GROVE Published 1-20-2017, Control# 483-02 8-15

CD5515-2/YB5515-2 SERVICE MANUAL AXLES/DRIVE SHAFTS/WHEELS AND TIRES

Example:

Dimensions in Millimeters

Dimension A 0.25

Add to depth +30.01

Total 30.26

Add dimension B, if positive.

(Subtract if negative) +0.01

Total 30.27

Add dimension C if negative.

Subtract if positive (+) -0.01

Total 30.28

Standard Value 31.19

Less Calculated total

from above -30.28

Shim Thickness 0.91

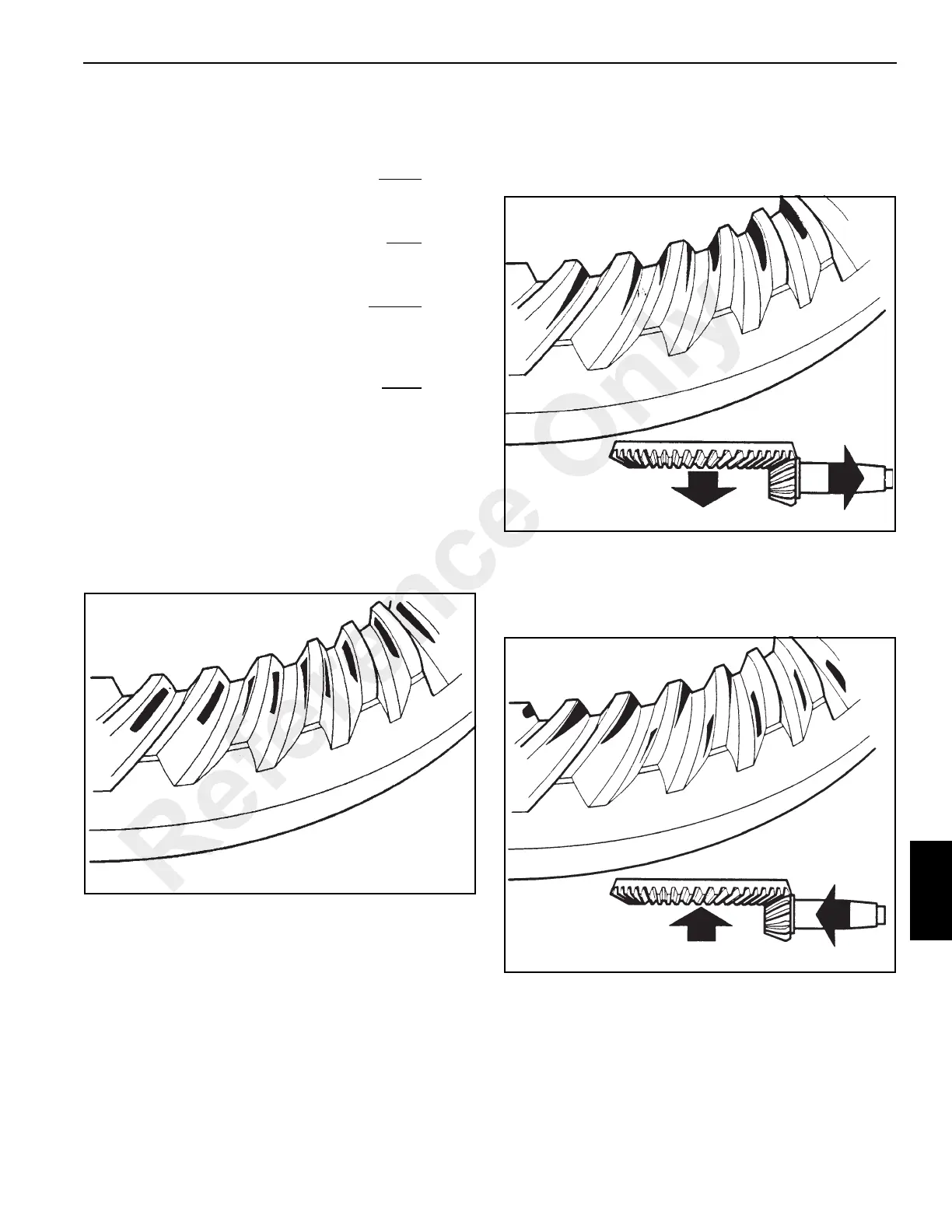

Crownwheel and Pinion Adjustment

Meshing of the gears should be checked by marking three of

the pinion teeth with engineers marking compound and

rotating the pinion.

The marking will then be transferred to the crown wheel

teeth.

Correct teeth marking Figure 8-28

Pinion too deeply in mesh Figure 8-29

Decrease the shim thickness between the pinion inner

bearing cup and the axle casing. Move the crown wheel

towards the pinion to correct the backlash.

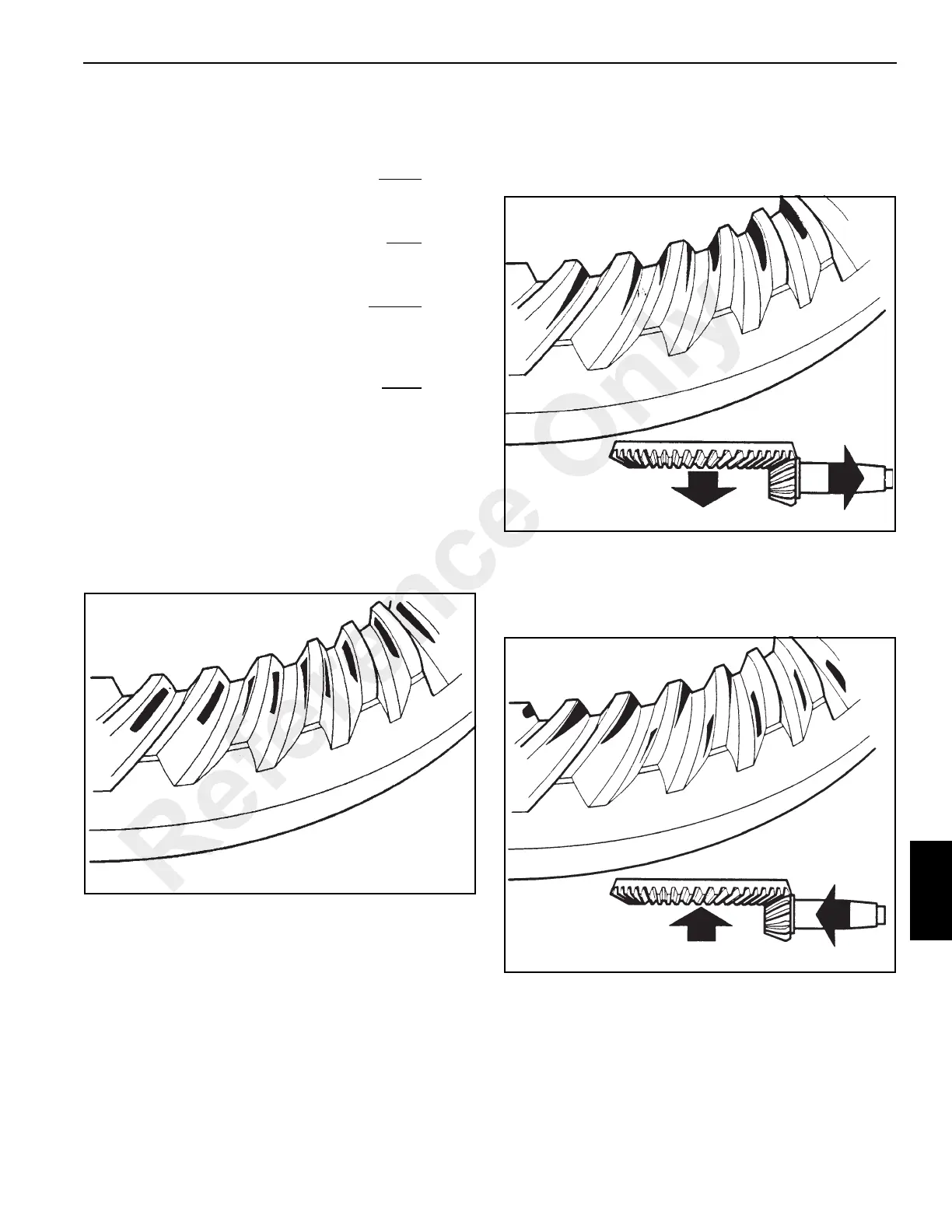

Pinion too far out of mesh Figure 8-30.

Increase the shim thickness between the pinion inner

bearing and the axle casing. Move the crownwheel away

from the pinion to correct the backlash.

Reference Only

Loading...

Loading...