AXLES/DRIVE SHAFTS/WHEELS AND TIRES CD5515-2/YB5515-2 SERVICE MANUAL

8-14 Published 1-20-2017, Control# 483-02

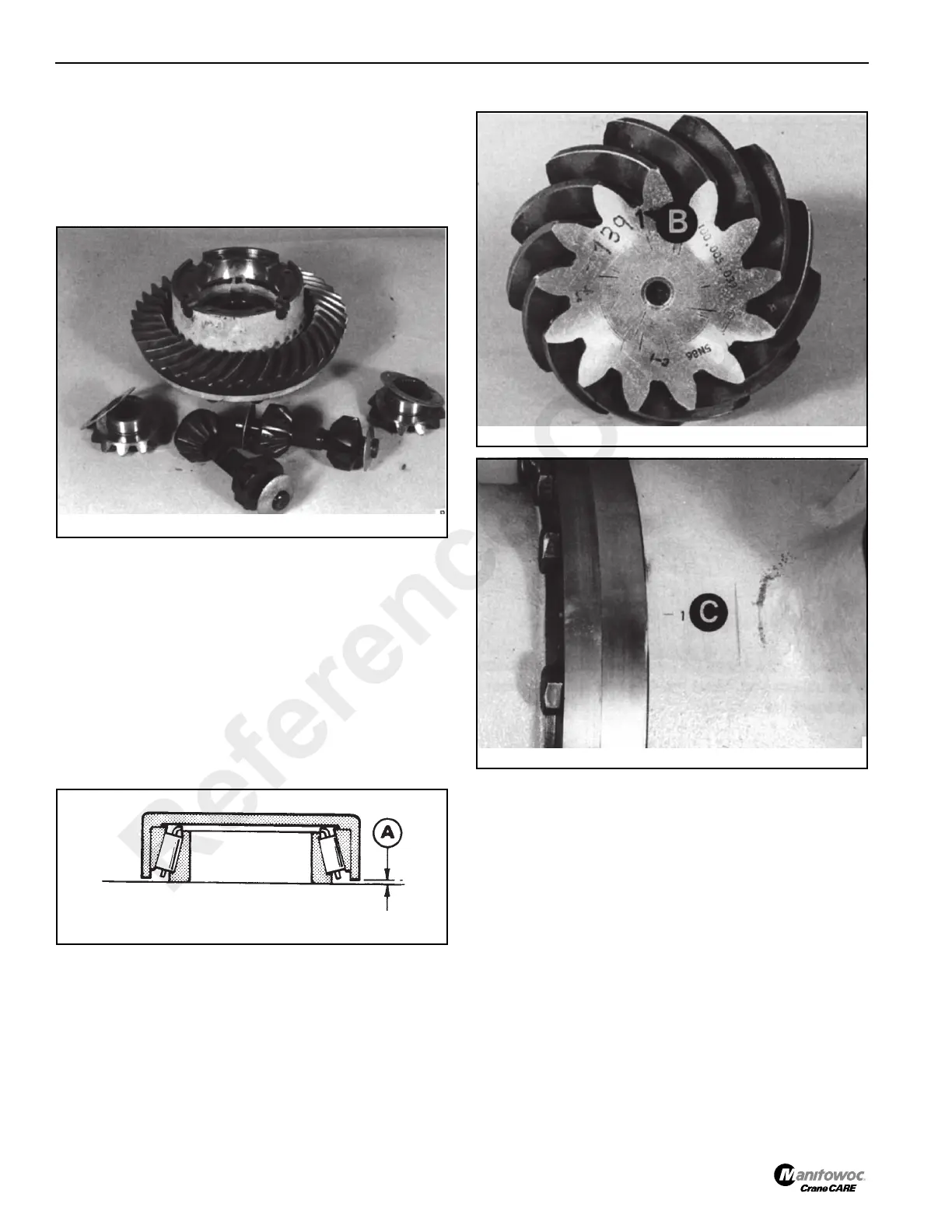

c. Remove the differential gears and spherical

washers Figure 8-24. Pull off both differential

bearing cones.

If required, remove the crownwheel to differential

case half retaining bolts and remove the

crownwheel.

Assembly

Pinion Depth Setting Procedure

Determine the pinion depth setting as follows:

NOTE: See page 8-15 for general guidance on

crownwheel and pinion adjustment.

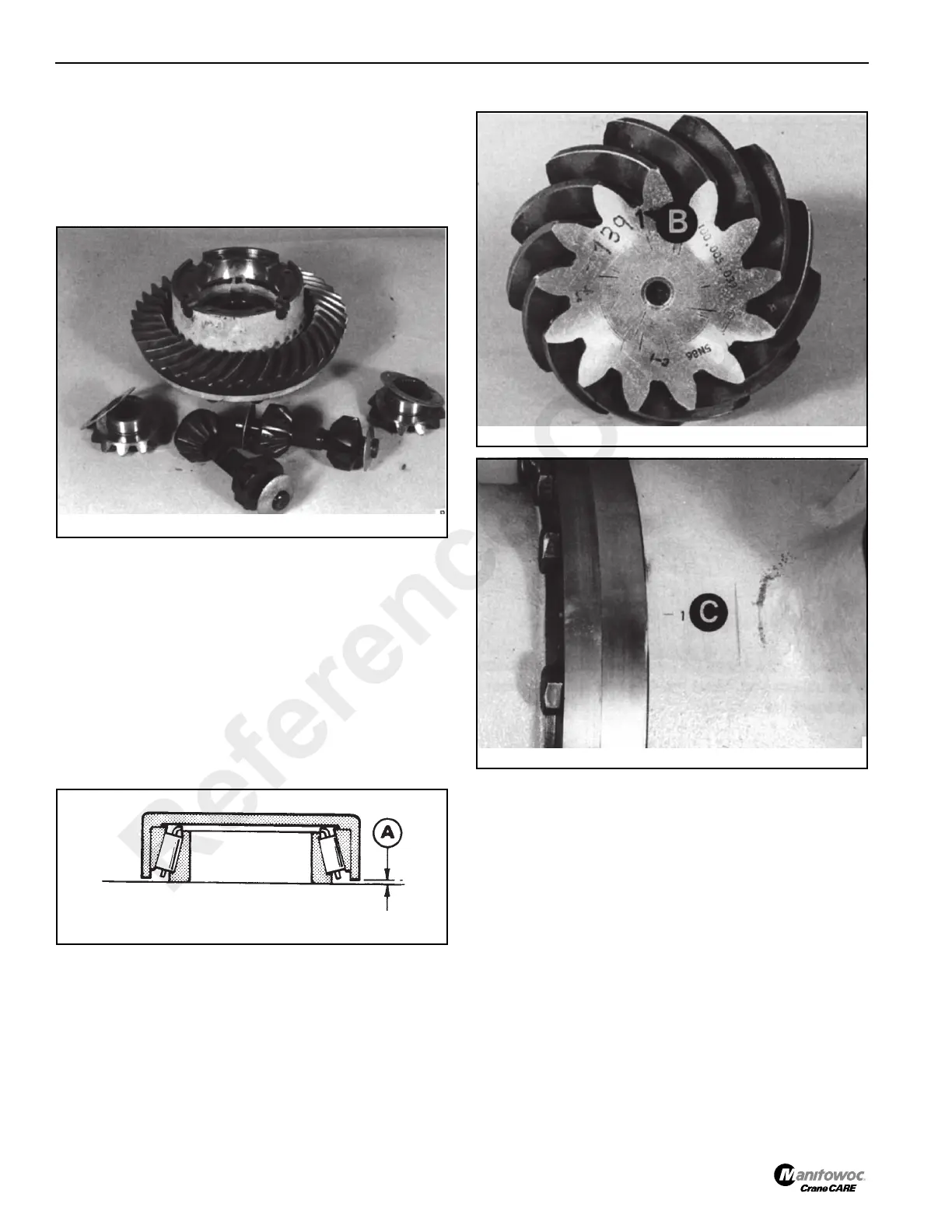

1. Assemble the pinion inner bearing and its cup on a flat

surface.

2. Place the pinion bearing measuring cup over the bearing

assembly Figure 8-25. Measure gap A. Add tool depth of

30.1 mm. (1.18 in) to gap A to give bearing depth.

3. Find the mounting distance value B Figure 8-26 on the

pinion and deviation C Figure 8-27 on the drive head

housing. Both units are in millimeters. To convert

millimeters to inches, multiply millimeters by 0.03937.

4. If dimension B is positive, add it to the bearing depth. If

dimension B is negative, subtract it from the bearing

depth. See example Crownwheel and Pinion Adjustment

on page 8-15.

5. If dimension C is positive, subtract it from the total. If

dimension C is negative, add it to the total. See example

Crownwheel and Pinion Adjustment on page 8-15.

6. Subtract the result from the standard value of 31.19 mm

(1.23 inches) to give the required shim thickness. See

example Crownwheel and Pinion Adjustment on

page 8-15.

Reference Only

Loading...

Loading...