POWERHEAD

Page 4A-50 90-883728 JULY 2001

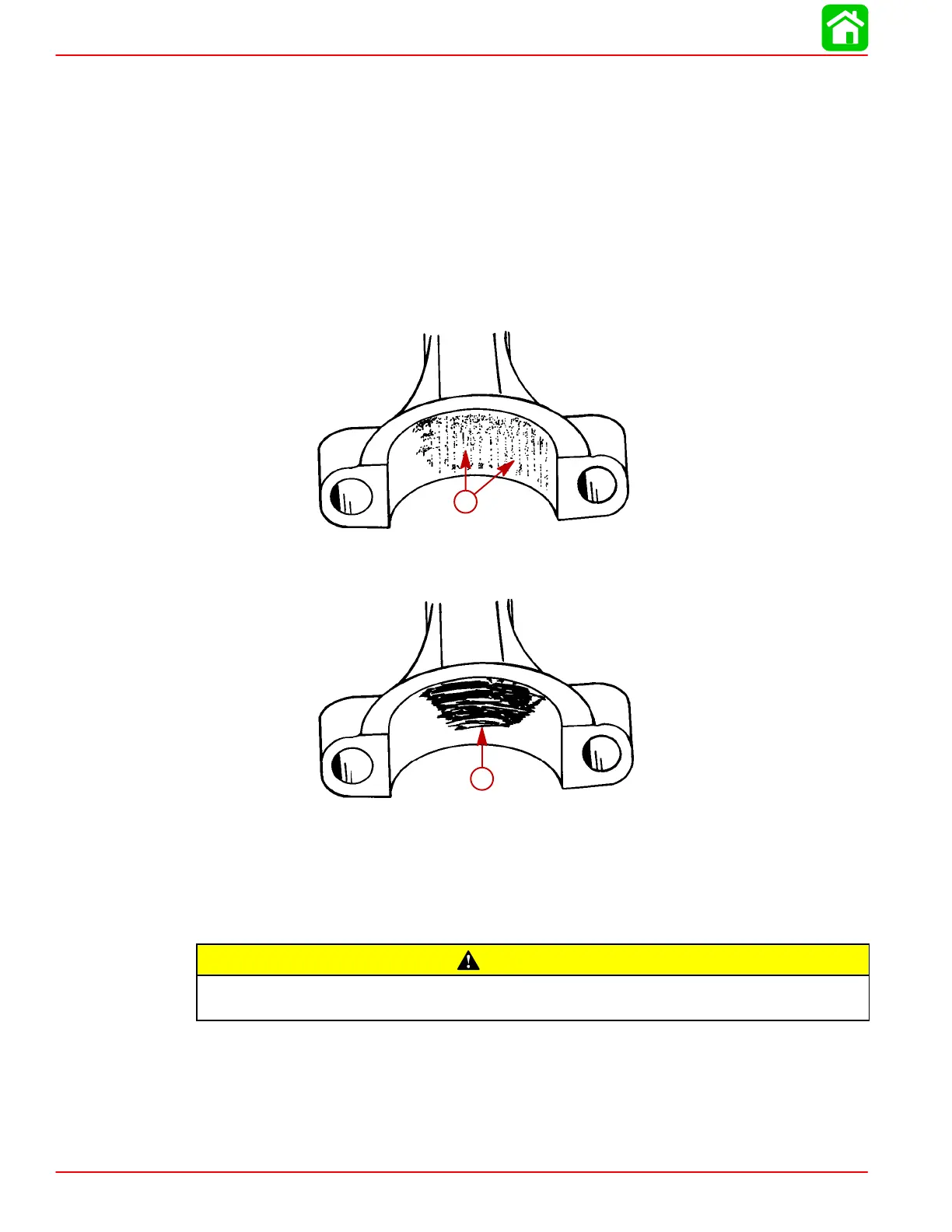

6. Chatter Marks: Chatter marks are the result of a combination of low speed - low load

- cold water temperature operation, aggravated by inadequate lubrication and/or im-

proper fuel. Under these conditions, the crankshaft journal is hammered by the connect-

ing rod. As ignition occurs in the cylinder, the piston pushes the connecting rod with tre-

mendous force, and this force is transferred to the connecting rod journal. Since there

is little or no load on the crankshaft, it bounces away from the connecting rod. The crank-

shaft then remains immobile for a split second until the piston travel causes the connect-

ing rod to catch up to the waiting crankshaft journal, then hammers it. The repetition of

this action causes a rough bearing surface(s) which resembles a tiny washboard. In

some instances, the connecting rod crank pin bore becomes highly polished. During op-

eration, the engine will emit a “whirr” and/or “chirp” sound when it is accelerated rapidly

from idle speed to approximately 1500 RPM, then quickly returned to idle. If the preced-

ing conditions are found, replace both the crankshaft and connecting rod(s).

51853

a

a-Chatter Marks Between Arrows

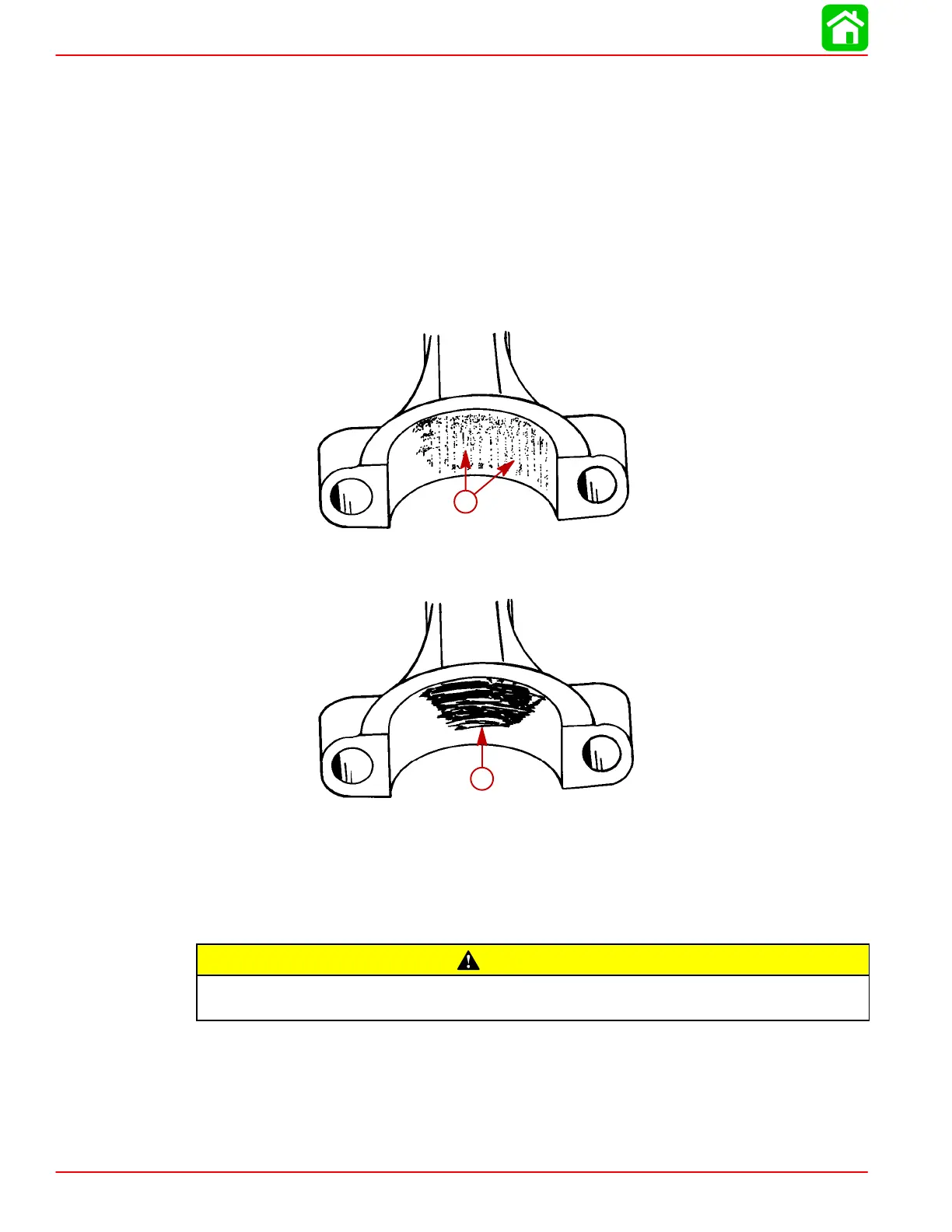

7. Uneven Wear: Uneven wear could be caused by a bent connecting rod.

51853

a

a-Uneven Wear Between Arrows

8. If necessary, clean connecting rod bearing surfaces, as follows:

a. Be sure that “etched” marks on connecting rod (crankshaft end) are perfectly aligned

with “etched” marks on connecting rod cap. Tighten connecting rod cap attaching

bolts securely.

CAUTION

Crocus cloth MUST BE USED to clean bearing surface at crankshaft end of connect-

ing rod. DO NOT use any other type of abrasive cloth.

b. Clean CRANKSHAFT END of connecting rod by using CROCUS CLOTH placed

in a slotted 3/8 in. (9.5 mm) diameter shaft, as shown. Chuck shaft in a drill press

and operation press at high speed while keeping connecting rod at a 90 angle to

slotted shaft.

Loading...

Loading...