire rope must be tight against the

drum flange for the approximately three-fourths of

the drum diameter (View A, Figure 4-57

).

b. Tap the adjacent wraps against each other with a

soft metal or wooden mallet as the wire rope is

spooled onto the drum.

c. Use extreme care not to put twists or turns in the

wire rope. Allow the rope to assume its natural lay.

CAUTION

Avoid Wire Rope Damage

The shipping reel must rotate when the wire rope is

unwound.

Attempting to remove the wire rope from a stationary reel

can result in a kinked wire rope, and the wire rope will be

ruined.

Figure 4-56

Item Description Item Description

1 Shipping Reel 5 Drum

2 Shaft 6 Top to Top Winding

3 Jack Stand 7 Bottom to Bottom Winding

4Brake

CAUTION

Avoid Wire Rope Damage

Voids or spaced wraps (View B, Figure 4-57) in the first

layer will permit movement and a wedging action with the

subsequent layers. Crushing and abrasion of the wire

rope will occur.

Never allow the wire rope to “cross-wind” on the drum.

Loading...

Loading...