FUEL INJECTION

90-883728 JULY 2001 Page 3B-19

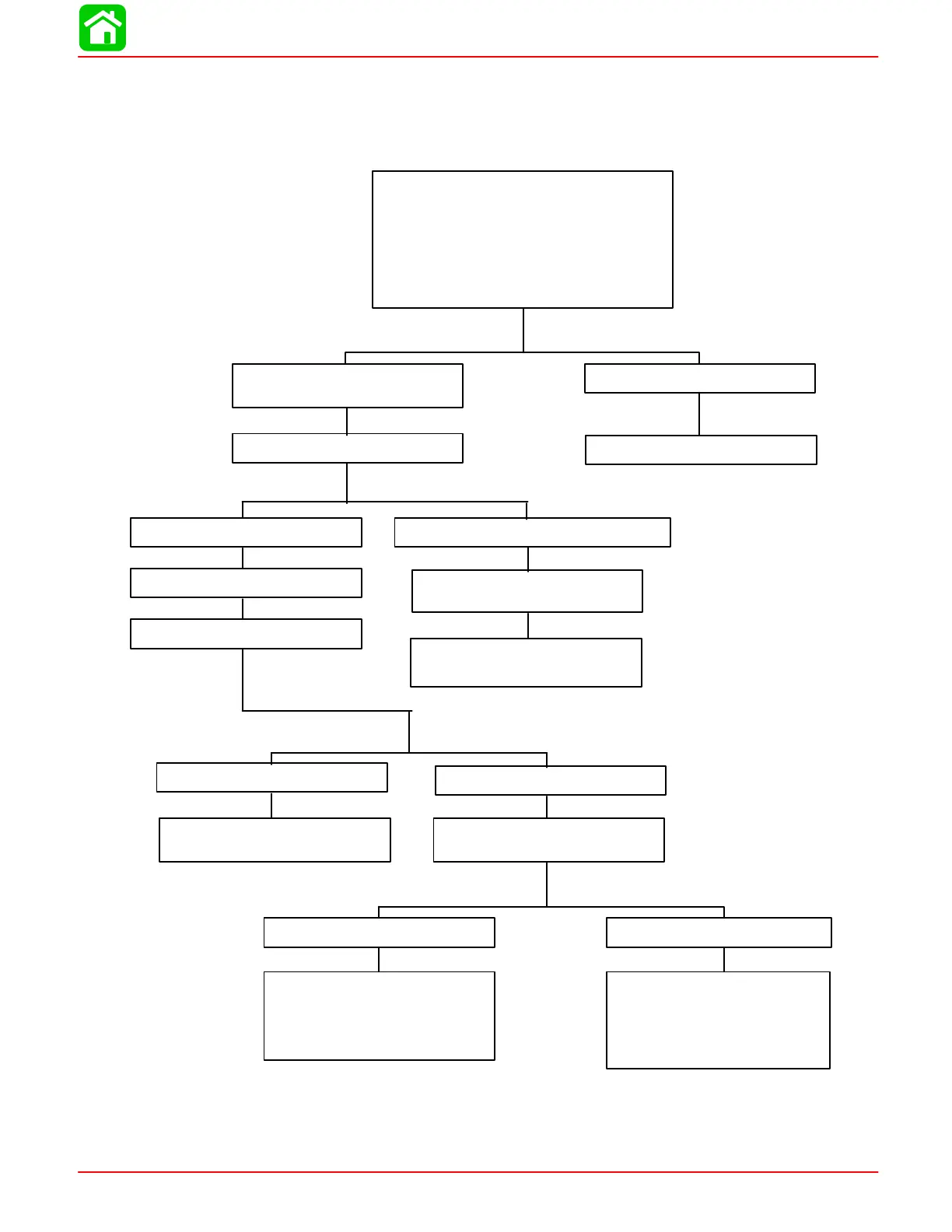

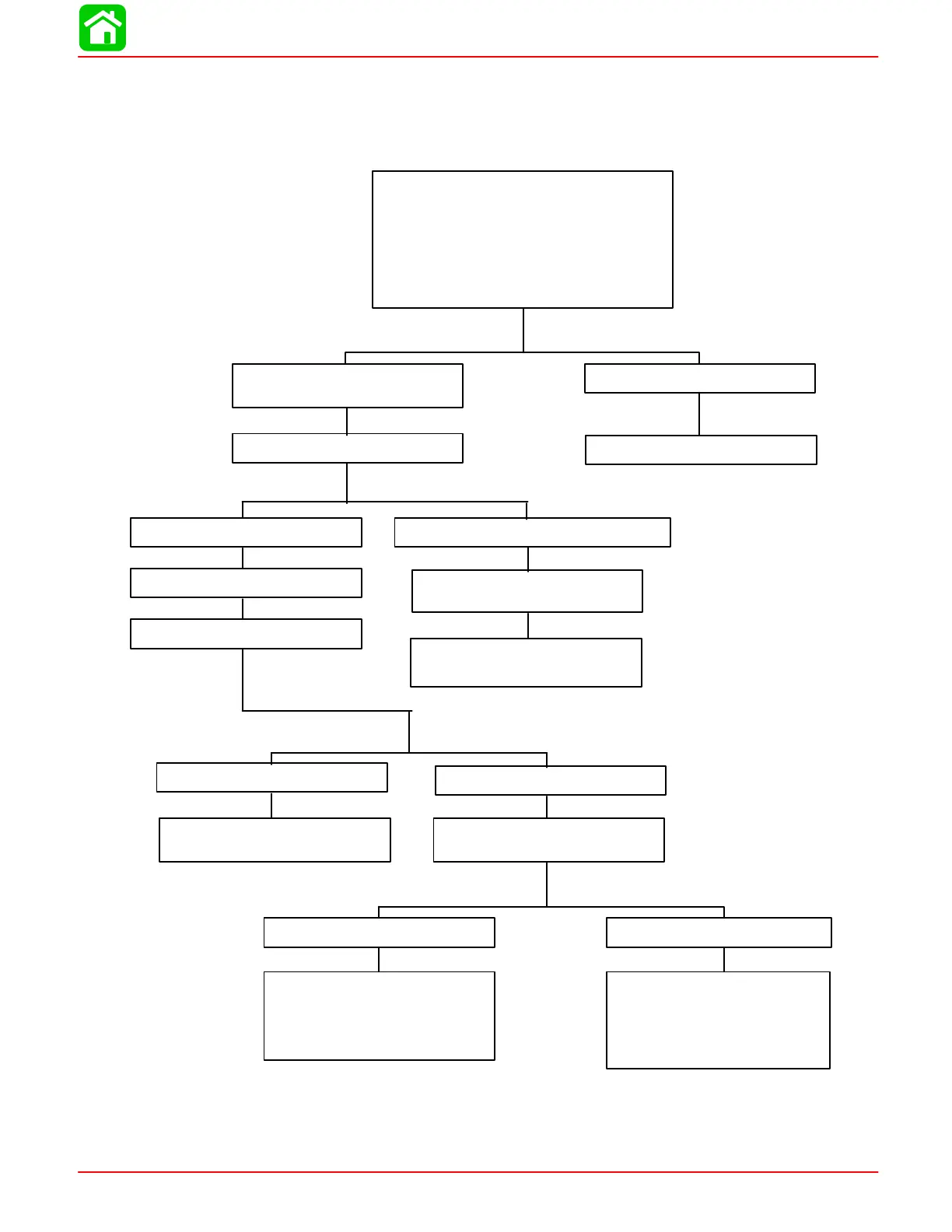

Fuel Rail Electrical/Fuel Determination

• Perform all preliminary checks page 3B-11.

• Adequate fuel pressure (41 to 45 psi; 283 to

310 kPa) follow Low/High Fuel Route Flow

Charts.

• Run engine @ idle and with DDT, perform

cylinder load test.

No RPM change on cylinder(s),

indicating problem in cylinder(s).

RPM decreases (on each cylinder).

Perform Fuel Injector load test.

Fuel delivery OK.

Defective injector or broken cir-

cuit to injector.

Perform Induction Manifold

Disassembly and inspection.

Perform compression check on

problem cylinder.

Low or no compression on cylinder.

Compression OK.

Inspect cylinder bore. Refer to

Section 4 for disassembly.

NOTE: Injector filters must be

inspected prior to reassembly.

Check:

1) Damaged reeds

2) End cap seals

3) Crankcase split line leak

4) Crankshaft sealing rings

Results Results

Results

ResultsResults

Fuel Injector has audible click.

Results

Injector is functioning properly

Results

Fuel Injector does not have audible click.

Perform Ignition Coil load test.

Ignition spark OK

Weak or no ignition spark

Replace defective coil, spark plug

or wiring

Results

Loading...

Loading...