POWERHEAD

Page 4A-42 90-883728 JULY 2001

Cleaning and Inspection

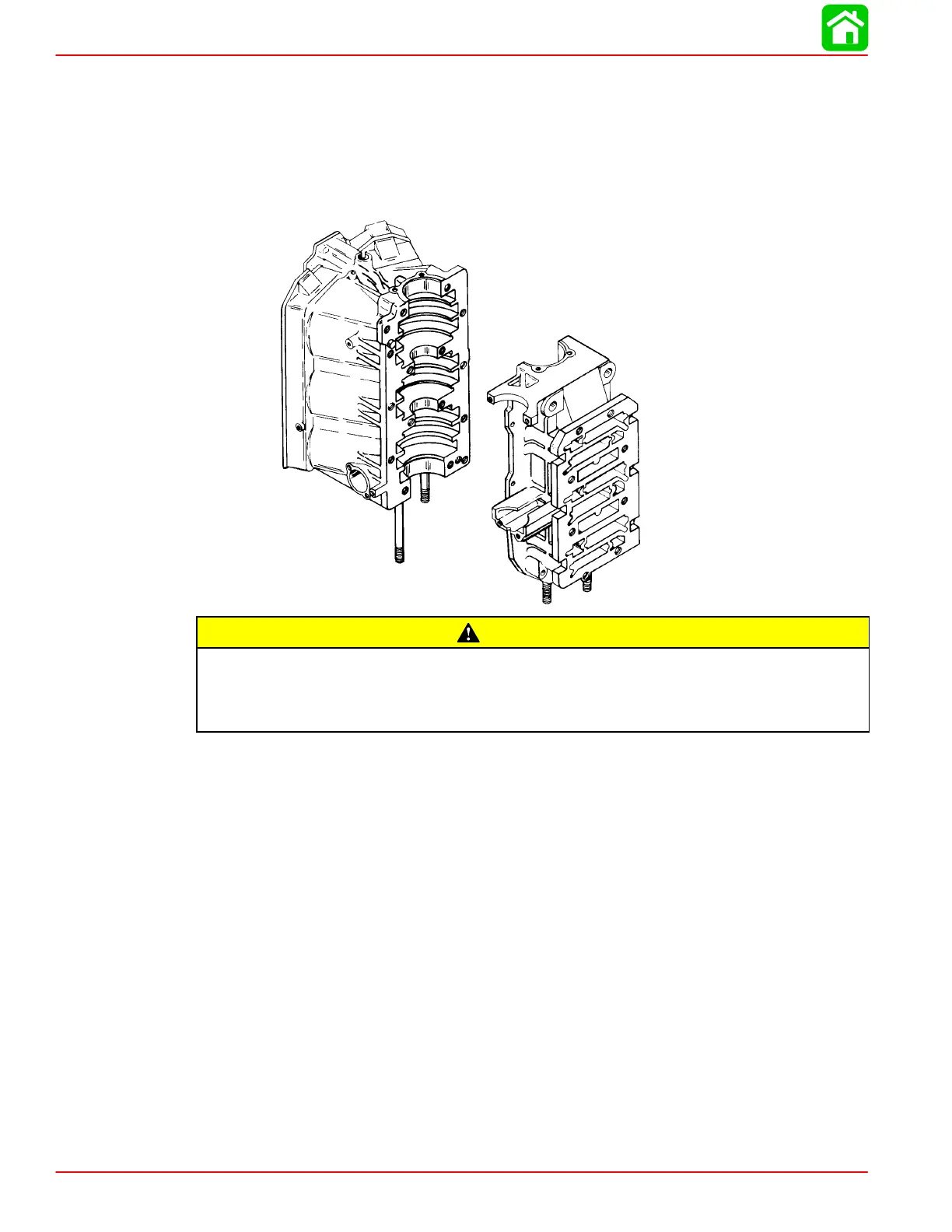

Cylinder Block and Crankcase Cover

IMPORTANT: Crankcase cover and cylinder block are a matched, line-bored assem-

bly and never should be mismatched by using a different crankcase cover or cylinder

block.

CAUTION

If crankcase cover or cylinder block is to be submerged in a very strong cleaning

solution, it will be necessary to remove the crankcase cover/cylinder block bleed

system from crankcase cover/cylinder block to prevent damage to hoses and check

valves.

1. Thoroughly clean cylinder block and crankcase cover. Be sure that all sealant and old

gaskets are removed from matching surfaces. Be sure that carbon deposits are re-

moved from exhaust ports.

2. Inspect cylinder block and crankcase cover for cracks or fractures.

3. Check gasket surfaces for nicks, deep grooves, cracks and distortion that could cause

compression leakages.

4. Check all water and oil passages in cylinder block and crankcase cover to be sure that

they are not obstructed and that plugs are in place and tight.

Special Service Information

Grooves in Cylinder Block Caused By Crankshaft Sealing Rings

Grooves in cylinder block caused by crankshaft sealing rings are not a problem, except if

installing a new crankshaft and the new sealing rings on crankshaft do not line up with exist-

ing grooves in cylinder block. If installing a new crankshaft, refer to crankshaft installation,

Powerhead Reassembly section to determine if powerhead can be used.

Loading...

Loading...